Why Customer Service Excellence Matters

Governance

90

Customer Service Excellence Award Winners

Honoring our facilities that demonstrated best-in-class customer service performance throughout 2021.

The Greif Global Commercial Excellence (ComEx) Team, led by our Chief Administrative Officer (CAO), manages our customer service practices and policies. The ComEx Team is comprised of our CAO and leaders from each of our business segments. The team meets monthly to share best practices, improve communications, drive processes and engage cross-functional leaders. Our Human Resources department is responsible for developing trainings to bolster our colleagues’ skills and behaviors related to providing exceptional customer service. The ComEx Team decides on key actions and the departmental teams work to implement them. The team is also responsible for tracking progress on the Customer Satisfaction Index (CSI) and Net Promoter Score (NPS)—our measures of customer satisfaction and likelihood of a customer recommending Greif to others.

Our ComEx Team is structured to allow us to better organize around the key markets that Greif serves, ultimately improving our ability to address each customer’s unique needs. Every Greif colleague supports our customer service efforts by advancing our operational excellence through everyday behaviors.

We measure every plant using our CSI, which tracks various indicators, including complaints, delivery times and customer response times. Managers review the index monthly during performance reviews. When conducting our annual performance reviews, we also look at NPS. The combination of these two measures allows us to gauge where we stand on CSE and provides us insight into areas we can improve. In 2021, the Mill Group reduced the number of customer complaints by 30% which resulted in a reduction of customer claims by over $2 million.

Every Greif professional colleague receives CSE training. During this training, these colleagues focus on developing seven CSE skills. As each colleague advances in the program, peers provide feedback to each other, reinforcing learning on a daily basis and helping to instill the customer service culture we are working to achieve. We offer the CSE training in 19 languages, through a blended, facilitated and online program as well as fully online modules. We use this training to provide all professional colleagues with the necessary skills and tools to provide the best service possible to both internal and external customers. We require all new hires to complete the training via online modules. We also offer additional voluntary CSE training through Greif University. We will continue developing CSE training for our manufacturing colleagues, building on the success and learnings of the professional colleagues’ program, in 2022.

This year we implemented new tools to improve our efficiency in responding to customer needs and overall customer experience. We began utilizing a global system to prepare offers to customers. This system allows us to improve our consistency in pricing and improves our customer response time. We also began using a cloud-based sales enablement platform that helps our sales and marketing teams have more consistent messaging. It also allows our sales team to find and share information more quickly. To further improve the customer experience, we will begin developing an online customer platform to improve our communication and the way we serve customers in 2022.

Across Greif, we view feedback collected from our NPS survey as an opportunity to address our customers’ concerns and provide corrective actions when necessary. After each NPS survey, we connect with all respondents and focus on engaging each survey detractor – a customer that rates Greif poorly – to understand their perspective and create improvement plans addressing their concerns. As a result of these engagements, we are focusing on improving our communication with our customers by proactively engaging them, so colleagues have the time to respond to communications appropriately – one of the seven skills we are teaching our colleagues through training. We continue to leverage the increased customer interactions that accompany each survey into enhanced service offerings for our customers and better strategic insight into their business needs.

In 2020, we conducted a Voice of the Customer (VOC) project engaging over 600 Greif customers through interviews and surveys. Through these engagements, we worked to determine each customer’s top priorities, how these priorities impact their decision-making and determine what our customers are looking for in a strong partnership. Our customers shared the importance of speed and responsiveness to requests and issue resolution and communication. Understanding our customers’ top priorities enables us to define our own organizational priorities and guides our decision-making. In response to these learnings, we are working on improving the customer experience through digitalization and developing work streams to solve the internal pain points to better respond to customer requests. Our IBC collections app, a digital tool used for customers to submit requests for Greif to pick up their discarded packaging products, is an innovation that we developed from VOC project feedback.

One of the learnings from the VOC project was a clear need for sustainable products. In response, we added sustainability performance indicators focused on meeting with customers, identifying clear objectives and setting post-consumer resin (PCR) product targets for each facility that produces PCR in 2021. The Global Industrial Packaging Leadership Team tracks these sustainability performance indicators monthly. We are also training additional colleagues in EMEA and APAC as well as our sales force on how to support our customers’ sustainability targets, and the Greif Green Tool, a tool designed to assist our customers in making informed decisions about which industrial packaging best fits their needs and helps them to achieve their sustainability goals.

In 2021, we began conducting in-depth market research to identify business growth opportunities and to be a better resource for our customers. We identified fast-growing industries and engaged with customers to analyze key trends in the industry and how the trends may impact packaging needs. The information gathered from these analyses allows us to tailor our products and sales approach to align with market trends. We also developed an industry council focused on critical industries. At least quarterly, we bring together Greif’s subject matter experts from across the globe to discuss challenges, solutions and opportunities and share general industry knowledge and trends to encourage growth.

We are evaluating the quality of our sales visits through analysis and coaching sessions by sales leaders. Our sales account managers are more prepared than ever to address our customers’ needs and provide quality visits with our customers. To ensure the health and safety of our colleagues and customers during the COVID-19 pandemic, we offered a series of webinars and virtual plant tours. Our webinars covered topics such as sustainability, product deep dives and innovation. Through this virtual approach, we were able to conduct more plant visits than prior years. Over the past two years we hosted more than 20 webinars attended by more than 2,000 customers. We received very positive feedback from those involved.

In 2021, we continued to hold virtual meetings and virtual plant tours around the world which contributed to the continued advancement of our strategy to provide the best service to our customers, inform them about the latest developments, identify new opportunities and expand our small plastics and jerrycan business. Through these engagements and full support from management, we identified solutions to potential challenges including supply chain issues in Russia. In Italy and Russia, we are installing equipment to produce small plastics and jerrycans for a multinational company to use across their agricultural, chemical, food and pharmaceutical businesses.

Performance

CUSTOMER SATISFACTION INDEX

NET PROMOTER SCORE*

*In 2020 Greif transitioned to conducting our NPS survey once annually.

Urgency and Innovation Earns a Customer's Trust

Greif’s Global Industrial Packaging facility in Petaling Jaya, Malaysia demonstrated customer service excellence when they rose to the occasion to solve a customer’s packaging crisis in the idle of the COVID-19 pandemic. An existing Greif customer discovered they were unable to secure unlined ultramarine blue drums, which were required to ship edible oil from one of Greif’s competitors. Since the facility did not offer that product at the time, the Petaling Jaya team quickly worked to prepare new artwork, obtain external drum color approval and create a new product stock keeping unit. The team immediately began production and secured transportation for the drums to meet the customer’s urgent need. Due to the responsiveness and ingenuity of the team in responding to this emergency, the customer has continued ordering the product from Greif.

Working with Vendor-Customers to Provide Circular Solutions

Greif’s Dalton, Georgia, PPS Recycling facility works closely with local flooring manufacturing plants to provide recycling services for tubes and cores, a significant waste stream produced by the industry. These same flooring manufacturers are also customers of Greif’s recycled paperboard tubes and cores. When the price for old corrugated cardboard (OCC) dropped in 2019, it became uneconomical to recycle these tubes and cores at market price. Greif engaged with the flooring manufacturers to develop a sustainable, circular solution that keeps waste out of landfills and allows Greif to continue providing our customers with excellent service and 100 percent recycled paperboard. Under the new business model, Greif receives payment for managing recyclable waste streams allowing us to process these materials and then send to our paper mills to manufacture 100 percent recycled paperboard.

2021 Dempsey Award for Customer Service Excellence

Greif’s 2021 Dempsey Award for Customer Service Excellence was awarded to our Greif adhesives operations within our Paper and Packaging Services business unit in Kernersville, NC and Atlanta, TX. This group earned a Customer Service Index Rating of 99.6 while facing a significant disruption in these plants’ supply chains in 2021. In February, Texas endured devastating winter storms, resulting in acetate emulsions, VAE, plasticizer and alcohol shortages. Despite the challenges, Greif adhesives operations maintained quick response times and innovative ideas. Our chemists worked weekly on replacement chemicals as various materials or additives became impossible to procure. Our plant manager collaborated with local and global sourcing colleagues to contract additional suppliers, eliminating our single-source dependency. Through all of the obstacles, 2021 was a record sales year for both adhesive plants.

CorrChoice Paper Coatings

CorrChoice GreenGuard provides customers a recyclable, repulpable and FDA compliant coated paper solution. A key customer was purchasing a triple wall corrugated container to maintain food quality. Greif worked with the customer to replace the plastic liner with our GreenGuard 200 paper coating. This change eliminated the need for the plastic liner – saving the customer time and labor costs – and made the shipping container 100 percent recyclable and repulpable.

Customer Collaboration for Improved Performance

Greif partnered with one of our global key accounts to resolve ordering process challenges and operational inefficiencies. Greif’s Global Supply Chain team, Warminster, Pennsylvania, facility and Global Account Lead partnered with the customer’s Operations Excellence and Logistics teams to design and pilot a simple-to-use Kanban process that triggers production only when product is needed. Within the first three months of implementation we achieved zero stock-outs, a seven-day lead-time reduction and a 25 percent reduction in inventory. The new process has also simplified ordering, improved visibility of customer demand for more stable production runs and improved Greif’s relationship with the customer.

PerforMAXXI

In LATAM, we introduced PerforMAXXI, a web solution used for tracking deliveries to customers and monitoring real-time performance. PerforMAXXI is a mobile app on the delivery driver’s phone that provides customers updates on where their package is in the delivery process. The app utilizes Waze or Google Maps to assist the driver and will be updated to include digital road toll payments in the second phase. The app also enables communication with the driver throughout the trip, accurate measurement of on time delivery, and electronic proof of delivery via photo of the invoice signed by the customer. The app significantly streamlines the communication and delivery process.

Nouryon Supplier of the Year Award

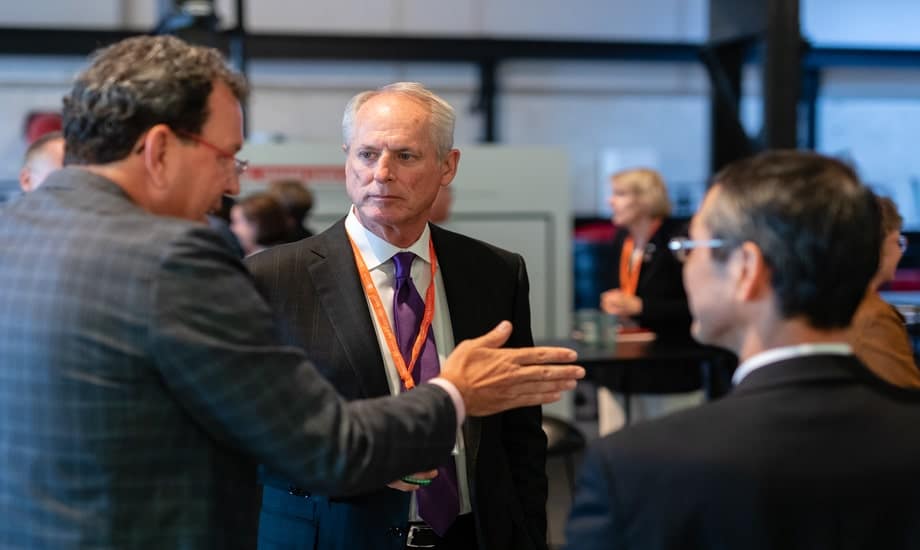

Greif is pleased to be awarded the 2021 Supplier of the Year award from Nouryon for providing excellent support during the pandemic. We were recognized for our proactive business continuity planning for the Ekabox, a customized plastic container only produced in Falkenberg, Sweden. We experienced an equipment failure, however due to our risk management and business continuity planning we were able to move Ekabox production to a third-party manufacturer. As a result, we safeguarded Nouryon and their end customers’ business without any disruptions. Photo: Hans Vanwynsberghe (left), Greif’s Director of Global Key Accounts and Philippe Marty (right), Greif’s Vice President Global Commercial Excellence receive the award from Nouryon’s Chairman and Chief Executive Officer, Charlie Shaver (middle).

SUSTAINABILITY HIGHLIGHTS

93.2

CSI Score

Our highest score ever, demonstrating our commitment to serving our customers better.

90

Customer Service Excellence Award Winners

Honoring our facilities that demonstrated best-in-class customer service performance throughout 2021.