- Sobre nossa empresa

- Sobre o nosso relatório

- Estratégias de Sustentabilidade

- Metas e Desempenho

- Índices de relatórios ESG

- Relatório de downloads

Why Cradle to Cradle Manufacturing, Reconditioning, Reuse & Recycling Matters

Governança

Greif’s strength, as an organization, is the breadth of our products covered by our Life Cycle Services (LCS) including steel, plastic and paper products. Therefore, we are working to connect our many life cycle services across our businesses globally. Our Leadership Council prioritized sustainability this year and was divided into five teams each dedicated to a specific area of sustainability, including circularity. The circularity team was dedicated to advancing and operationalizing circularity within our operations and across our value chain. Near the end of 2021, this team created the Global Circularity Team, which is tasked with collecting data and understanding our current circular economy status to inform our 2030 targets. We will develop our 2030 circular economy goals in 2022.

Greif’s Life Cycle Services network collects used, empty, steel, plastic and Intermediate Bulk Container (IBC) rigid packaging products and reconditions or recycles them to be suitable for reuse and then reintroduces them into trade. The reconditioned containers reduce the demand for virgin raw materials while decreasing the number of containers that go to landfills. If we cannot recondition containers, we recycle the materials to use for other products. Many of Greif’s largest customers use our LCS network to recondition their containers. Customers who use the network can receive reports through the Greif Green Tool, enabling them to quantify impact by tracking key indicators such as carbon footprint reduction, waste reduction and material savings. In 2021, we developed our Greif Green Tool Lite, which houses a smaller number of products than the Greif Green Tool, but it allows us to more quickly run analyses for customers. This year, we also introduced our new IBC collections app in four countries in Europe. Through the app customers can submit requests for Greif to pick up their discarded packaging products and recondition them. We plan to expand this app to additional regions in 2022. Across Global Industrial Packaging (GIP), we reconditioned, remanufactured or recycled more than 4.5 million containers, and our Paper & Packaging Services (PPS) business managed over 3.2 million metric tons of recycled fiber in 2021.

Greif Recycling Operations

Embalagens de papel e serviços

94,991

Metric Tons of Virgin Materials Saved

Our recycling, reconditioning and reuse operations helped us remove over 94,991 metric tons of virgin steel, high-density polyethylene and wood from our supply chain in 2021.

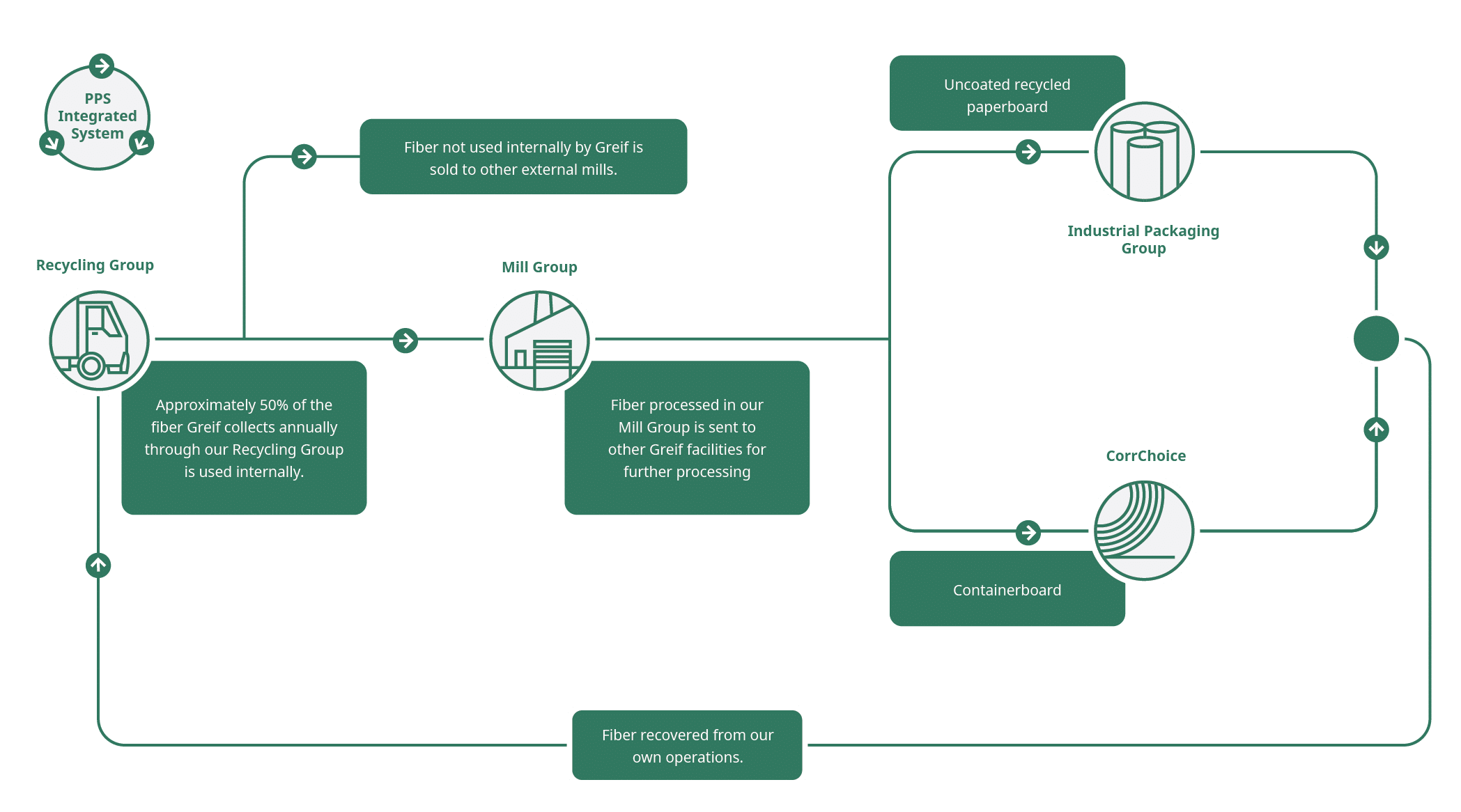

In addition to our reconditioning operations, Greif operates 19 recycling facilities in our Paper Packaging & Services (PPS) business. Through these facilities, we offer complete outsourcing solutions for plastics, pulp and paper fiber procurement, transportation and administration and provide complete paper fiber audit and management solutions. 99.2 percent of the products we handle, by volume, are paper fiber. Our paper fiber recycling operations collect waste paper for use in our own containerboard mills and for sale to other containerboard and recycled paper product manufacturers. Because of our integrated capabilities, Greif holds a central position in the paper recycling industry and operates as a net positive recycler. We use approximately 50 percent of the fiber we collect in our operations to manufacture paper products for use in consumer and industrial settings. The remaining 50 percent of the fiber we collect is sold to external mills and other manufacturing operations to produce new paperboard, molded fiber packaging and other products. More than 78 percent of the fiber we use in our paper manufacturing is from purely recycled inputs.

We are proud to be able to offer services that enable the reuse of fiber. Recovered fiber is an input to many essential goods but has suffered from reductions in supply through the economic closures caused by the global COVID-19 pandemic. Prior to COVID-19, recovered fiber value was at historical lows with the cost of recovery greater than the fiber value for many recyclers. Since the onset of COVID-19, the supply of recovered fiber has lagged behind the demand. Due to high-demand and a shortage of recycling infrastructure, there is insufficient fiber volume to satisfy demand resulting in historically high costs. Today the critical importance of expanding access to recycling is clear, particularly as more commerce takes place at the home instead of in stores. Through our sales force and participation in various industry groups, we are doing our part to educate the market on the dynamics of the changing industry to ensure this remains a viable business with a robust supply chain for all the essential goods that depend on recovered fiber inputs.

Embalagem Industrial Global

In our Global Industrial Packaging (GIP) business, we look for reuse and recycling opportunities wherever possible. 91 percent of our plastic products are recyclable and 100 percent of our internal regrind plastic, which accounts for approximately 20 percent of our drums and IBCs, is reincorporated into our products. We recycle 90 percent of our internal scrap used to produce our flexible products and the balance is sold to recycling companies. There is approximately seven percent recycled plastic (internal scrap) in our FPS plastics products. We make our steel products from approximately 15 percent recycled steel globally and 33 percent recycled steel in North America.

Cradle to cradle and the use of recycled products are just two components of our circular economy strategy that span across our operations and value chain. As part of that strategy, we are working to drive circular economy principles in five key areas:

- Reducing raw material use

- Waste reduction and reducing natural resource use

- Innovation and increasing recyclability, and use of recycled materials, in our products

- Fiber-based alternatives to single-use plastics

- Life cycle services

Please see the Gestão da cadeia de abastecimento, Desperdício, e Inovação pages of our report for more information about how our circular economy strategy spans our entire business.

In 2022, we will continue the evolution and expansion of our reconditioning services. In our PPS business, we place greater emphasis on our fiber business to identify solutions that will be valuable to our customers and work to bring them to life.

Desempenho

LIFE CYCLE SERVICES – ESTIMATED DRUMS AND IBCS RECONDITIONED*

|

|

AF 2017 |

AF 2018

|

AF 2019

|

AF 2020

|

AF 2021

|

|---|---|---|---|---|---|

|

Reciclado |

904,883 |

849,498 |

831,576 |

968,296 | 1,153,345 |

|

534,369 |

571,355 |

509,884 |

562,980 | 987,427 |

|

212,272 |

161,447 |

243,186 |

358,280 | 95,176 |

|

158,242 |

116,696 |

78,506 |

47,036 | 70,742 |

|

Recondicionado |

3,218,885 |

3,258,848 |

3,533,358 |

3,276,259 | 3,164,809 |

|

2,565,052 |

2,713,025 |

2,699,393 |

2,483,485 | 2,185,329 |

|

321,188 |

244,497 |

194,011 |

178,627 | 141,782 |

|

332,645 |

301,326 |

639,954 |

614,147 | 837,698 |

|

Total coletado |

4,136,828 |

4,105,936 |

4,348,706 |

4,164,585 | 4,345,284 |

|

3,099,633 |

3,284,380 |

3,193,049 |

2,971,549 | 3,192,196 |

|

535,460 |

405,944 |

437,197 |

536,281 | 236,958 |

|

501,735 |

415,612 |

718,460 |

656,755 | 916,130 |

|

Materiais virgens economizados por meio de recondicionamento e reutilização (toneladas métricas) |

63,111 |

63,587 |

76,415 |

71,149 | 74,713 |

|

56,200 |

57,664 |

66,860 |

62,016 | 63,143 |

|

5,150 |

4,243 |

5,897 |

5,553 | 6,610 |

|

1,761 |

1,680 |

3,659 |

3,580 | 4,960 |

|

Virgin Materials Saved by Recycling (Metric Tons)*** |

18,755 |

16,644 |

14,117 |

14,358 | 19,772 |

|

13,463 |

12,697 |

10,273 |

10,215 | 17,394 |

|

4,580 |

3,385 |

3,402 |

3,871 | 1,960 |

|

712 |

562 |

442 |

272 | 418 |

Estimativas baseadas na quantidade de embalagens recondicionadas e especificações médias de embalagens (América do Norte e Europa).

Estimativas baseadas na quantidade de embalagens recicladas e especificações médias de embalagens (América do Norte e Europa).

REBU – ESTIMATED FLEXIBLE INTERMEDIATE BULK CONTAINERS (FIBCS) RECONDITIONED EUROPE, MIDDLE EAST AND AFRICA

|

|

AF 2017 |

AF 2018 |

AF 2019 |

AF 2020 |

AF 2021 |

|---|---|---|---|---|---|

| Total FIBCs Collected | - |

316,324 |

275,732 |

242,000 |

220,132 |

|

- |

224,418 |

179,912 |

167,000 |

60,719 |

|

- |

91,906 |

95,820 |

75,000 |

159,413 |

|

Total Virgin Polyethylene Saved (Metric Tons) |

727.6 |

634.2

|

556.6 |

506.3 |

|

|

- |

516.2 |

413.8 |

384.1 |

366.6 |

|

- |

211.4 |

220.4 |

172.5 |

139.7

|

**Estimates based on the quantity of recycled packaging and average packaging specifications (Europe)

Usando plástico reciclado na moldagem de IBC

A unidade Tri-Sure da Greif em Carol Stream colaborou com a compra da RIPS América do Norte, a RIPS Itália e quatro plantas da RIPS NA para obter 800.000 libras de resinas plásticas recicladas para uso na produção de pés traseiros/de canto e protetores de canto do IBC. Essa estratégia de fornecimento interno reduziu os custos em $100.000. A equipe também reutilizou caixas de papelão ondulado vazias para enviar os produtos reciclados que fabrica, reduzindo as compras de caixas de papelão ondulado em 84%. O projeto criou valor para a empresa e estabeleceu benefícios ambientais e financeiros, ao mesmo tempo em que fechou dois sistemas de loop interno e contribuiu para nossa economia circular desviando resíduos de aterros sanitários e encontrando um novo propósito para eles. Devido ao excelente impacto de sustentabilidade do projeto e sua capacidade de ser dimensionado para outras instalações de moldagem e moldagem por injeção, o projeto e a equipe Tri-Sure Carol Stream receberam o Prêmio de Sustentabilidade Michael J. Gasser de 2019.

Fiber Recycling for the Flooring Industry

In 2020, our Dalton, Georgia Recycling Facility worked with the floor covering manufacturers in the Dalton area to process recovered fiber and create a “closed loop” for paperboard cores. Each year, the Dalton Recycling team recovers tens of thousands of tons of core waste from these manufacturers and recovers this waste fiber. This same fiber is used by Greif’s paper mills to manufacture 100 percent recycled new paperboard, which is then converted into new tubes and cores in Greif’s Industrial Products Group (IPG). This initiative helps not only sustain the recycling programs in Dalton but also maintain our level of excellent customer service with IPG customers. Annually, this program helps recycle 25,000 tons of cores, 10,000 tons of cardboard, 5,000 tons of boxboard and 2,000 tons of plastic film from the flooring industry in north Georgia.

Recondicionamento de Tambores Cónicos em Portugal

Nos últimos 20 anos, a unidade RIPS da Greif na Península Ibérica, Portugal, tem fornecido aos clientes tambores cônicos recondicionados, tendo recondicionado mais de 10 milhões de tambores e economizado 50.000 toneladas de aço, 197.600 toneladas de emissões de CO2, 2.600.000 gigajoules de energia e 343.200 metros cúbicos de água no processo. O projeto foi iniciado inicialmente como uma forma de ajudar a atender ao desejo dos nossos clientes de reduzir o desperdício e diminuir sua pegada de carbono e melhorar a satisfação geral do cliente. A equipe colaborou com os clientes para entender suas necessidades, incluindo volume, requisitos de especificação e segurança, desenvolveu um processo de recondicionamento e, finalmente, instalou uma linha de recondicionamento para começar a atender aos clientes. Hoje, a unidade atende a uma infinidade de clientes, recondicionando 500.000 tambores cônicos e economizando 5.200 toneladas de aço a cada ano.

Expandindo os serviços Cradle to Cradle com investimentos e joint ventures

Em 2020, a Greif fez investimentos e estabeleceu várias joint ventures para expandir a escala e as capacidades dos serviços de reutilização, reciclagem e recondicionamento que fornecemos. Em abril, a Greif adquiriu uma participação minoritária na Centurion Container LLC, expandindo nossa rede de recondicionamento de contêineres intermediários a granel (IBC) na América do Norte. Em agosto, a Greif estabeleceu uma joint venture com a Delta Plastics, a principal fornecedora independente de IBCs recondicionados no Reino Unido. Finalmente, em dezembro, a Greif adquiriu uma participação minoritária na LAF srl, expandindo os serviços de recondicionamento de IBC para nossos clientes na Itália. Estamos ansiosos para trabalhar com nossos parceiros para continuar a reduzir nosso impacto ambiental por meio de soluções do berço ao berço.

Ferramenta Greif Green

The Greif Green Tool is a flexible calculator that uses independent lifecycle data of Greif industrial packaging products - designed to assist our customers in making informed decisions about which industrial packaging best suits their products and to achieve their sustainability goals. The Green Tool allows customers to review and compare the environmental impact of plastic drums, steel drums, IBCs, fibre drums and big bags specifically related to their business. Results can be used to create an environmental baseline and help customers make meaningful comparisons between different packaging types and track their progress over time. To supplement the Greif Green Tool, we launched the Greif Green Tool Lite, which allows us to provide information more quickly to our customers. The Greif Green Tool Lite provides carbon footprint and reduction metrics that our customers can achieve by switching to a more sustainable product.

Serviços de recondicionamento de última geração em Lille

A unidade LCS da Greif em Lille, França, tomou medidas significativas para inovar a logística associada à oferta de serviços de recondicionamento para nossos clientes. Tradicionalmente, os IBCs vazios eram coletados e entregues em um único local para um único cliente. A LCS Lille começou a coletar em locais ao longo da cadeia de suprimentos de nossos clientes e, em seguida, entregar os IBCs recondicionados de volta aos nossos clientes, simplificando a logística para nossos clientes. Lille também implementou o Datamatrix, um sistema de rastreabilidade que nos permite registrar todas as etapas da produção, do recebimento à entrega, ter visibilidade das origens de um IBC e fornecer uma visão em tempo real do nosso inventário em suporte ao serviço geral aprimorado ao cliente. O Datamatrix também oferece suporte a um melhor gerenciamento de resíduos nos IBCs que eles coletam. Cada IBC que entra na unidade é pesado automaticamente para determinar quanto resíduo está no contêiner e informar como ele é tratado. Com o Datamatrix, essas informações podem ser enviadas diretamente de volta aos clientes para melhorar a forma como eles gerenciam os IBCs que estão prontos para coleta. Lille usa um sistema de circuito fechado para a água usada na limpeza de IBCs, reciclando 100% da água usada, e coleta, trata e tritura o plástico usado na fabricação de novos IBCs e tambores de plástico.

Fornecendo aos nossos clientes uma solução circular

A linha de produtos CorrChoice GreenGuard® fornece aos nossos clientes uma alternativa reciclável e repolpável segura para alimentos a materiais suplementares, como revestimentos plásticos. Nossa linha GreenGuard® de revestimentos de papel é segura para contato direto com a maioria dos tipos de alimentos e apresenta resistência a óleo, graxa, água, umidade e abrasão, bem como uma tecnologia inovadora de substituição de cera. Ao aplicar o revestimento em recipientes de papelão ondulado, eliminamos a necessidade de materiais suplementares usados em muitas aplicações alimentícias. Trabalhamos com nossos clientes para garantir que nossos produtos atendam às suas necessidades de manuseio seguro e protegido de alimentos, ao mesmo tempo em que fornecemos produtos de embalagem que são 100% recicláveis e repolpáveis, avançando nossa estratégia de economia circular e permitindo que nossos clientes atendam aos seus objetivos de sustentabilidade.

DESTAQUES DE SUSTENTABILIDADE

4.5 M

Containers Collected, Recycled and Reconditioned

Through our Life Cycle Services network, we collected, recycled and reconditioned steel drums, poly drums, IBCs and FIBCs.

94,991

Metric Tons of Virgin Materials Saved

Our recycling, reconditioning and reuse operations helped us remove over 94,991 metric tons of virgin steel, high-density polyethylene and wood from our supply chain in 2021.