亮点

- At Greif, we have been incorporating recycled materials into our products for decades. Our Build to Last strategy demonstrates our commitment to being industry leaders in circularity.

- Advancing our product sustainability initiatives was a leading focus in 2024, particularly by creating opportunities to use post-consumer resin (PCR) and improving the recyclability of our plastic containers. Our innovative barrier coating technologies for plastic containers prevent the loss of our customers’ products while protecting the container from contamination.

- We create value for our customers by offering a broad suite of solutions that help them meet their sustainability goals.

- We continue to monitor the evolving regulatory landscape and are preparing to align our sustainability targets with new regulations as they emerge, including the EU’s Packaging and Packaging Waste Regulation (PPWR and Waste Framework Directive).

- In 2025, we expect to refine our sustainability targets based on an updated baseline, where circular manufacturing will play a key role in achieving our goals.

循环制造为何如此重要

Our Build to Last strategy and business model are rooted in circular economy principles. With our extensive expertise, legendary customer service, global reach, and diverse portfolio of solutions, we are uniquely positioned to deliver innovative, sustainable, and circular products and services. Circular manufacturing is central to our efforts to meet our customers’ needs today while preparing for the future as they navigate regulatory changes, shifting consumer trends, and ambitious sustainability goals. Advancing the circular economy is essential for our business growth, colleague engagement, talent attraction, and environmental impact.

Collaboration across value chains is critical to driving a circular economy. We strive to maximize waste diversion, material recovery, and value creation for our suppliers and customers. By promoting recycled content, collecting end-of-life containers, and forming strategic partnerships, we deliver sustainable solutions that drive mutual success. Reconditioning, recycling, and increasing recycled content throughout the product life cycle reduce resource consumption, minimize waste, and lower carbon emissions.

Our Approach

Our circular economy strategy emphasizes a cradle-to-cradle approach, advancing five key circular economy principles:

- 减少原始原材料的使用。

- 减少浪费并尽量减少自然资源的使用。

- 创新和提高可回收性以及使用再生材料。

- 一次性塑料的纤维替代品。

- Life cycle services including the collection, reconditioning, and recycling of used products.

Advancing circularity is a shared responsibility across our business and enabling functions. For example, our supply chain team integrates circularity objectives into key procurement categories like resin and steel, while sourcing managers explore innovative projects and new supply sources. These efforts embed circular principles into daily operations and help us achieve our 2030 circularity goals.

Reducing reliance on virgin raw materials is a cornerstone of our strategy. Lightweighting, downgauging, and prioritizing recycled materials are integral to our product design process. For instance, our EcoBalance product line incorporates up to 100 percent recycled high-density polyethylene sourced from post-consumer containers. Collaboration with customers and suppliers promotes the adoption of recycled and recyclable products, thereby aligning sustainability and business success.

We detail our approach and progress towards becoming a zero waste-to-landfill organization in the 浪费 本报告的部分。

Product Portfolio

We offer packaging solutions for essential industries, including agriculture, agrochemicals, specialty chemicals, food and beverage, pharmaceuticals, and more. Our solutions embrace circular economy principles:

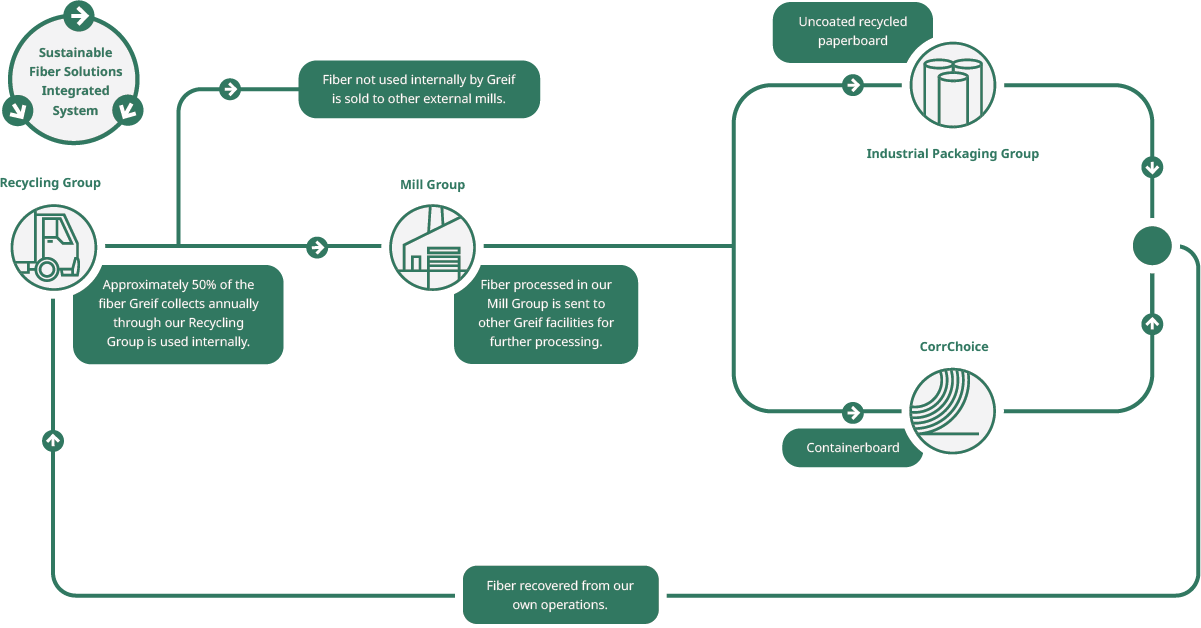

- Sustainable Fiber Solutions: Our vertically integrated solutions through the fiber packaging value chain demonstrate a circular economy. Our paper packaging solutions include fiber drums, tubes and cores, partitions, paperboard and containerboard, and corrugated products. We also develop products that replace single-use plastics with fiber-based alternatives. In 2024, 71 percent of all fiber products manufactured were sourced from recycled materials. Our Recycled Materials Group collected 3.4 million metric tons of fiber, of which 41 percent was then processed by Greif mills to produce paperboard for our paper packaging solutions.

Greif EnviroRAP

Greif EnviroRAP is 100 percent recycled paperboard with an innovative water-based, recyclable, and repulpable poly-alternative coating.

- Durable Metal Solutions: Steel drums are a sustainable packaging solution due to their infinite recyclability. They can even be reconditioned and reused multiple times before recycling. In 2024, our Life Cycle Services (LCS) network reconditioned and sold more than 1.2 million steel drums. We manufactured new steel products with approximately 5-30 percent recycled content, depending on the region.

- Customized Polymer Solutions: Our polymer solutions, including plastic drums, jerrycans, and intermediate bulk containers (IBCs) are lightweight, durable, and high performing. Our plastic packaging products are fully recyclable, supported by our comprehensive suite of barrier protection alternatives. Additionally, we reconditioned more than 1 million IBCs and 322,000 plastic drums.

生命周期服务

- Steel and Plastic: Our LCS network provides access to used steel, plastic, and paper products that reduce demand for virgin raw materials. In North America and Europe, we collect and recondition used steel, plastic, and IBC packaging products, making them suitable for reuse and resale. In 2024, our LCS network collected 3.6 million containers, reconditioned or remanufactured more than 2.6 million of these containers and recycled the remaining containers.

- Fiber: Greif’s Recycled Materials Group (RMG) serves as a commercial and industrial recycling partner, recycling all forms of paper and select plastics in the U.S. In 2024, RMG collected 3.4 million metric tons of material, with 41 percent used in our paper products and 59 percent sold to external mills. 86 percent of the fiber used in our paper manufacturing at our mills is sourced from recycled materials. We are a net positive recycler and a key player in the paper recycling industry.

Navigating Regulatory Landscapes

We proactively monitor evolving regulations related to circularity and waste. In 2024, we collaborated with trade associations and industry groups to stay informed, advocate for practical sustainability measures, and share insights. As new regulatory requirements emerge, we plan to refine our sustainability targets to ensure alignment. Circular manufacturing will remain central to achieving these targets.

Goals, Progress, & Performance

2030年目标:

- 使 Greif 产品 100% 可回收1.

- 我们的产品中再生原材料含量平均达到 60%2.

- 从市场回收的材料平均相当于我们运往市场的 80%3.

We have made significant strides towards achieving our 2030 goals, particularly within our Sustainable Fiber Solutions segment. Approximately 99 percent of our fiber solution products are recyclable and, on average, are made from 71 percent recycled content. Additionally, our RMG group collects 246% of the volume of fiber products that we sell.

We are tagging products appropriately across various systems to monitor recycled content and material recovery accurately as we progress toward our goals. In 2025, this process includes automating data collection and management activities to drive operational efficiencies and real-time data availability.

Across our Customized Polymer Solutions segment we are focused on a thorough review of sourcing, equipment, and technical capabilities to evaluate our capacity to increase PCR usage within our products.

We are working towards building a global network of material recovery solutions to reach our 2030 goals while growing our global reconditioning network. In November 2024, we acquired a majority stake in Delta Containers Manchester in the United Kingdom to expand and enhance our Intermediate Bulk Container (IBC) reconditioning and recycling services across the UK and Ireland. In December 2024, through our subsidiary Centurion Container LLC, we acquired the operations of Enterprize Container Corporation (“Enterprize”). Enterprize is an industrial reconditioner in Tennessee, U.S. that provides reconditioned and rebottled IBCs as well as reconditioned plastic drums.

通过涵盖广泛的原材料和产品组合,Greif 可回收性目标将以重量为基准,并在公司层面进行整合。

Greif 产品的再生材料含量目标是指公司层面合并的材料和产品组合中按重量计算的最低平均值。

[3] Greif 产品的回收目标是根据公司层面合并的一系列材料和产品重量得出的最低平均值。

在 IBC 成型中使用再生塑料

Greif 位于 Carol Stream 的 Tri-Sure 工厂与 RIPS 北美采购部、RIPS 意大利和四家 RIPS NA 工厂合作,采购了 800,000 磅再生塑料树脂,用于生产 IBC 后/角脚和护角。这种内部采购策略将成本降低了 $100,000。该团队还重新使用空瓦楞纸散装箱来运输他们制造的再生产品,将瓦楞纸散装箱的购买量减少了 84%。该项目创造了公司价值并建立了环境和财务效益,同时关闭了两个内部循环系统,并通过将垃圾从垃圾填埋场转移并为其找到新用途为我们的循环经济做出了贡献。由于该项目对可持续发展的突出影响及其可扩展到其他成型和注塑设施的能力,该项目和 Tri-Sure Carol Stream 团队荣获了 2019 年 Michael J. Gasser 可持续发展奖。

在葡萄牙修复锥形滚筒

For the past 20 years Greif’s RIPS facility in Iberia, Portugal has been supplying customers with reconditioned conical drums, having reconditioned over 10 million drums and saving 50,000 tons of steel, 197,600 tonnes of CO2 emissions, 2,600,000 gigajoules of energy and 343,200 cubic meters of water in the process. The project was initially started as a way to help address our customers’ wish to reduce waste and lower their carbon footprint and overall improve customer satisfaction. The team collaborated with customers to understand their needs, including volume, specification requirements and safety, developed a reconditioning process and ultimately installed a reconditioning line to begin serving customers. Today, the facility serves a multitude of customers, reconditioning 500,000 conical drums and saving 5,200 tons of steel each year.

通过投资和合资扩大从摇篮到摇篮的服务

In recent years, Greif has made investments and established multiple joint ventures in order to expand the scale and capabilities of the reuse, recycling, and reconditioning services we provide. After acquiring a minority stake in 2020, Greif has continued its investment in Centurion Container LLC, owning 80% of the company as of April 2023, to expand our intermediate bulk container (IBC) reconditioning network in North America. After beginning a joint venture with Delta Plastics, the leading independent supplier of reconditioned IBCs in the United Kingdom, in 2020, Greif completed full-acquisition in November of 2024. Additionally, in December of 2020, Greif acquired a minority stake in LAF s.r.l., expanding IBC reconditioning services for our Italy-based customers. We look forward to working with our partners to continue to reduce our environmental impact through cradle-to-cradle solutions.

里尔最先进的修复服务

Greif 位于法国里尔的 LCS 工厂已采取重大措施,革新与为客户提供修复服务相关的物流。传统上,空 IBC 会从单个客户所在的单一地点提货并运送到该地点。LCS Lille 已开始从客户供应链上的各个地点提货,然后将修复后的 IBC 送回客户,从而简化了客户的物流。里尔还实施了 Datamatrix,这是一种可追溯系统,使我们能够记录从接收到交付的所有生产步骤,了解 IBC 的来源,并实时查看我们的库存,以支持全面增强客户服务。Datamatrix 还支持更好地管理他们收集的 IBC 中的残留物。进入工厂的每个 IBC 都会自动称重,以确定容器中的残留物量并告知如何处理。借助 Datamatrix,这些信息可以直接发送回客户,以改善他们管理准备提货的 IBC 的方式。里尔采用闭环水系统来清洗IBC,并对其用水进行100%的回收利用,同时还收集、处理和粉碎用于制造新IBC和塑料桶的塑料。

为客户提供循环解决方案

The CorrChoice GreenGuard® CorrChoice GreenGuard® 产品系列为我们的客户提供食品安全、可回收和可再制浆的补充材料替代品,例如塑料衬里。我们的 GreenGuard® 系列纸张涂层可安全地与大多数食品类型直接接触,具有防油、防脂、防水、防潮和耐磨性,以及创新的蜡替代技术。通过将涂层应用于瓦楞纸容器,我们消除了许多食品应用中使用的补充材料的需求。我们与客户合作,确保我们的产品满足他们对安全可靠的食品处理的需求,同时提供 100% 可回收和可再制浆的包装产品,推进我们的循环经济战略,同时使我们的客户能够实现其可持续发展目标。

| 曲奇饼 | 期间 | 描述 |

|---|---|---|

| cookielawinfo-checkbox-分析 | 11个月 | 此 Cookie 由 GDPR Cookie Consent 插件设置。此 Cookie 用于存储用户对“分析”类别中 Cookie 的同意。 |

| cookielawinfo-checkbox-分析 | 11个月 | 此 Cookie 由 GDPR Cookie Consent 插件设置。此 Cookie 用于存储用户对“分析”类别中 Cookie 的同意。 |

| cookielawinfo-复选框功能 | 11个月 | 该 cookie 由 GDPR cookie 同意设置,用于记录用户对“功能性”类别中 cookie 的同意。 |

| cookielawinfo-复选框功能 | 11个月 | 该 cookie 由 GDPR cookie 同意设置,用于记录用户对“功能性”类别中 cookie 的同意。 |

| cookielawinfo-checkbox-必需 | 11个月 | 此 Cookie 由 GDPR Cookie Consent 插件设置。该 Cookie 用于存储用户对“必要”类别 Cookie 的同意。 |

| cookielawinfo-checkbox-必需 | 11个月 | 此 Cookie 由 GDPR Cookie Consent 插件设置。该 Cookie 用于存储用户对“必要”类别 Cookie 的同意。 |

| cookielawinfo-checkbox-其他 | 11个月 | 此 cookie 由 GDPR Cookie Consent 插件设置。此 cookie 用于存储用户对“其他”类别中 cookie 的同意。 |

| cookielawinfo-checkbox-其他 | 11个月 | 此 cookie 由 GDPR Cookie Consent 插件设置。此 cookie 用于存储用户对“其他”类别中 cookie 的同意。 |

| cookielawinfo-checkbox-性能 | 11个月 | 此 cookie 由 GDPR Cookie Consent 插件设置。此 cookie 用于存储用户对“性能”类别中 cookie 的同意。 |

| cookielawinfo-checkbox-性能 | 11个月 | 此 cookie 由 GDPR Cookie Consent 插件设置。此 cookie 用于存储用户对“性能”类别中 cookie 的同意。 |

| viewed_cookie_policy | 11个月 | 该 Cookie 由 GDPR Cookie Consent 插件设置,用于存储用户是否同意使用 Cookie。它不存储任何个人数据。 |

| viewed_cookie_policy | 11个月 | 该 Cookie 由 GDPR Cookie Consent 插件设置,用于存储用户是否同意使用 Cookie。它不存储任何个人数据。 |