- Sobre nossa empresa

- Sobre o nosso relatório

- Estratégias de Sustentabilidade

- Metas e Desempenho

- Índices de relatórios ESG

- Relatório de downloads

Destaques

- Gerenciamos ativamente o ciclo de vida das embalagens por meio dos processos de fabricação, recondicionamento, reutilização e reciclagem, pois os princípios da economia circular são um componente essencial da nossa estratégia Build to Last.

- A rede de serviços de ciclo de vida da Greif coleta produtos de embalagens rígidas de aço, plástico e contêineres intermediários para granéis usados e vazios e os recondiciona ou recicla, reduzindo ativamente a demanda por matérias-primas e o número de contêineres enviados para aterros sanitários.

- Nossas metas para 2030 visam tornar todos os produtos Greif recicláveis, aumentar a quantidade de matérias-primas recicladas em nossos produtos e recuperar uma porcentagem maior de material do mercado.

Por que a fabricação circular é importante

Manter e promover os princípios da economia circular é um componente importante da Estratégia Build to Last da Greif e de nossas parcerias com clientes. Gerenciamos ativamente o ciclo de vida das embalagens por meio dos processos de fabricação, recondicionamento, reutilização e reciclagem. Criar produtos que incorporem a circularidade e se baseiem no capital ambiental e social requer colaboração com nossos fornecedores, clientes e outros parceiros da cadeia de valor. O desvio de resíduos e a recuperação de materiais fortalecem nossa gestão da Economia Circular e nos permitem construir relacionamentos mais fortes com nossos fornecedores. Colaborar e construir parcerias em nossa cadeia de valor nos ajuda a desenvolver soluções sustentáveis e inovadoras para promover nossas metas coletivas, reduzir impactos ambientais, fornecer um fim de vida mais sustentável para produtos e promover nossos objetivos corporativos e de sustentabilidade.

Governança

Nossa estratégia de economia circular em nossas operações e cadeia de valor se estende além do uso de produtos reciclados, pois consideramos uma abordagem do berço ao berço. Como parte dessa estratégia, estamos trabalhando para impulsionar os princípios da economia circular em cinco áreas principais:

- Redução do uso de matéria-prima

- Redução de resíduos e redução do uso de recursos naturais

- Inovação e aumento da reciclabilidade e utilização de materiais reciclados nos nossos produtos

- Alternativas baseadas em fibras para plásticos de uso único

- Serviços de ciclo de vida

Reduzimos o uso de matéria-prima virgem aumentando nosso uso de material reciclado e por meio da redução de peso e redução de calibre de nossos produtos. Produtos de redução de peso e redução de calibre reduzem a dependência de matérias-primas e impedem que novas matérias-primas entrem em nossa cadeia de valor. Por exemplo, a Greif Latin America desenvolveu um grande tambor de plástico com uma abordagem de parede lateral facetada que removeu até 14 por cento da resina no tambor, mantendo o desempenho. O tambor facetado apoia nossas estratégias de economia circular e descarbonização, reduzindo o consumo de recursos naturais e diminuindo o uso de matéria-prima baseada em combustíveis fósseis e CO2 emissões durante o transporte.

Continuamos a projetar e desenvolver produtos recicláveis e feitos de materiais reciclados enquanto trabalhamos para atingir nossos objetivos de tornar 100% dos produtos Greif recicláveis1 e atingir uma média de 60 por cento de conteúdo de matéria-prima reciclada em nossos produtos2. Ao usar materiais reciclados e fabricar produtos recicláveis, os materiais permanecem úteis dentro de nossa cadeia de valor. Trabalhamos com nossos clientes e fornecedores para aumentar a disponibilidade e o uso de produtos reciclados e recicláveis. Nossa linha de produtos EcoBalance é feita usando até 75 por cento de polietileno de alta densidade reciclado obtido de recipientes pós-consumo e nossos produtos Paper Packaging & Services (PPS) são 99 por cento recicláveis com base no volume.

EcoBalance™ IBC reduz emissões de carbono

A Greif apoiou a produtora alemã de tintas Schulz na redução significativa de sua pegada de carbono por meio de seu contêiner intermediário a granel (IBC) sustentável GCUBE com resina pós-consumo (PCR) e serviço de reciclagem de circuito fechado.

O IBC GCUBE da Greif com PCR consiste em 60% de PE virgem e 40% de PCR. Para integridade do produto, a camada interna da garrafa IBC permanece 100% virgem de alta densidade, enquanto a camada externa é feita principalmente de PCR. Além disso, a maioria dos componentes externos, como protetores de canto, pés de plástico e paletes de plástico, são produzidos com polietileno reciclado. O PCR é gerado a partir da coleta de IBCs vazios, que são então tratados na unidade de recondicionamento e reciclagem da Greif em Mendig.

Schulz usou IBCs padrão por muitos anos e estava procurando novas maneiras de reduzir seu impacto ambiental. “A mudança para o IBC GCUBE com PCR nos ajudou a atingir nossas metas de sustentabilidade, diminuindo o consumo de matéria-prima e reduzindo as emissões de CO2 emissão na atmosfera”, explicou um porta-voz de Schulz.

O GCUBE IBC com PCR amplia a linha de produtos EcoBalance™, incluindo tambores e outros contêineres de transporte feitos usando PCR. A linha de produtos EcoBalance™ ajuda a dar suporte aos clientes da Greif com suas metas de sustentabilidade, incluindo a redução de emissões de carbono e consumo de energia e o desvio de resíduos de aterros sanitários. A linha de produtos EcoBalance™ ajuda a dar suporte aos clientes da Greif com suas metas de sustentabilidade, incluindo a redução de emissões de carbono, consumo de energia e o desvio de resíduos de aterros sanitários.

A rede Life Cycle Services (LCS) da Greif na América do Norte e Europa coleta produtos de embalagem rígida de aço, plástico e Intermediate Bulk Container (IBC) usados e vazios e fibras recuperadas e os recondiciona ou recicla para que sejam adequados para reutilização e revenda. Este trabalho reduz ativamente a demanda por matérias-primas e diminui o número de contêineres enviados para aterros sanitários. Em nosso negócio Global Industrial Packaging (GIP), recondicionamos, remanufaturamos ou reciclamos mais de 2,7 milhões de contêineres em 2022. Nosso negócio PPS gerenciou mais de 3,3 milhões de toneladas métricas de fibra reciclada em 2022. Consulte o Inovação deste relatório para obter mais informações.

Nosso objetivo é auxiliar nossos clientes e seus clientes com coletas seguras, econômicas e ambientalmente sustentáveis de embalagens usadas qualificadas. Como parte dessa rede, os clientes podem receber relatórios por meio da Greif Green Tool e da Green Tool Lite, permitindo que eles quantifiquem o impacto rastreando indicadores-chave, como redução da pegada de carbono, redução de resíduos e economia de materiais. Mais informações sobre nossos esforços de fabricação circular e seus impactos na água, resíduos e emissões podem ser encontradas neste relatório Inovação, Desperdício e Água seções.

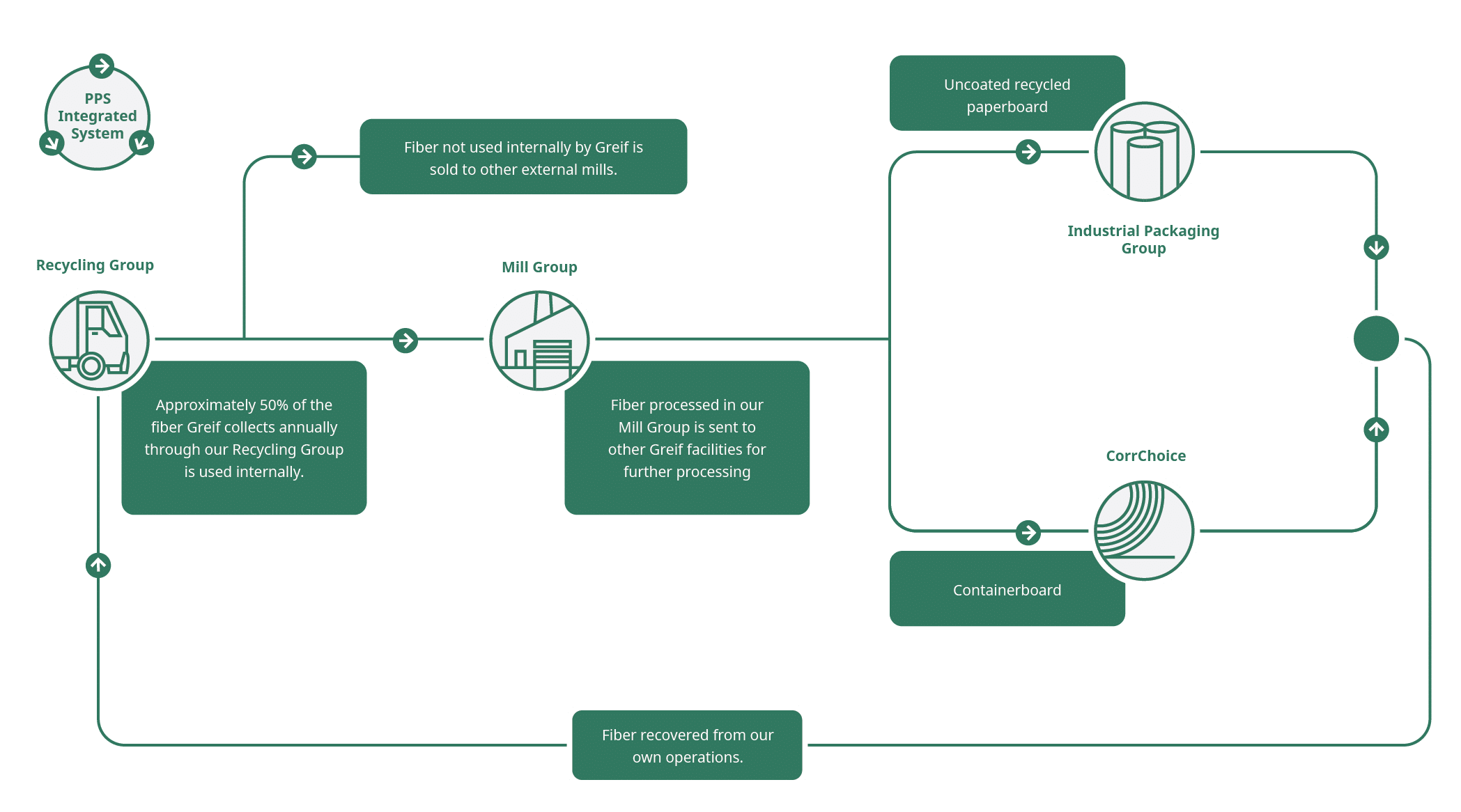

Embalagens de papel e serviços

A Greif opera 19 instalações de reciclagem em nosso negócio de PPS. Nossas instalações oferecem soluções completas de terceirização para aquisição, transporte e administração de plásticos, celulose e fibras de papel, além de fornecer soluções completas de auditoria e gerenciamento de fibras de papel. 99,2% dos produtos que nosso negócio de reciclagem manipula, em volume, são fibras de papel. Nossas operações de reciclagem de fibras de papel coletam resíduos de papel para uso em nossas fábricas de papelão para embalagens e para venda a outros fabricantes de papelão para embalagens e produtos de papel reciclado. Aproximadamente 50% da fibra que coletamos em nossas operações é usada para fabricar produtos de papel em ambientes industriais e de consumo. Coletamos os 50% restantes da fibra para venda a fábricas externas e outras operações de fabricação para produzir novos papelão, embalagens de fibra moldada e outros produtos. Mais de 78% da fibra que usamos em nossa fabricação de papel é de insumos reciclados. Devido às nossas capacidades integradas, a Greif opera como uma recicladora líquida positiva, consolidando-nos como um representante vital da indústria de reciclagem de papel.

A fibra recuperada é um insumo para muitos bens essenciais. Antes da COVID-19, o valor da fibra recuperada era historicamente baixo, com um custo de recuperação maior do que o valor da fibra para muitos recicladores. No início da COVID-19 em 2020, o fornecimento de fibra recuperada ficou aquém da demanda, resultando em escassez de fibra e custos altos contínuos. No entanto, no final de 2022, o mercado de fibras passou por uma mudança que não era experimentada há décadas, fazendo com que o preço da fibra reciclada fosse frequentemente menor do que o da fibra nova. Como resultado dessa mudança sem precedentes, agora estamos nos concentrando em reeducar os clientes sobre as vantagens da fibra reciclada. Nossos esforços de engajamento e participação de grupos da indústria ajudarão a educar o mercado sobre a dinâmica da indústria em mudança, garantindo que os bens que dependem de insumos de fibra recuperada continuem sendo negócios viáveis com uma cadeia de suprimentos robusta.

Tubos de Concreto EasyPour

Os tubos de concreto de papelão reciclado 100% de alta qualidade da Greif oferecem desempenho superior para projetos de concreto exigentes, incluindo colunas, fundações, pilares e outras estruturas. Os tubos EasyPour são um exemplo de nossos esforços para comercializar novas linhas de produtos que substituem produtos de base virgem por produtos de material reciclado e removem o plástico incorporando nossos revestimentos de barreira de base aquosa. Os tubos EasyPour também fornecem aos nossos clientes produtos que melhoraram as soluções de fim de vida, avançando assim nossa estratégia de economia circular. A tecnologia de proteção contra intempéries integrada da EasyPour fornece resistência à umidade e maior resistência e durabilidade. Os tubos EasyPour são qualificados pelo LEED®, feitos de papelão reciclado 100% produzido pelas fábricas da Greif e são totalmente recicláveis e repolpáveis. No passado, usávamos revestimentos de polietileno na fabricação de nossos tubos de construção.

Em 2021 e 2022, criamos uma alternativa de material reciclável usando papel. O desenvolvimento dessa alternativa é um passo significativo na redução de resíduos plásticos.

Embalagem Industrial Global

Nosso negócio GIP busca oportunidades de reutilização e reciclagem sempre que possível. Em média, mais de 90% dos nossos produtos plásticos são recicláveis, e 100% do nosso plástico interno remoído, que representa aproximadamente 20% dos nossos tambores e IBCs em peso, é reincorporado em nossos produtos. Fabricamos nossos produtos de aço com aproximadamente 5 a 35% de aço reciclado, dependendo da região.

Por favor, veja o nosso relatório Gestão da cadeia de abastecimento, Desperdício, e Inovação seções para mais informações sobre como nossa estratégia de economia circular abrange todo o nosso negócio.

Metas, Progresso e Desempenho

A grande quantidade de produtos de aço, plástico e papel cobertos por nossa rede LCS é um tremendo trunfo para a Greif. Em 2022, uma equipe multifuncional definiu as metas globais de circularidade da Greif e as comunicou ao mercado. A Greif está atualmente formando as equipes necessárias para atingir essas metas em cada unidade de negócios. Em 2023, planejamos automatizar a coleta de dados para nossas metas de 2030, estabelecer equipes de circularidade para supervisionar nossos fluxos de trabalho de circularidade mais importantes e desenvolver os principais itens de ação e roteiros de alto nível para nos ajudar a atingir nossas metas de 2030.

Metas para 2030:

- Tornar 100% dos produtos Greif recicláveis1.

- Alcançar uma média de 60 por cento de conteúdo de matéria-prima reciclada em todos os produtos2.

- Recuperar em média 80 por cento do material do mercado que enviamos para o mercado3.

As metas de conteúdo reciclado para produtos Greif são médias mínimas comparadas em um portfólio de materiais e produtos por peso, consolidadas em nível de empresa.

[3] As metas de recuperação para os produtos Greif são médias mínimas comparadas em um portfólio de materiais e produtos por peso, consolidadas em nível de empresa.

Usando plástico reciclado na moldagem de IBC

A unidade Tri-Sure da Greif em Carol Stream colaborou com a compra da RIPS América do Norte, a RIPS Itália e quatro plantas da RIPS NA para obter 800.000 libras de resinas plásticas recicladas para uso na produção de pés traseiros/de canto e protetores de canto do IBC. Essa estratégia de fornecimento interno reduziu os custos em $100.000. A equipe também reutilizou caixas de papelão ondulado vazias para enviar os produtos reciclados que fabrica, reduzindo as compras de caixas de papelão ondulado em 84%. O projeto criou valor para a empresa e estabeleceu benefícios ambientais e financeiros, ao mesmo tempo em que fechou dois sistemas de loop interno e contribuiu para nossa economia circular desviando resíduos de aterros sanitários e encontrando um novo propósito para eles. Devido ao excelente impacto de sustentabilidade do projeto e sua capacidade de ser dimensionado para outras instalações de moldagem e moldagem por injeção, o projeto e a equipe Tri-Sure Carol Stream receberam o Prêmio de Sustentabilidade Michael J. Gasser de 2019.

Reciclagem de fibras para a indústria de pisos

Em 2020, nossa Dalton, Georgia Recycling Facility trabalhou com os fabricantes de revestimentos de piso na área de Dalton para processar fibras recuperadas e criar um "ciclo fechado" para núcleos de papelão. A cada ano, a equipe de Dalton Recycling recupera dezenas de milhares de toneladas de resíduos de núcleo desses fabricantes e recupera essa fibra residual. Essa mesma fibra é usada pelas fábricas de papel da Greif para fabricar papelão novo 100% reciclado, que é então convertido em novos tubos e núcleos no Industrial Products Group (IPG) da Greif. Essa iniciativa ajuda não apenas a sustentar os programas de reciclagem em Dalton, mas também a manter nosso nível de excelente atendimento ao cliente com os clientes do IPG. Anualmente, esse programa ajuda a reciclar 25.000 toneladas de núcleos, 10.000 toneladas de papelão, 5.000 toneladas de papelão e 2.000 toneladas de filme plástico da indústria de pisos no norte da Geórgia.

Recondicionamento de Tambores Cónicos em Portugal

Nos últimos 20 anos, a unidade RIPS da Greif na Península Ibérica, Portugal, tem fornecido aos clientes tambores cônicos recondicionados, tendo recondicionado mais de 10 milhões de tambores e economizado 50.000 toneladas de aço, 197.600 toneladas de emissões de CO2, 2.600.000 gigajoules de energia e 343.200 metros cúbicos de água no processo. O projeto foi iniciado inicialmente como uma forma de ajudar a atender ao desejo dos nossos clientes de reduzir o desperdício e diminuir sua pegada de carbono e melhorar a satisfação geral do cliente. A equipe colaborou com os clientes para entender suas necessidades, incluindo volume, requisitos de especificação e segurança, desenvolveu um processo de recondicionamento e, finalmente, instalou uma linha de recondicionamento para começar a atender aos clientes. Hoje, a unidade atende a uma infinidade de clientes, recondicionando 500.000 tambores cônicos e economizando 5.200 toneladas de aço a cada ano.

Expandindo os serviços Cradle to Cradle com investimentos e joint ventures

Em 2020, a Greif fez investimentos e estabeleceu várias joint ventures para expandir a escala e as capacidades dos serviços de reutilização, reciclagem e recondicionamento que fornecemos. Em abril, a Greif adquiriu uma participação minoritária na Centurion Container LLC, expandindo nossa rede de recondicionamento de contêineres intermediários a granel (IBC) na América do Norte. Em agosto, a Greif estabeleceu uma joint venture com a Delta Plastics, a principal fornecedora independente de IBCs recondicionados no Reino Unido. Finalmente, em dezembro, a Greif adquiriu uma participação minoritária na LAF srl, expandindo os serviços de recondicionamento de IBC para nossos clientes na Itália. Estamos ansiosos para trabalhar com nossos parceiros para continuar a reduzir nosso impacto ambiental por meio de soluções do berço ao berço.

Serviços de recondicionamento de última geração em Lille

A unidade LCS da Greif em Lille, França, tomou medidas significativas para inovar a logística associada à oferta de serviços de recondicionamento para nossos clientes. Tradicionalmente, os IBCs vazios eram coletados e entregues em um único local para um único cliente. A LCS Lille começou a coletar em locais ao longo da cadeia de suprimentos de nossos clientes e, em seguida, entregar os IBCs recondicionados de volta aos nossos clientes, simplificando a logística para nossos clientes. Lille também implementou o Datamatrix, um sistema de rastreabilidade que nos permite registrar todas as etapas da produção, do recebimento à entrega, ter visibilidade das origens de um IBC e fornecer uma visão em tempo real do nosso inventário em suporte ao serviço geral aprimorado ao cliente. O Datamatrix também oferece suporte a um melhor gerenciamento de resíduos nos IBCs que eles coletam. Cada IBC que entra na unidade é pesado automaticamente para determinar quanto resíduo está no contêiner e informar como ele é tratado. Com o Datamatrix, essas informações podem ser enviadas diretamente de volta aos clientes para melhorar a forma como eles gerenciam os IBCs que estão prontos para coleta. Lille usa um sistema de circuito fechado para a água usada na limpeza de IBCs, reciclando 100% da água usada, e coleta, trata e tritura o plástico usado na fabricação de novos IBCs e tambores de plástico.

Fornecendo aos nossos clientes uma solução circular

A linha de produtos CorrChoice GreenGuard® fornece aos nossos clientes uma alternativa reciclável e repolpável segura para alimentos a materiais suplementares, como revestimentos plásticos. Nossa linha GreenGuard® de revestimentos de papel é segura para contato direto com a maioria dos tipos de alimentos e apresenta resistência a óleo, graxa, água, umidade e abrasão, bem como uma tecnologia inovadora de substituição de cera. Ao aplicar o revestimento em recipientes de papelão ondulado, eliminamos a necessidade de materiais suplementares usados em muitas aplicações alimentícias. Trabalhamos com nossos clientes para garantir que nossos produtos atendam às suas necessidades de manuseio seguro e protegido de alimentos, ao mesmo tempo em que fornecemos produtos de embalagem que são 100% recicláveis e repolpáveis, avançando nossa estratégia de economia circular e permitindo que nossos clientes atendam aos seus objetivos de sustentabilidade.