精彩故事

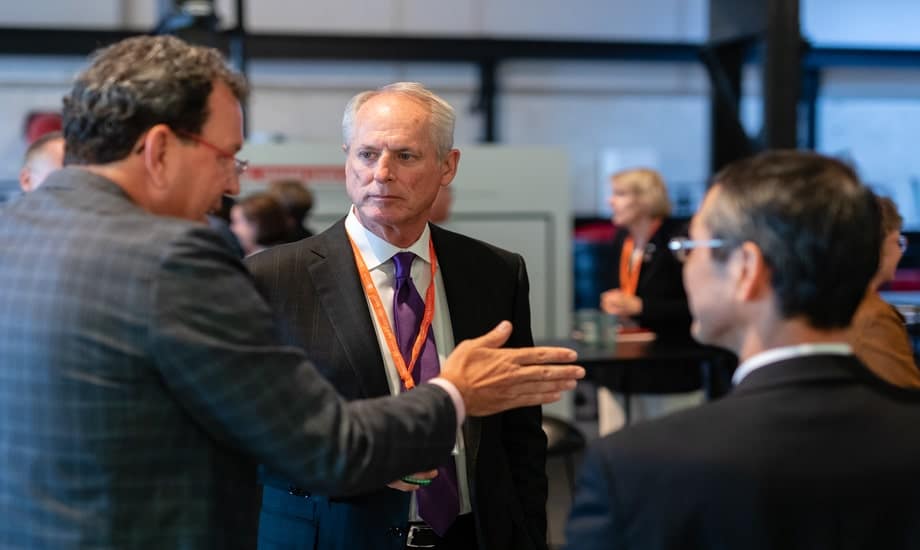

2019 年,Greif 位于比利时根特的 GIP 工厂采取措施进一步提高质量意识,举办了“质量日”,这是一个持续四小时的研讨会,专注于产品、工艺和客户服务的质量。共有 89 名同事参加,他们参加了特定的互动环节,旨在让参与者从不同的角度了解质量以及如何改进质量。许多同事报告说,他们更好地了解了自己对质量的具体贡献,并重新振作起来,积极提高整体客户满意度。

2014 年,我们的 CAR 数据显示,泄漏是客户最常见的质量投诉。为此,我们启动了一项零泄漏计划,以消除产品泄漏。收到泄漏投诉后,我们会上报给区域副总裁和总经理,我们的工程团队负责制定具体解决方案并将其分发给所有工厂。我们专注于减少泄漏,这使得泄漏投诉从 2014 年到 2018 年减少了 67%,并且 Tri-Sure 业务中的泄漏者数量也显著减少。

2020 年,我们成立了一个新的全球质量工作组,专门研究与产品质量相关的最突出的客户问题。我们的重点是分析外部和内部因素,以确定共同趋势。通过这种方式,我们发现我们最大的内部问题也与我们最大的外部问题相关。最大的客户问题仍然是产品完整性。该小组制定了各种行动计划,旨在解决这些内部问题,最终目标是减少我们最大的客户问题。我们制定了新的指标来跟踪这些计划的进展。

| 泄漏率 | 2019 财年 | 2020 财年 | 2021 财年 |

| 亚太地区 | 0.37 | 0.14 | 0.29 |

| 欧洲、中东和非洲 | 0.23 | 0.23 | 0.12 |

| 北美 | 0.22 | 0.22 | 0.16 |

| 拉美 | – | – | 0.07 |

在 COVID-19 疫情期间,Greif 位于马来西亚八打灵再也的全球工业包装工厂挺身而出,帮助客户解决了包装危机,展现了卓越的客户服务。Greif 的一位现有客户突然发现,他们无法从 Greif 的竞争对手那里获得运输食用油所需的无衬里群青桶。由于该工厂当时不提供该产品,八打灵再也团队迅速着手准备新的图稿,获得外部桶颜色批准,并创建新的产品库存单位。该团队立即开始生产并确保桶的运输,以满足客户的紧急需求。由于团队在应对这一紧急情况方面的反应迅速和独创性,客户继续向 Greif 订购该产品。

Greif 位于佐治亚州道尔顿的 PPS 回收工厂与当地地板制造厂密切合作,为管材和芯材提供回收服务,这是该行业产生的一大废物流。这些地板制造商也是 Greif 再生纸板管材和芯材的客户。当旧瓦楞纸板 (OCC) 的价格在 2019 年下跌时,以市场价格回收这些管材和芯材变得不经济。Greif 与地板制造商合作开发了一种可持续的循环解决方案,使废物不会进入垃圾填埋场,并使 Greif 能够继续为我们的客户提供优质的服务和 100% 再生纸板。在新的商业模式下,Greif 因管理可回收废物流而获得报酬,使我们能够加工这些材料,然后将其送到我们的造纸厂制造 100% 再生纸板。

![nouryon 的发音 nouryon [ zh ]](https://www.greif.com/wp-content/uploads/2022/04/hs_nouryon.png.png)

Greif 的长期健康和安全目标是实现全球所有工厂零事故。虽然我们认识到这一目标的挑战,但我们的 10 个全球工业包装 (GIP) 工厂(包括以下工厂)已实现 10 年或更长时间的无事故运营:

主席安全卓越奖

每家实现 MCR 为零的工厂都将获得董事长安全卓越奖。2023 年,我们在全球范围内有 97 家生产工厂获得了该奖项,并在虚拟颁奖典礼上获得表彰。

包容性领导力培训

包容性领导力之旅旨在让 Greif 的人力资源经理和高级领导了解包容性领导力。该计划涵盖包容性领导力的基础,帮助全球领导者在工作场所发展和展现包容性行为。培训深入定义和讨论无意识和隐性偏见的影响、包容性的最佳实践和可行步骤,并研究包容性的影响。学习之旅包括对每位参与者当前包容性行为水平的保密评估,以及实施关键主题的个性化行动计划。课程于 2021 年 10 月开始,将持续到 2022 年 4 月。

拉丁美洲多元化周

在 Greif,我们鼓励并接受文化、语言、地点和思想的多样性。2021 年 8 月 9 日至 13 日这一周,拉丁美洲人力资源团队举办了多元化周活动,以教育我们的同事尊重他人和践行 Greif 之道的重要性。为期一周的活动包括虚拟学习课程,涵盖无意识偏见、性别、女性与职业、世代、LGBTQIA+ 和出身/种族多样性等主题。总共有 700 多名同事参加了活动。

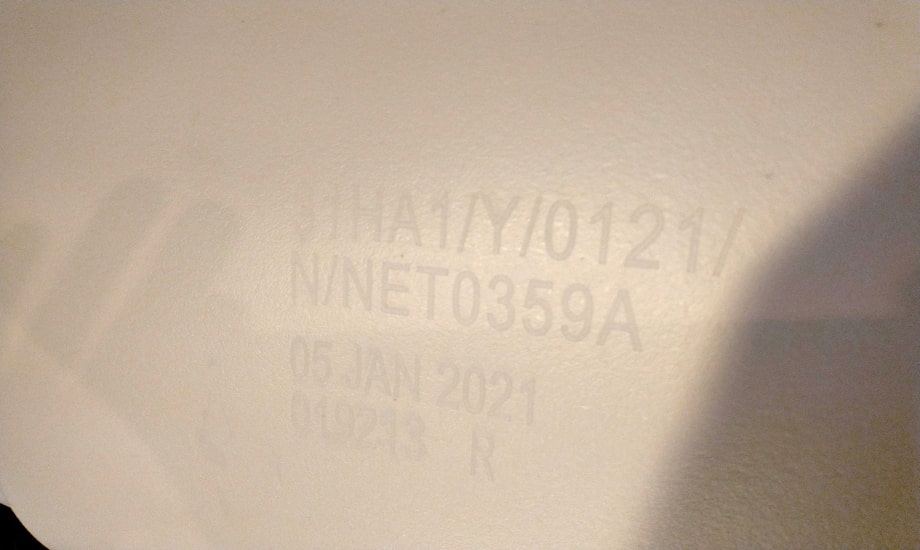

IBC 上的激光标记

Greif Sweden/Nordic 是市场上第一家在中型散装容器 (IBC) 上用激光标记取代喷墨标记的公司,从而减少了生产过程中溶剂型油墨的使用。通过消除溶剂和油墨的使用,生产环境更加清洁。我们还能够通过移除传统上用于激光标记的板材,将 IBC 的重量减轻一公斤。我们相信这项创新将为 IBC 上的标记树立新的标准。

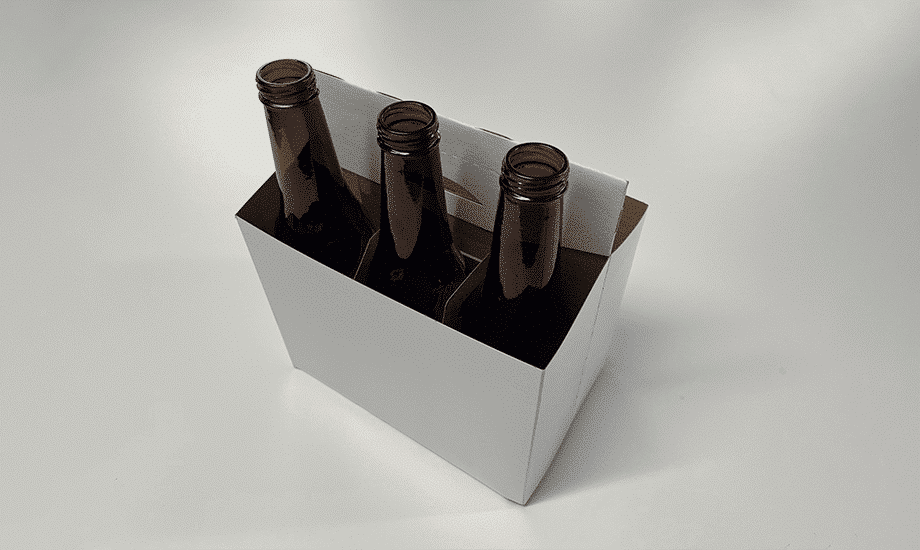

适用于偏远地区的击倒鼓 (KDD)

格雷夫 击倒鼓 (KDD) 为将钢桶运输到偏远地区提供最佳的可持续解决方案。半成品钢桶部件在现场运输和组装,所需人员和设备最少。独特的概念允许在 20 英尺海运集装箱中运输多达 1,176 个 KDD,而完整的成品钢桶则为 80 个,从而节省了宝贵的空间,优化了运输成本,并在较长的运输时间内最大限度地减少了客户的碳足迹。钢桶直接运送到客户的加油站,有助于提高效率,减少库存和人工处理。

- RIPS 伊利诺伊州内珀维尔: 100%

- 德国门迪希(RIPS Mendig): 98%

- 德国科隆RIPS: 98%

- RIPS 伊利诺伊州洛克波特: 98%

- 土耳其苏丹贝利FPS: 98%

- 荷兰RIPS Europoort: 97%

- 德国阿滕多恩 RIPS 电视台: 96%

- 捷克共和国乌斯季 RIPS: 95%

- 阿根廷坎帕纳的RIPS: 83%

- RIPS上海,中国: 80%