SUSTAINABILITY STRATEGIES

Committed to using financial, natural and human resources wisely without compromising the ability of future generations to meet their needs

Reducing Our Footprint

As a global manufacturer, it is our obligation to understand and work to minimize our environmental impact. Whether in our operations or along our supply chain, our sustainability agenda works to create sustainable value for our customers, the environment and Greif stakeholders.

changing world.

Why Climate Strategy Maters

Governance

We integrate energy efficiency throughout the organization. Energy efficiency is a consideration in capital deployment. All Greif colleagues are eligible for awards and recognition related to energy reduction. Since 2010 Greif has maintained a Global Energy Team, currently consisting of more than 20 members, that is responsible for coordinating energy and emissions reduction projects throughout the company. In 2019, we restructured the team to place an increased emphasis on including regional leadership to better engage and identify energy opportunities within each business unit and legacy Caraustar facilities. This change in structure has streamlined our energy roadmap process, allowing us to focus on and invest in the business units and facilities that have the most impactful energy opportunities.

Whereas previously each facility was responsible for developing their own roadmap, regional leadership is now responsible for collaborating with each business unit to identify energy reduction and efficiency opportunities. Four of our production facilities have achieved ISO 50001 certification for energy management.

In 2020 we implemented 73 energy efficiency projects, resulting in $724,419 of savings across our organization. These projects include replacing equipment and updating processes that reduce energy demand, such as replacing ovens, boilers and adjusting water temperatures and implementing energy efficiency practices, such as lighting and HVAC replacements. For more information about our energy efficiency projects, please see section C4.2 and C4.3b of our 2020 CDP Climate Response.

A focus in 2020 was fully integrating legacy Caraustar facilities into our energy and emissions reporting. Our legacy Caraustar facilities now account for approximately 45 percent of our energy consumption and emissions impact globally, which has changed the scale of our impact and led us to adopt new mitigation activities appropriate for our business.

In 2020, we began taking steps to better understand our broader climate impact and align to the Task Force on Climate-related Financial Disclosure (TCFD) recommendations. To begin this process, we conducted a gap analysis of our current climate management practices against TCFD recommendations to identify priority areas of focus to advance our climate strategy and modeled potential climate targets under multiple temperature scenarios. This work led to the identification and approval of our new 2030 emissions target and revealed a need to conduct a more detailed scenario analysis to better understand both our transitional and physical climate-related risks and opportunities. Our currently identified climate-related risks and opportunities are summarized below and discussed in further detail in our CDP response. In 2021 we will conduct a scenario analysis intended to deepen our understanding of these risks and opportunities, validate if they are the most material climate-related risks and opportunities and uncover additional potentially material climate-related risks and opportunities that should inform our overall climate strategy. As we conduct this work, we are pleased to include our first TCFD index in this year’s report, demonstrating our current areas of alignment with TCFD recommendations. We are looking forward to building on this progress in 2021.

| RISK/OPPORTUNITY | TOPIC | DESCRIPTION* |

|---|---|---|

| Risk | Impacts to production capacity | Climate change, to the extent it produces rising temperatures inducing sea level rise, may adversely impact our ability to manufacture and transport our products. Our operations include facilities in low-lying coastal areas such as Europoort, Vreeland, and Asterweg, in the Netherlands; Malaysia; and Singapore, all which may be significantly impacted by sea level rise. |

| Risk | Impacts to indirect (operating) costs | Climate change, to the extent it impacts the price of our raw materials, fuel, transportation, and natural gas costs impacts our production and raw material supply costs. Impacts may be caused by increased regulation, changing market conditions, and impacts on our supply chain. |

| Risk | Impacts to revenues due to reduced production capacity | Climate change, to the extent it impacts the frequency and severity of precipitation extremes and related natural disasters— including wildfires and flooding—may impact our ability to manufacture and transport our products. Such climate-related extremes may impact our footprint in any geography at any time. |

| Opportunity | Development and/or expansion of low emission goods and services | Greif works with our raw material suppliers, transportation partners, and internal teams to develop lighter weight and more energy efficient products and provide transportation and ancillary services to help our customers reduce emissions associated with our packaging (e.g. EcoBalance, NexDRUM®). Our engagement with customers through “Voice of the Customer” interviews and surveys, materiality assessment interviews, and other avenues, confirms that our customers have a desire for low emission products. |

| Opportunity | Shift in consumer preferences | As corporations, investors, and the general public become increasingly attuned to climate change issues, industrial manufacturing clients are at risk of changing public perceptions around a company’s operations and product lines. By developing products and services that decrease customers' GHG emissions and waste in their value chain Greif can set itself apart from competitors, garner market share and reinforce its positive reputation. |

| Opportunity | Use of more efficient production and distribution processes | Due to potential changes in legislation/regulation, we could incur increased energy, environmental and other costs and capital expenditures to comply. However, this also affords us the opportunity to further improve our energy efficiency, thereby reducing our costs and exposure to these risks. |

*Please see Greif’s 2020 CDP Climate Change Response for additional information.

Goals & Progress

2020 marked the end of our current energy and greenhouse gas goal, but not the end of our commitment to reduce our environmental impact. In 2020, we conducted a detailed analysis and evaluation with a third party of our ability to commit to a goal that would be approved by the Science Based Target Initiative (SBTi). We are excited to announce our commitment to reduce our Scope 1 and Scope 2 emissions by 28 percent by 2030, from a 2019 baseline. This new target is aligned with prevailing climate science to limit overall global warming to well below 2 degrees Celsius and builds upon the company’s 11 percent emissions reduction per unit of production accomplishment achieved in 2020. By the end of 2023, Greif will also complete an assessment of its Scope 3 emissions and determine the feasibility of a long-term net zero emissions aspiration in alignment with the Science-based Targets Initiative.

To achieve our new target, we will build upon our existing investments in energy efficient equipment, onsite solar power, and grid-sourced green electricity with a strategic approach that will include additional energy efficiency initiatives and sourcing of offsite, large-scale renewable energy.

2020 Goal: 10 percent reduction in energy and greenhouse gas (GHG) emissions per unit of production, from a fiscal 2014 baseline.

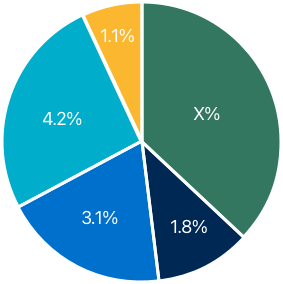

Progress: As of the end of fiscal 2020, we achieved an 11 percent emissions reduction per unit of production decrease from a fiscal 2014 baseline and 1.1 percent reduction in energy consumption per unit of production from the 2014 baseline.

2030 Goal: Reduce absolute Scope 1 and Scope 2 GHG emissions 28 percent over a 2019 baseline. Greif will also complete an assessment of Scope 3 emissions and determine the feasibility of a long-term net zero emissions aspiration by the end of 2023.

Performance

Reduction in Energy per Unit of Production per Year

KEY:

- 2014

- 2016

- 2017

- 2018

- 2020

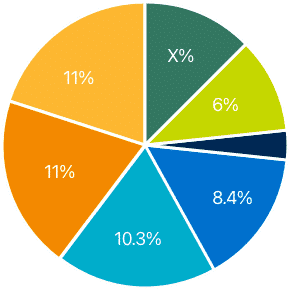

Reduction in Emissions per Unit of Production per Year**

KEY:

- 2014

- 2015

- 2016

- 2017

- 2018

- 2019

- 2020

GHG Emissions (Metric Tons)

| FY 2014* | FY 2015 | FY 2016 | FY 2017 | FY 2018 | FY 2019 | FY 2020 | |

|---|---|---|---|---|---|---|---|

| Total Energy Consumption (MWh) | 3.2 Million | 3 Million | 3 Million | 3 Million | 3.1 Million | 5.3 Million | 5.4 Million |

| Scope 1 | 362,300 | 322,500 | 345,700 | 367,700 | 376,700 | 675,900 | 692,900 |

| Scope 2 Location Based |

496,000 | 438,600 | 446,700 | 416,000 | 415,900 | 637,300^ | 589,500 |

| Scope 3 | 251,500 | 221,900 | 2,927,000 | 3,089,000 | 2,867,090 | 4,403,000 | 4,148,000 |

| TOTAL | 1,109,800 | 983,000 | 3,719,400 | 3,872,700 | 3,659,600 | 5,716,200^ | 5,430,400 |

NOTES:

- Source: Greif 2020 CDP Climate Response

- Energy and emissions data accounts for all legacy Greif and Caraustar facilities from 2019 forward.

- Emissions data accounts for CO2, CH4 and N2O.

- Scope 3 emissions takes into account upstream transportation and distribution. In 2017, scope 3 was expanded to include purchased goods and services, capital goods, fuel and energy related activities not included in Scope 1 and 2, including waste generated in operations, business travel, employee commuting and end of life treatment of sold products. Data based on legacy Greif Facilities only.

- 2020 GHG Verification Statement

Transitioning to Electric Forklifts

As part of our overarching goal of having more efficient and sustainable equipment, in 2018 we began transitioning our fleet of forklifts from being powered by combustion gasoline to electricity, which reduces our forklift emissions approximately 50 percent. Through 2020, we have converted 99 percent of our forklifts in EMEA to electricity power while we reduced fleet size by 17 percent and realized a cost savings of $352,000 in 2020. In North America, we have replaced 2 percent of our fleet and saved $250,000 in 2020. Due to the success of the program, and in support of our overall Renewable Forklift Policy, the program will continue to be rolled out globally. In addition to the environmental benefits, the transition provides a safer working environment for our colleagues by reducing the need to keep containers of gasoline in our facilities.

Transitioning to Electric Forklifts

As part of our overarching goal of having more efficient and sustainable equipment, in 2018 we began transitioning our fleet of forklifts from being powered by combustion gasoline to electricity, which reduces our forklift emissions approximately 50 percent. Through 2020, we have converted 99 percent of our forklifts in EMEA to electricity power while we reduced fleet size by 17 percent and realized a cost savings of $352,000 in 2020. In North America, we have replaced 2 percent of our fleet and saved $250,000 in 2020. Due to the success of the program, and in support of our overall Renewable Forklift Policy, the program will continue to be rolled out globally. In addition to the environmental benefits, the transition provides a safer working environment for our colleagues by reducing the need to keep containers of gasoline in our facilities.