亮点

- Greif’s Build to Last Strategy and Protecting Our Future mission embed climate considerations into our day-to-day decision-making and long-term strategic planning.

- We executed a virtual power purchase agreement (VPPA) with Enel Green Power España for 100 GWh of renewable energy annually, enough to offset approximately 65 percent of our electricity consumption in Europe.

- Greif’s land management subsidiary, Soterra, generated 59 percent of its revenue from nature-based solutions and renewable energy initiatives in 2024. We added geological sequestration, utility-scale solar installations, and development of Improved Forest Management carbon offsets to our sustainable forest management practices.

- Greif refined our Scope 3 emissions reduction methodology by conducting a thorough gap analysis to improve the quality of the data and identify new opportunities to engage with our value chain partners to reduce emissions.

- In 2024, our combined Scope 1 and Scope 2 (market-based) greenhouse gas (GHG) emissions were 1,120 thousand metric tons CO2e, compared to 1,108 thousand metric tons in 2023.

气候战略为何重要

Our robust climate strategy is driven by our belief that it is our responsibility to reduce our impact as a manufacturing company. This is also crucial to building and maintaining relationships with our colleagues, customers, partners, and shareholders. Climate change is a top priority for our customers, many of whom have set ambitious climate goals and are working to foster transparency across their operations and value chains. We aim to be the trusted partner that supports our customers in achieving these goals by using data-driven decision-making to provide guidance and recommendations around sustainable solutions. Our climate strategy is integrated into every facet of our business, with an emphasis on driving projects that reduce our emissions. Our product portfolio, which emphasizes manufacturing innovation and performance efficiency, reflects how we are working with customers to provide innovative, low-carbon, and circular products to help them meet their goals.

Our climate strategy is also a vital part of attracting and retaining top talent, which is needed to protect our competitive advantage in the market. We recognize the value of hiring passionate colleagues early in their career and providing a culture where they can innovate and grow. At Greif, we find a strong correlation between business success and employee engagement at all levels of our organization, and our climate strategy is an important component of that process.

Our Approach

We are working to consider and reduce the carbon footprint at each stage of the life cycle of our products, from raw material extraction to end-of-life disposal. Since 2007, we have set ambitious goals to reduce our GHG emissions and energy use, most recently setting a 2030 science-aligned target to reduce our absolute Scope 1 and Scope 2 GHG emissions by 28 percent from a 2019 baseline.

Engaging Greif colleagues is an important part of our climate strategy. To empower action and transparency, every colleague has access to energy dashboards that detail usage performance and help colleagues make more informed decisions that move us closer to our goals. Via Greif University, our internal training and education platform, colleagues also have access to thousands of courses to support them on their sustainability journey. We are working to embed our climate strategy at every level of the organization and value chain because we know success will only be achieved if there is commitment from everyone.

气候变化风险管理

Over the past three years, we have conducted several internal climate risk workshops in which colleagues from varying departments, locations, and backgrounds collaborate to identify, rank, and evaluate regulatory, market, and physical climate-related risks and opportunities. In 2023, we successfully completed a third-party physical risk assessment to deepen our understanding of the climate risks and financial impacts associated with our operations. In 2024, our efforts focused on addressing the data points from this analysis.

Our scenario analysis included three future scenarios, including global temperature increases of below 2°C (Representative Concentration Pathway (RCP) 2.6), 2 to 3°C (RCP 4.5) and over 4°C (RCP 8.5), to identify risk likelihoods and impacts to our operations. The assessment identified precipitation, flooding, and heat stress as key physical risks across our global operations. Please refer to our CDP 报告 了解有关气候情景分析练习的更多信息。

|

风险/机会 |

话题 |

描述

|

|---|---|---|

|

物理风险 |

自然灾害 |

大规模洪水/飓风/地震/风暴等导致关键或有价值的生产设施(一个或多个)的损失。

|

|

物理风险 |

直接环境灾难 |

三角洲、弗里兰和造纸厂等关键设施发生重大气候/天气相关事件,从而引发重大环境事件、金融事件,并可能导致公关/形象问题。

|

|

转型风险 |

碳定价机制 |

碳定价法规(例如限额与交易制度和碳税)正在一些市场(欧洲和北美)对 Greif 产生影响,并且可能在其他地区出现。这表现为一笔可观且不断增长的开支。

|

|

转型风险 |

投资/资本规划效率低下 |

缺乏资源来充分了解监管变化对战略决策和投资的影响可能会导致资本配置不理想。这包括设施比预期更快过时以及投资回报率低于预期。

|

|

转型风险 |

弹性/生产连续性 |

卓越的组织能力、相关的业务弹性、准备和敏捷性将使 Greif 能够更快地恢复生产水平,并在发生中断和灾难变得更加常见时更好地支持同事、客户和社区。

|

|

转型风险与机遇 |

客户偏好的转变

|

对可持续产品的需求正在增加。如果 Greif 未能迅速采取行动应对生产过程中再生材料的使用增加,则可能会减少对 Greif 产品和服务的需求。此外,限制 Greif 产品终端市场(如石油和天然气行业)的气候相关法规可能会限制 Greif 的业务,因为关键市场对其产品和服务的需求会减少。Greif 可以利用这一机会,迅速扩大我们的可持续产品组合。

|

| 转型机会 | 对 Greif 回收业务的影响 | 更宏伟的气候情景依赖于提高钢铁和塑料的回收率。如果定位正确,Greif 或许能够扩大其目前的修复实践规模。 |

|

转型机会 |

弹力

|

与业务弹性、准备和敏捷性相关的卓越组织能力将使 Greif 能够更快地恢复生产水平,并在发生中断和灾难变得更加常见时更好地支持同事、客户和社区。 |

请访问本报告的 风险管理 部分来了解有关我们的企业风险管理流程的更多信息。

气候战略与脱碳路线图

Renewable energy and energy efficiency are key pillars of our climate strategy. In 2024, we increased our focus on procuring renewable energy via VPPAs and on-site solar development. To reduce carbon impacts beyond our value chain, we also leveraged nature-based solutions like geologic carbon sequestration and improved forest management offsets. Please visit the 优先考虑自然 section of the report to learn more about our nature-based solution efforts.

可再生能源

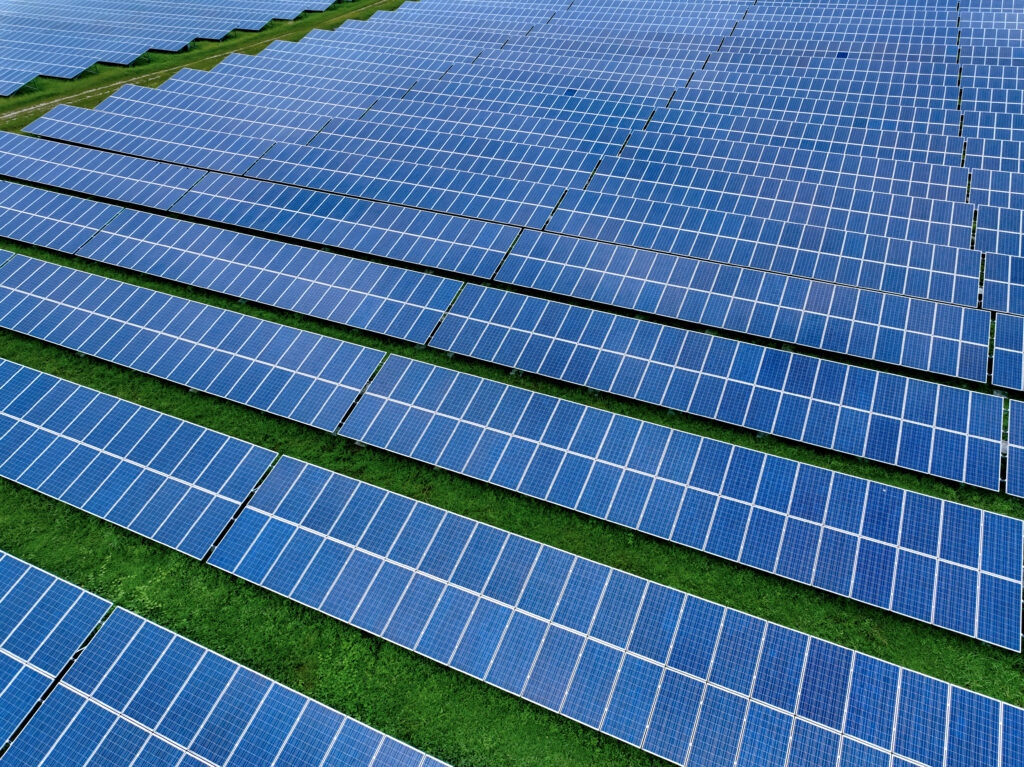

Renewable energy procurement is core to our decarbonization strategy. Meeting the long-term energy-related challenges associated with climate change requires a meaningful shift towards renewables, such as solar, biomass, and wind energy. We strive to identify high-impact opportunities to catalyze our clean energy transition. Since 2016, we have increased our sourcing of renewable energy from both on-site and off-site locations. Greif facilities in North America, Brazil, Chile, China, the Czech Republic, Israel, and the Netherlands are powered by renewable energy, and we recently added rooftop solar to our Singapore facility. Of Greif’s total energy consumption in 2024, 16 percent (892 MWh) came from renewable energy sources such as biomass and solar energy. We will continue to identify and capitalize on additional opportunities to procure renewable energy.

Over the past three years, we conducted an extensive exploration of renewable alternatives to overhaul our electricity and natural gas consumption. As Greif’s Scope 2 emissions make up about half of our total Scope 1 and 2 emissions, switching to renewable energy would eliminate a significant portion of our overall emissions. In 2024, we signed a pivotal contract with a developer for a large VPPA project in Spain, to supply renewable energy for our European operations.

Virtual Power Purchase Agreement with Enel Green Power España

In 2024, Greif announced the signing of a virtual power purchase agreement (VPPA) with Endesa’s renewable subsidiary, Enel Green Power España (EGPE). Through the VPPA, Greif will purchase approximately 70 percent of the projects’ output, which will lead to approximately 100 GWh annually and measurable progress towards our long-term sustainability and climate goals. The solar VPPA is a significant step toward achieving a reduction of our Scope 1 and 2 greenhouse gas emissions by 28 percent by 2030, compared to a 2019 baseline. The renewable electricity generated by the project represents approximately 65 percent of Greif’s Scope 2 emissions in Europe and approximately 3 percent of our global Scope 1 and 2 emissions. By adding renewable energy to the Spanish grid, this initiative drives meaningful emissions reductions and supports a cleaner energy future. To read more about this project, please see the press release.

We are also working to increase renewable energy adoption via solar lease development. Greif is rapidly scaling our solar programs, with 50,000 acres of Soterra-managed land included in lease options with 13 different solar energy developers working on 22 projects. One project, a 100 MW solar farm in Louisiana, started construction in 2024. Please visit the 优先考虑自然 section of the report to learn more about our renewable energy procurement efforts.

能源效率

The role of energy efficiency in capital deployment is key to achieving our energy usage goals. We incorporate ESG criteria into our capital allocation system, placing priority on cost savings, reduced energy consumption, minimized raw materials usage, and improved health and safety for both people and products.

Greif colleagues regularly look for new opportunities to advance technology and conserve energy as part of our culture of continuous improvement. Our energy efficiency projects include equipment upgrades and process optimizations designed to strategically curb energy demand. In 2024, we implemented 58 energy efficiency projects, saving an estimated 35,000 MWh. Additional energy efficiency projects are routinely initiated by Greif’s Lean Six Sigma program.

Another success for the company has been our focus on LED lighting retrofits. We are actively working to retrofit our facilities to at least 80 percent LED lighting to conserve energy, reduce emissions, and create a safer and more pleasant work environment for Greif colleagues.

Energy Efficiency Across Our Operations

Throughout 2024, teams at our facilities drove innovative projects that demonstrate excellence in energy efficiency, cutting energy costs, improving efficiency, and support our sustainability goals. Greif Singapore converted a lithographic coating oven into an internal-lined ends line with an automated spraying system. The project is estimated to save more than 550 MWh per year while improving operational efficiency and capacity. Greif Saudia Arabia installed a logic timer system to manage two motors, controlling an automatic shut off during changeovers, breaks, and other periods of inactivity. These are just two examples of our colleagues’ efforts to integrate sustainability and business objectives into our operations.

For more information about our energy efficiency projects, please see sections 7.55 of our 2024 CDP Climate Response.

循环经济

At the heart of our climate strategy is an emphasis on circularity, specifically increasing the recyclability of our products, expanding our reconditioning network, implementing downgauging techniques, increasing the use of recycled raw material content in our products, and effectively managing waste.

In addition to reducing Scope 1 and 2 emissions, circularity initiatives also reduce our Scope 3 emissions linked to raw material extraction and converting, transportation, and waste sorting and processing and end of life management of our used products. Additionally, these initiatives minimize the amount of material we send to a landfill, thereby decreasing our production of landfill gas, an especially potent mix of greenhouse gases released during decomposition. We currently divert 87 percent of our waste away from landfills and aim to increase that percentage where possible.

请访问本报告的 浪费 section to learn more about our waste management efforts. Please visit this report’s 循环制造 和 创新 部分来进一步了解我们为推动循环经济发展所做的努力。

Supply Chain Emissions

Through our Global Supply Chain (GSC) Sustainability Program, we operationalize our commitment to reduce carbon emissions throughout our supply chain. Reduction projects are prioritized and embedded into three key areas of influence: energy procurement, logistics networks, and raw material sourcing.

Our energy procurement managers lead or collaborate in our renewable energy sourcing projects. Sourcing managers identify opportunities for emissions reduction through supplier collaboration, product ideation and trials, and purchasing decisions. Our logistics managers manage projects to increase efficiency in our global transportation and logistics networks.

In 2024, we conducted a thorough analysis of our Scope 3 emissions to develop a pipeline of strategic reduction activities and projects for the medium- to long-term. We evaluate projects based on our level of influence and impact, prioritizing projects we can directly execute within our organization. We are incorporating indirect projects into engagement plans we are building to inform our work with carriers, suppliers, and third-party partners.

请访问本报告的 全球供应链管理 部分来了解有关我们整个供应链工作的更多信息。

Goals, Progress, & Performance

2030年目标:

- 与 2019 年基线相比,将范围 1 和范围 2 的绝对温室气体排放量减少 28%。

- 与 2019 年相比,每单位生产能耗减少 10%。

We partnered with a third party in 2020 to conduct an evaluation of our ability to achieve a Science Based Target Initiative (SBTi) aligned goal. The analysis led to Greif’s public commitment to a 28 percent reduction in absolute Scope 1 and Scope 2 emissions by 2030, based on a 2019 baseline. Aligned with prevailing climate science, this target aims to limit global warming below 2°C. While we are not yet able to provide a detailed analysis of our absolute progress against this goal due to acquisitions and ongoing data improvements, our 2024 Scope 1 and Scope 2 (market-based) absolute emissions increased by about 1 percent compared to 2023.

In 2024, we made progress through renewable energy procurement, nature-based solutions, and energy efficiency efforts. We also analyzed our Scope 3 emissions and, though we cannot set a Scope 3 target at this point in our sustainability journey, we are working to tackle these emissions while building resiliency in our supply chain. Further, Greif took our first steps in expanding ISO 14001 certifications to additional sites. ISO 14001 provides a management system framework for Greif to integrate climate change efforts into the day-to-day operations at each site on a granular level.

An amendment to ISO 9001 certifications was introduced in 2024 which integrates climate change considerations into organizational management systems. Greif’s operations team has been working to incorporate this into our ISO 9001 certification process. We actively seek opportunities to collaborate with our suppliers, customers, and other stakeholders to reduce our emissions and advance our climate strategy.

能源和温室气体排放数据

| 2020 财年 | 2021 财年 | 2022 财年 | 2023 财年 | FY 2024 | |

|---|---|---|---|---|---|

| Total Energy Consumption (MWh) | 5,423,000 | 5,832,000 | 6,145,000 | 5,594,000 | 5,450,600 |

| Energy Reduction per Unit of Production, compared to Baseline1,2 | - | -0.30% | -2.30% | -5.50% | 3.70% |

| 2020 财年 | 2021 财年 | 2022 财年 | 2023 财年 | FY 2024 | |

|---|---|---|---|---|---|

| GHG Scope 13 | 693 | 697 | 756 | 605 | 625 |

| GHG Scope 23 (Location-based) | 590 | 557 | 565 | 494 | 476 |

| GHG Scope 23 (Market-based) | 597 | 569 | 578 | 503 | 495 |

| 温室气体范围 3 | 4,148 | 4,357 | 5,019 | 5,062 | 5,144 |

| GHG Total Scope 1, 2, & 3 (Location-based) | 5,431 | 5,611 | 6,340 | 6,161 | 6,245 |

| GHG Total Scope 1, 2, & 3 (Market-based) | 5,438 | 5,623 | 6,353 | 6,170 | 6,264 |

智利 Greif Pudahuel 实现 100% 可再生能源

Greif 位于智利的 Pudahuel 钢铁厂是我们在拉丁美洲第一家 100% 使用可再生能源的工厂。通过与能源供应商 IMELSA ENERGIA 合作的为期两年的项目,该工厂能够将其全部电力供应转向 100% 可再生能源。该工厂为化学品、润滑油和食品饮料市场生产大型钢桶、锥形桶和水瓶。这一转变推进了我们的可持续发展战略,支持我们 2030 年的温室气体减排目标,并有助于支持我们客户的范围 3 减排目标。

Enel X 需求响应

自 2011 年以来,Greif 一直与 Enel X 合作参与需求响应 (DR),Enel X 是 Enel Group Worldwide 的一个部门,后者是一家跨国电力公司,也是全球电力和天然气市场的领先综合企业。Enel X 的需求响应和实时能源监控使公司能够获得市场机会,从而将灵活性货币化、提高运营可靠性并突出可持续发展方面的进步。Greif 已累计获得超过 $440 万美元的需求响应收益,其中包括过去三年的 $130 万美元。大约有 17 家 Greif 工厂与 Enel X 一起参与了需求响应。我们正在评估以确定站点是否符合参与需求响应的资格和合适人选,以扩大我们对该计划的参与。

LATAM Tigre 能源研究

Greif 的 LATAM Tigre 工厂对所有拉丁美洲工厂进行了多学科评估,旨在到 2025 年实现单位产量能耗与 2019 年基线相比降低 6%。确定并评估了所有耗电的机器、外围设备、通用设备和元件,发现整个 LATAM 有 447 个能源重点领域。从这些重点领域中,确定了 70 个战略能源项目。截至 2023 年 11 月,LATAM 已完成 6 个能源效率项目,每年节省能源成本 $29,300,每年减少能源使用量 63,000 千瓦时。