亮点

- 我们通过制造、修复、再利用和回收流程积极管理包装的生命周期,因为循环经济原则是我们“持久耐用”战略的重要组成部分。

- Greif 的生命周期服务网络收集使用过的和空的钢制、塑料和中型散装容器硬质包装产品,并对其进行修复或回收,从而积极减少对原材料的需求和送往垃圾填埋场的容器数量。

- 我们的 2030 年目标旨在使所有 Greif 产品都可回收利用、增加我们产品中的可回收原材料以及从市场上回收更高比例的材料。

循环制造为何如此重要

坚持和推进循环经济原则是 Greif 的“持久耐用战略”和客户合作伙伴关系的重要组成部分。我们通过制造、修复、再利用和回收流程积极管理包装的生命周期。创造体现循环性并建立在环境和社会资本基础上的产品需要与我们的供应商、客户和其他价值链合作伙伴合作。废物转移和材料回收加强了我们的循环经济管理,并使我们能够与供应商建立更牢固的关系。在我们的价值链上进行协作和建立伙伴关系有助于我们开发可持续和创新的解决方案,以推进我们的共同目标,减少环境影响,为产品提供更可持续的报废方式,并推进我们的企业和可持续发展目标。

治理

我们在整个运营和价值链中实施的循环经济战略不仅限于使用再生产品,我们还考虑采用从摇篮到摇篮的方法。作为该战略的一部分,我们致力于在五个关键领域推动循环经济原则:

- 减少原材料的使用

- 减少废物和减少自然资源的使用

- 创新并提高产品的可回收性,并使用再生材料

- 一次性塑料的纤维替代品

- 生命周期服务

我们通过增加回收材料的使用以及减轻产品重量和减少产品厚度来减少原始原材料的使用。减轻产品重量和减少产品厚度可减少对原材料的依赖,并防止新原材料进入我们的价值链。例如,Greif Latin America 开发了一种大型塑料桶,采用多面侧壁方法,可去除桶中高达 14% 的树脂,同时保持性能。多面桶通过减少自然资源消耗、降低基于化石燃料的原材料使用量和二氧化碳排放量来支持我们的循环经济和脱碳战略2 运输过程中的排放。

我们将继续设计和开发可回收且由再生材料制成的产品,努力实现 100% Greif 产品可回收的目标1 实现产品中再生原材料含量平均达到 60%2通过使用再生材料和制造可回收产品,材料在我们的价值链中仍然有用。我们与客户和供应商合作,提高再生和可回收产品的可用性和使用率。我们的 EcoBalance 产品线使用高达 75% 的从消费后容器中获得的再生高密度聚乙烯制成,我们的纸质包装和服务 (PPS) 产品按体积计算可回收率达 99%。

EcoBalance™ IBC 降低碳排放

Greif 通过其配备消费后树脂 (PCR) 和闭环回收服务的可持续 GCUBE 中型散货容器 (IBC) 支持德国油漆生产商 Schulz 大幅减少其碳足迹。

Greif 的 GCUBE IBC 配备 PCR,由 60% 的纯 PE 和 40% 的 PCR 组成。为了保证产品完整性,IBC 瓶的内层仍为 100% 纯高密度,而外层主要由 PCR 制成。此外,大多数外部组件(如护角、塑料脚和塑料托盘)均采用再生聚乙烯制成。PCR 是由收集的空 IBC 生成的,然后在 Greif 位于门迪格的修复和回收设施中进行处理。

Schulz 多年来一直使用标准 IBC,并一直在寻找减少其对环境影响的新方法。“改用带有 PCR 的 GCUBE IBC 帮助我们实现了可持续发展目标,减少了原材料消耗并减少了二氧化碳2 舒尔茨的一位发言人解释道。

带有 PCR 的 GCUBE IBC 扩展了 EcoBalance™ 产品线,包括使用 PCR 制造的桶和其他运输容器。EcoBalance™ 产品线有助于支持 Greif 的客户实现其可持续发展目标,包括减少碳排放和能源消耗以及将垃圾从垃圾填埋场转移。EcoBalance™ 产品线有助于支持 Greif 的客户实现其可持续发展目标,包括减少碳排放和能源消耗以及将垃圾从垃圾填埋场转移。

Greif 遍布北美和欧洲的生命周期服务 (LCS) 网络收集使用过的和空的钢、塑料和中型散装容器 (IBC) 硬质包装产品以及回收的纤维,并对其进行修复或回收,使其适合重复使用和转售。这项工作积极减少了对原材料的需求,并减少了送往垃圾填埋场的容器数量。在我们的全球工业包装 (GIP) 业务中,我们在 2022 年修复、再制造或回收了超过 270 万个容器。我们的 PPS 业务在 2022 年管理了超过 330 万公吨的再生纤维。请参阅 创新 请参阅本报告的部分以了解更多信息。

我们的目标是帮助我们的客户及其客户安全、经济且环保地收集符合条件的旧包装。作为该网络的一部分,客户可以通过 Greif Green Tool 和 Green Tool Lite 接收报告,从而通过跟踪碳足迹减少、废物减少和材料节省等关键指标来量化影响。有关我们的循环制造工作及其对水、废物和排放的影响的更多信息,请参阅本报告的 创新, 浪费 和 水 部分。

纸包装与服务

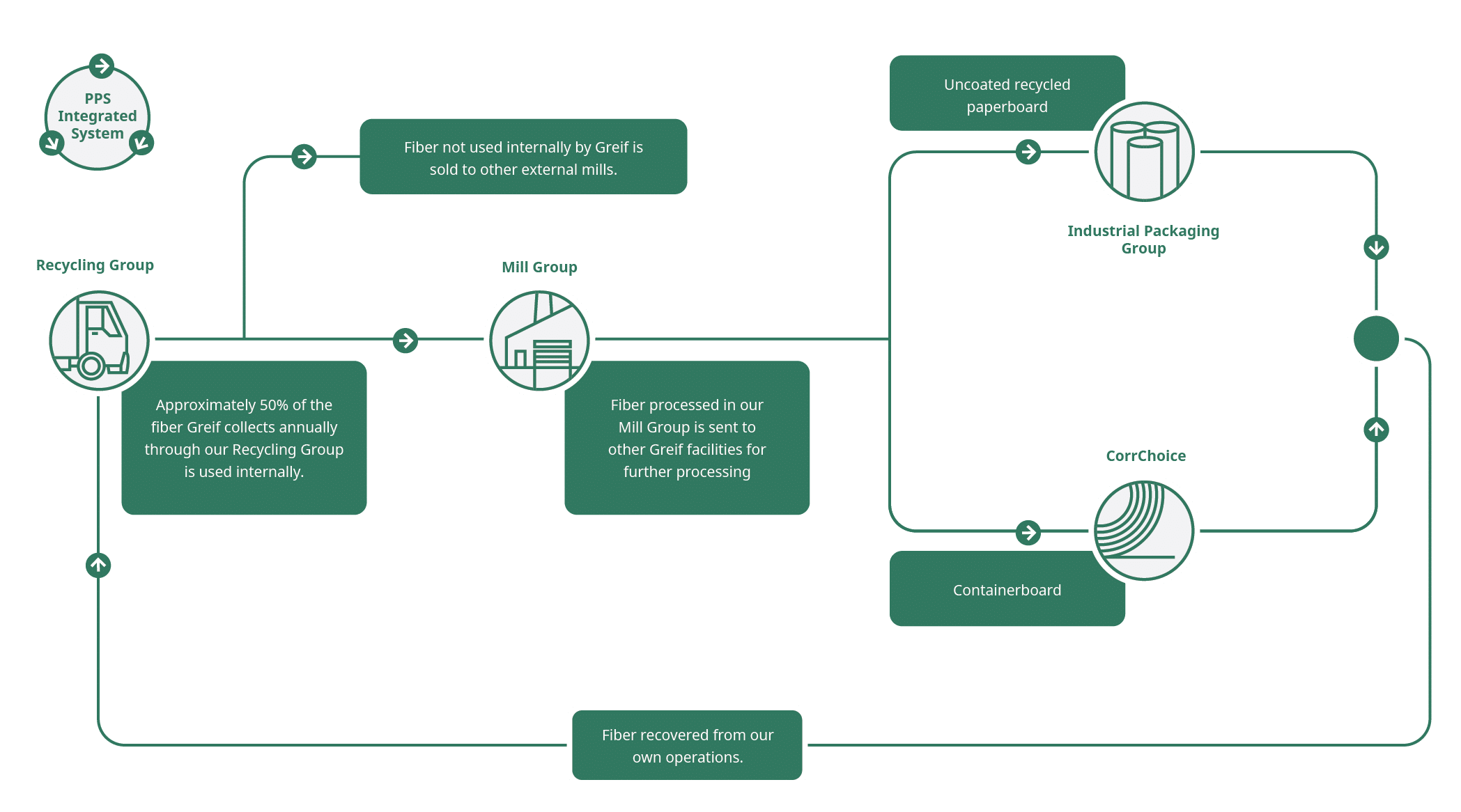

Greif 在我们的 PPS 业务中运营 19 个回收设施。我们的设施提供塑料、纸浆和纸纤维采购、运输和管理的完整外包解决方案,并提供完整的纸纤维审计和管理解决方案。按体积计算,我们的回收业务处理的 99.2% 的产品是纸纤维。我们的纸纤维回收业务收集废纸,供我们的箱板纸厂使用,并出售给其他箱板纸和再生纸产品制造商。我们在运营中收集的纤维中约有 50% 用于制造消费和工业环境中的纸制品。我们收集剩余 50% 的纤维出售给外部工厂和其他制造业务,以生产新纸板、模制纤维包装和其他产品。我们在造纸中使用的纤维中有 78% 以上来自回收投入。由于我们的综合能力,Greif 是一家净正回收商,巩固了我们作为纸张回收行业重要代表的地位。

回收纤维是许多必需品的投入。在 COVID-19 之前,回收纤维的价值处于历史低位,许多回收商的回收成本高于纤维价值。在 2020 年 COVID-19 爆发之初,回收纤维的供应落后于需求,导致纤维稀缺和成本持续高企。然而,在 2022 年底,纤维市场经历了几十年来未曾经历过的转变,导致再生纤维的价格往往低于新纤维。由于这一前所未有的转变,我们现在专注于重新教育客户再生纤维的优势。我们的参与努力和行业团体的参与将有助于教育市场了解不断变化的行业动态,确保依赖回收纤维投入的商品仍然是具有强大供应链的可行企业。

EasyPour 混凝土成型管

Greif 的高品质 100% 再生纸板混凝土成型管可为要求严格的混凝土项目提供卓越的性能,包括柱子、基础、桥墩和其他结构。EasyPour 管是我们努力将新产品线商业化的一个例子,这些产品线用再生材料产品取代原生产品,并通过加入我们的水性阻隔涂层来去除塑料。EasyPour 管还为我们的客户提供具有改进的报废解决方案的产品,从而推进我们的循环经济战略。EasyPour 的内置防风雨技术提供防潮性并提高强度和耐用性。EasyPour 管符合 LEED® 标准,由 Greif 工厂生产的 100% 再生纸板制成,完全可回收和再制浆。过去,我们在制造建筑管时使用聚乙烯衬里。

2021 年和 2022 年,我们利用纸张创造了一种可回收材料替代品。开发这种替代品是减少塑料垃圾的重要一步。

全球工业包装

我们的 GIP 业务尽可能寻找再利用和回收机会。平均而言,我们的塑料产品中 90% 以上都是可回收的,我们内部研磨的塑料(按重量计算,约占我们桶和 IBC 的 20%)被 100% 重新用于我们的产品中。我们根据地区不同,使用约 5% 至 35% 的回收钢材来制造我们的钢铁产品。

目标、进展与表现

我们的 LCS 网络覆盖的钢铁、塑料和纸制品数量众多,这对 Greif 来说是一笔巨大的财富。2022 年,一个跨职能团队确定了 Greif 的全球循环目标,并将其传达给市场。Greif 目前正在组建实现每个业务部门这些目标所需的团队。2023 年,我们计划实现 2030 年目标的数据收集自动化,建立循环团队来监督我们最重要的循环工作流程,并制定主要行动项目和高级路线图,以帮助我们实现 2030 年目标。

2030年目标:

- 使 Greif 产品 100% 可回收1.

- 我们的产品中再生原材料含量平均达到 60%2.

- 从市场回收的材料平均相当于我们运往市场的 80%3.

Greif 产品的再生材料含量目标是指公司层面合并的材料和产品组合中按重量计算的最低平均值。

[3] Greif 产品的回收目标是根据公司层面合并的一系列材料和产品重量得出的最低平均值。

在 IBC 成型中使用再生塑料

Greif 位于 Carol Stream 的 Tri-Sure 工厂与 RIPS 北美采购部、RIPS 意大利和四家 RIPS NA 工厂合作,采购了 800,000 磅再生塑料树脂,用于生产 IBC 后/角脚和护角。这种内部采购策略将成本降低了 $100,000。该团队还重新使用空瓦楞纸散装箱来运输他们制造的再生产品,将瓦楞纸散装箱的购买量减少了 84%。该项目创造了公司价值并建立了环境和财务效益,同时关闭了两个内部循环系统,并通过将垃圾从垃圾填埋场转移并为其找到新用途为我们的循环经济做出了贡献。由于该项目对可持续发展的突出影响及其可扩展到其他成型和注塑设施的能力,该项目和 Tri-Sure Carol Stream 团队荣获了 2019 年 Michael J. Gasser 可持续发展奖。

地板行业的纤维回收

2020 年,我们位于佐治亚州道尔顿的回收工厂与道尔顿地区的地板覆盖物制造商合作,加工回收的纤维,并为纸板芯创建“闭环”。每年,道尔顿回收团队都会从这些制造商那里回收数万吨芯废料,并回收这些废纤维。Greif 的造纸厂使用同样的纤维制造 100% 回收的新纸板,然后在 Greif 的工业产品集团 (IPG) 将其转化为新的管和芯。这项举措不仅有助于维持道尔顿的回收计划,而且还能保持我们为 IPG 客户提供的卓越客户服务水平。每年,该计划有助于回收北乔治亚州地板行业的 25,000 吨芯、10,000 吨纸板、5,000 吨箱板和 2,000 吨塑料薄膜。

在葡萄牙修复锥形滚筒

过去 20 年来,Greif 位于葡萄牙伊比利亚的 RIPS 工厂一直为客户提供翻新的锥形滚筒,已翻新了超过 1000 万个滚筒,节省了 50,000 吨钢材、197,600 吨二氧化碳排放量、2,600,000 千兆焦耳的能源和 343,200 立方米的水。该项目最初是为了帮助满足客户减少浪费、降低碳足迹和全面提高客户满意度的愿望而启动的。该团队与客户合作,了解他们的需求,包括数量、规格要求和安全性,开发了翻新工艺,并最终安装了一条翻新生产线,开始为客户提供服务。如今,该工厂为众多客户提供服务,每年翻新 500,000 个锥形滚筒,节省 5,200 吨钢材。

通过投资和合资扩大从摇篮到摇篮的服务

2020 年,Greif 进行了投资并成立了多家合资企业,以扩大我们提供的再利用、回收和修复服务的规模和能力。4 月,Greif 收购了 Centurion Container LLC 的少数股权,扩大了我们在北美的中型散货容器 (IBC) 修复网络。8 月,Greif 与英国领先的修复 IBC 独立供应商 Delta Plastics 成立了合资企业。最后,在 12 月,Greif 收购了 LAF srl 的少数股权,扩大了我们为意大利客户提供的 IBC 修复服务。我们期待与合作伙伴合作,继续通过从摇篮到摇篮的解决方案减少对环境的影响。

里尔最先进的修复服务

Greif 位于法国里尔的 LCS 工厂已采取重大措施,革新与为客户提供修复服务相关的物流。传统上,空 IBC 会从单个客户所在的单一地点提货并运送到该地点。LCS Lille 已开始从客户供应链上的各个地点提货,然后将修复后的 IBC 送回客户,从而简化了客户的物流。里尔还实施了 Datamatrix,这是一种可追溯系统,使我们能够记录从接收到交付的所有生产步骤,了解 IBC 的来源,并实时查看我们的库存,以支持全面增强客户服务。Datamatrix 还支持更好地管理他们收集的 IBC 中的残留物。进入工厂的每个 IBC 都会自动称重,以确定容器中的残留物量并告知如何处理。借助 Datamatrix,这些信息可以直接发送回客户,以改善他们管理准备提货的 IBC 的方式。里尔采用闭环水系统来清洗IBC,并对其用水进行100%的回收利用,同时还收集、处理和粉碎用于制造新IBC和塑料桶的塑料。

为客户提供循环解决方案

CorrChoice GreenGuard® 产品系列为我们的客户提供食品安全、可回收和可再制浆的补充材料替代品,例如塑料衬里。我们的 GreenGuard® 系列纸张涂层可安全地与大多数食品类型直接接触,具有防油、防脂、防水、防潮和耐磨性,以及创新的蜡替代技术。通过将涂层应用于瓦楞纸容器,我们消除了许多食品应用中使用的补充材料的需求。我们与客户合作,确保我们的产品满足他们对安全可靠的食品处理的需求,同时提供 100% 可回收和可再制浆的包装产品,推进我们的循环经济战略,同时使我们的客户能够实现其可持续发展目标。