亮点

- Greif encourages all colleagues to participate in the innovation and transformation of our product portfolio and organizational processes. Through our In-House Entrepreneur program, colleagues are empowered to explore new ideas and bring them to life.

- We aim to select projects based on the following criteria: overall value to Greif and our customers, potential financial return, and the sustainability impact.

- We work collaboratively with suppliers and customers to find innovative solutions to their pain points.

创新为何重要

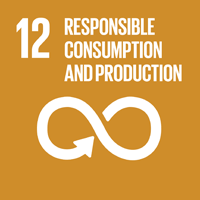

Product innovation is central to our pursuit of delivering quality products and legendary customer service. Our approach to innovation is aligned with our Build to Last Strategy and its core mission of Protecting Our Future, which encourages the development of new, more sustainable products and services that ultimately help advance a low-carbon and circular economy future. Our innovation approach is also aligned with our mission of Creating Thriving Communities, which enhances colleague safety and safeguards customer health through the continuous advancement of process innovation. Our innovative solutions inspire creativity, cultivate colleague engagement, and promote safety internally while bringing value to customers externally by increasing product efficiency, quality, sustainability, and more.

We understand environmental impacts occur across the value chain of our products. Our approach to innovation aims to support decarbonization and circular solutions through incorporating recycled content, enhancing product recyclability, increasing durability, optimizing resource efficiency, and offering end-of-life solutions.

Our Approach

At Greif, we encourage all colleagues and strategic business units to participate in innovating and transforming our product portfolio and organizational processes. We brief our Executive Leadership Team regularly about projects, innovation priorities, industry trends, and other considerations that could impact business operations. Led by the Director of Sustainable Innovation and comprised of representatives from each strategic business unit and corporate function, our Global Innovation Team facilitates idea-sharing and cross-enterprise collaboration.

Our innovation strategy takes a holistic approach, integrating environmental, social, and financial criteria to develop our sustainable packaging solutions. Aligned with the principles of circularity and dematerialization, we work with customers to develop products that meet performance and safety standards while minimizing environmental impacts, thereby increasing customer value. We prioritize creating sustainable products that have a lower carbon footprint, minimize environmental impact, and incorporate more recycled raw materials. We are dedicated to reducing single-use plastic and non-recyclable products by advancing recycled material-based alternatives and eliminating plastic through our innovative barrier coatings.

EnviroRap

Launched in 2024, EnviroRAP is an innovative product developed through our In-House Entrepreneur Program. This sustainable packaging solution is made from repulpable and recyclable material and is designed for use in restaurant take home boxes. Unlike traditional poly-coated packaging, EnviroRAP offers a more sustainable yet cost-effective option. In line with our history of applying circularity principles to our products, EnviroRAP can be returned to our mills and recycled.

Innovation is a driving force behind our product development and circularity efforts. We strive to make products that reduce our impact on the planet while collaborating with internal and external customers to explore creative and innovative solutions to their challenges. In line with this, we are concentrating on implementing product life cycle assessments to advance our circularity strategy and increase transparency around the sustainability of our products. Our focus on product life cycle has encouraged us to think creatively about post-consumer resin products, reconditioning, plastic treatment, and alternative barrier solutions. For more information on our circularity initiatives, please see the 循环制造 本报告的部分。

莫德卡恩

Launched in 2024, the ModCan is a customer-driven innovation designed to improve waste management through increased safety and efficiency. Designed for laboratory waste and other environmental remediation by-products, the ModCan optimizes space utilization by increasing the number of carboys that fit in drums. Greif engineered this innovative product to emphasize ergonomic safety and versatility while retaining compatibility with traditional drum systems. The ModCan saves up to 42 percent of CO2e emissions compared to traditional labpacks and increases drum utilization from the ‘old way,’ which only uses 36 percent of the drum to the ‘new way’ that optimizes the drum by using 82 percent of the space.We offer opportunities for our colleagues to engage in innovation. Our In-House Entrepreneur Program provides colleagues with opportunities to contribute innovative ideas through a simple portal on Greif’s intranet. Colleagues can submit as many ideas as they want, and if selected, the Innovation Team works to develop the idea through several steps and trials. Our Innovator of the Month recognition program acknowledges and celebrates colleagues who contribute significantly to our innovation initiatives through interviews, pictures, and articles explaining in-house entrepreneurs’ work and innovations.

同事参与创新

At Greif, we actively encourage our colleagues to engage in innovation and entrepreneurship. We strive to create an inspiring, dynamic, and engaging work environment that promotes creative problem-solving and continuous learning. All colleagues, including those in traditionally operational roles, have the freedom to explore, take risks, and learn from failures. Our Innovator of the Month and In-House Entrepreneurs programs reflect our commitment to engaging colleagues in finding innovative solutions to challenges faced by our customers and industry. When new ideas are presented, Greif applies a lean start up methodology, rapidly developing a minimum viable product and gathering customer feedback before committing additional resources.

Our Innovation Team regularly monitors progress on our innovation objectives, meeting frequently to share updates and align priorities. Innovation plays an important role in protecting the health and safety of our colleagues; the team collaborates with colleagues to develop solutions and implement technologies that make processes safer. In 2024, the reorganization of the company streamlined our approach, enabling us to drive product innovations that are poised to make a global impact.

Goals, Progress, & Performance

Through collaboration with customers and internal stakeholders, Greif aims to improve our products and gain firsthand insights into unmet customer needs to inform future innovation strategies. Our Global Innovation Team is proactively engaging customers by working with Greif’s commercial teams and increasing customer site visits. Innovation is critical to providing legendary customer service. We aim to track the shift in revenue streams that is generated specifically from these innovations. In 2024, $991 million of our revenue was generated from sustainability-tagged products within our legacy Global Industrial Products and our Life Cycle Services businesses.

IBC 上的激光标记

Greif Sweden/Nordic 是市场上第一家在中型散装容器 (IBC) 上用激光标记取代喷墨标记的公司,从而减少了生产过程中溶剂型油墨的使用。通过消除溶剂和油墨的使用,生产环境更加清洁。我们还能够通过移除传统上用于激光标记的板材,将 IBC 的重量减轻一公斤。我们相信这项创新将为 IBC 上的标记树立新的标准。

油桶的轻量化和造型创新

2015 年,Greif 制造了我们首款重量更轻的 20 升和 25 升油桶模型。这种设计比之前的型号轻 15%,同时保持了之前设计的性能规格。由于重量减轻,新油桶在生产过程中使用的材料和能源减少了高达 15%,并减少了排放影响。2019 年,我们扩大了该产品线,包括 16 升和 18 升尺寸。我们现在在意大利、以色列、瑞典和新加坡生产我们的轻型油桶。

ECOEX 油桶

COEX 多层塑料包装将多层不同的塑料材料组合成一个单一结构,具有许多阻隔性能优势,尤其适用于农用化学品和食品包装应用。然而,重新研磨后,COEX 塑料只能用于低性能应用。为了满足客户对具有卓越阻隔性能的可回收包装的需求,我们创建了 ECOEX 系列油桶。ECOEX 技术使 Greif 能够生产创新的多层油桶,该油桶可通过再研磨工艺回收,以生产高性能、经联合国认证的油桶和瓶子。ECOEX 还为我们的客户降低了成本,因为客户在使用后通常会为 COEX 包装收集支付更高的收集费。我们继续推动创新,以支持我们的循环经济战略并满足客户的需求。LATAM GIP 团队因其在满足客户需求的同时为我们的循环经济战略做出的贡献而荣获 2021 年 Michael J. Gasser 可持续发展奖。

更轻松的方法

为了满足客户减轻重量和优化运输成本的需求,我们的格瑞夫拉丁美洲同事设计了一种新颖的塑料桶创新,采用前所未有的多面侧壁方法处理大型塑料桶。这项改进在保持性能的同时,减少了桶中高达 14% 的树脂。该设计不仅减少了原材料的使用,还优化了托盘利用率,因为它的独特配置允许在与传统设计相同的空间内运输更多桶。多面桶是一种更可持续的解决方案,既可以减少自然资源消耗,又可以降低运输过程中基于化石燃料的原材料使用量和二氧化碳排放量。2 运输过程中的排放。

使用 Drum 360 打造更好的品牌

在 Greif,我们现在有能力 打印高分辨率图像 directly onto steel drums using the latest print technologies. This capability is the direct result of an investment designed to meet the needs of customers who are looking for ways to differentiate their products and generate impactful packaging design to support the price point of high value products. In addition to adding value for our customers, this process eliminated the need for a standard gas oven, using LED-based UV curing during the production process. This new process saves 0.5 kilograms CO2 per drum. Greif strategically placed the new Drum 360 technology in plants close to customers who use this new technology, in the Belgium, France, Netherlands, Italy, Germany and Poland.

GCUBE Connect:实时跟踪您的 IBC

格雷夫 GCUBE 连接 解决方案, 推出 在 LogiChem 虚拟会议上,通过应用基于物联网的设备提供有关客户 IBC 的实时跟踪信息。基于客户的仪表板实时显示 IBC 的位置、已填充产品的水平和环境温度。该仪表板允许客户提前计划已填充产品的交付和新 IBC 的到达,以及安排空 IBC 的收集。GCUBE Connect 还支持更好地管理 IBC 中的残留物。进入设施的每个 IBC 都会自动称重,以确定容器中有多少残留物,以确定如何处理。这项创新与 Greif France 能够从客户供应链上的任何站点(而不是一个单一地点)提取和运送翻新的 IBC 的能力完美结合。它们共同简化了客户的物流并提高了透明度。