- Sobre nossa empresa

- Sobre o nosso relatório

- Estratégias de Sustentabilidade

- Metas e Desempenho

- Índices de relatórios ESG

- Relatório de downloads

Destaques

- Greif’s approach to innovation encourages all parts of the company to participate in transforming our product portfolio and organizational processes.

- We evaluate, prioritize and elevate projects based on potential financial return, sustainability impact and overall value to Greif and our customers.

- In 2023, Greif had more than $822 million in revenue from sustainability-tagged products from our Global Industrial Packaging (GIP) business and life cycle services offered by our Paper Packaging & Services (PPS) and GIP businesses.

Why Innovation Matters

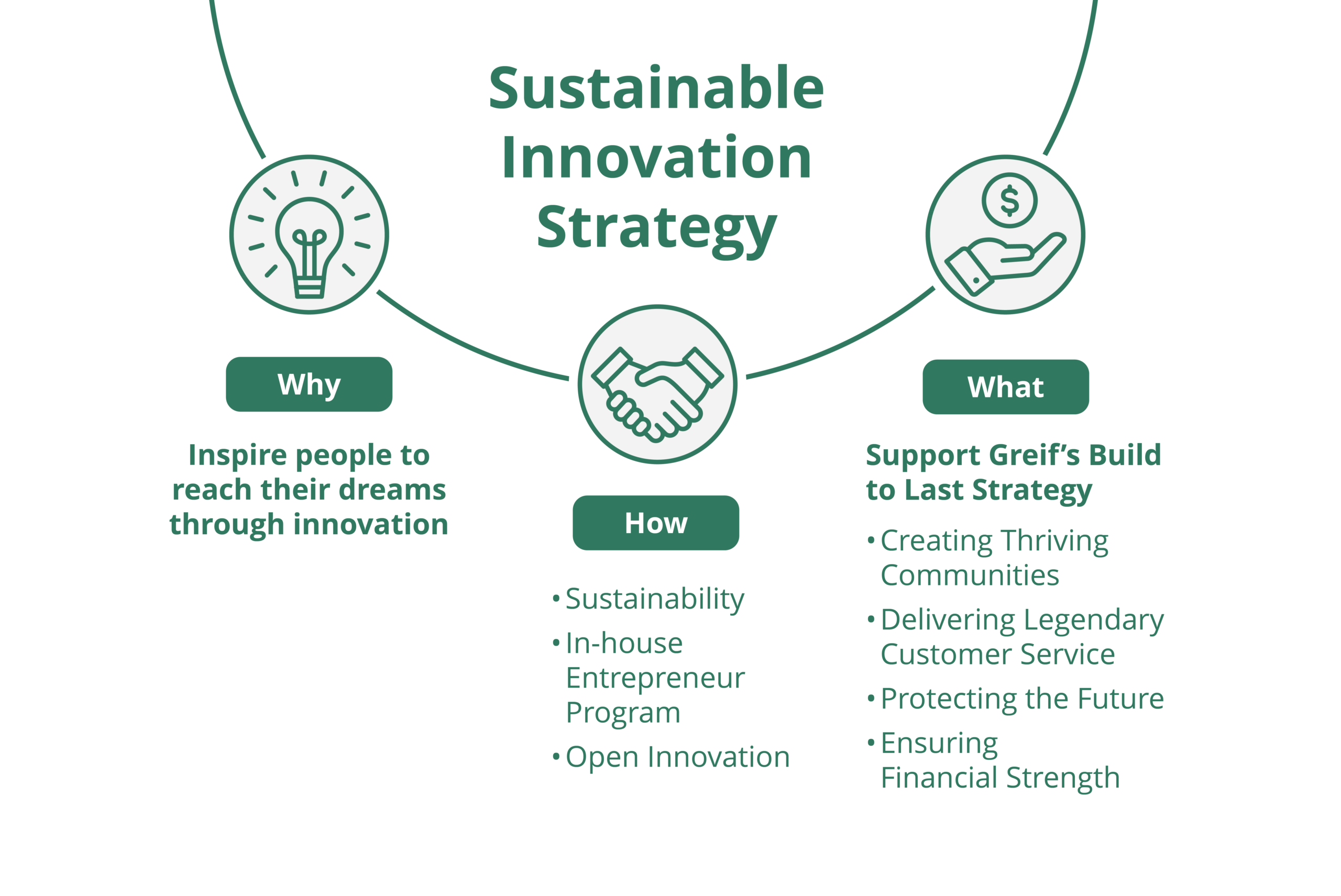

Innovation at Greif helps to drive our organizational mission and is crucial in addressing customers’ operational challenges and packaging needs. Our focus on product innovation aligns with several missions of our Build to Last Strategy. For example, our Protecting Our Future mission comes to life in developing new, more sustainable products and services that ultimately help advance a low-carbon and circular economy future. As part of our Creating Thriving Communities mission, we prioritize colleague safety and safeguard customer health through the continual advancement of process innovation.

Governança

Greif’s approach to innovation encourages all parts of the company to participate in transforming our product portfolio and organizational processes. Our Global Innovation Team is made up of representatives from each business unit. Led by the Director of Sustainable Innovation, the team facilitates a cohesive and collaborative environment for idea-sharing and cross-enterprise collaboration. Our In-House Entrepreneur Program establishes a coordinated approach for colleagues at all levels to contribute ideas and foster innovation. Quarterly project reviews are held with the Executive Leadership Team and the Board of Directors to communicate updates on innovation priorities and industry trends that can impact our business.

At the end of 2023, the Director of Sustainable Innovation began reporting through Greif’s Global Operations Group, enhancing connectivity with cross-functional teams and providing expanded resources for project implementation.

Colleague Engagement in Innovation

Our Sustainability Innovation Strategy strives to inspire colleagues to reach their dreams through innovation. We believe a company culture of innovation fosters a dynamic and engaging work environment, encouraging creative problem-solving and continuous learning for our colleagues. Our In-House Entrepreneur Program empowers Greif colleagues to generate and implement innovations that meet customer demands for sustainability, improve Greif's processes and expand our business to new markets. In 2023, the program was allocated a budget for experimenting with and testing colleague ideas. Approximately 90 percent of innovations in the program have sustainability benefits.

In 2023, we introduced our Innovator of the Month recognition program to acknowledge and celebrate colleagues who contribute significantly to our innovation initiatives.Greif’s sustainable packaging solutions are developed using eight environmental, social and financial criteria and focus on the principles of circularity and dematerialization. Working with customers, we create products that meet required performance and safety standards while minimizing environmental impacts through design features such as lightweighting, incorporating recycled raw materials and designing for recyclability and reduced emissions. Our innovation strategy takes a holistic approach and assesses projects based on financial returns, sustainability impact and overall value to Greif and our customers.

Greif Green Tool and Greif Green Tool Lite

The Greif Green Tool and Greif Green Tool Lite help us collaborate with customers on sustainability. The Greif Green Tool, a flexible calculator based on ISO 14040/14044 standards and independent life cycle analysis of Greif Global Industrial Packaging products, provides customers with valuable insights into the impacts of packaging, transportation and product end-of-life scenarios on greenhouse gas emissions. Customers can create environmental baselines and compare different options to support more sustainable decision-making and help them meet their goals. Additionally, the Greif Green Tool Lite, designed in response to increased customer demand, offers more efficient access to carbon footprint and reduction metrics for our top-selling intermediate bulk containers, drum products and jerrycans. Continual updates and incorporation of our latest product information ensures the tool's data and classifications remain current.

Our innovation priorities continuously adapt to each business unit’s unique needs and customers. Within our GIP business, ongoing efforts focus on implementing sustainable product projects to reduce material use. Innovative ideas are explored to address factors such as carbon footprint reduction, environmental impact minimization, incorporation of recycled raw materials and efficient raw material utilization.

In our PPS business, we collaborate with customers to create innovative, sustainable solutions. Our core development and strategy teams meet monthly to review progress and associated challenges of innovation projects, while our Innovation Team meets quarterly to monitor progress against our innovation objectives. Our efforts focus on reducing single-use plastic and non-recyclable products through recycled material-based alternatives and eliminating plastic via our barrier coatings. Recycled inputs and compostable paperboard products, such as food-grade packaging and EasyPour® construction cores, minimize carbon footprints, deliver cost savings and expand our presence in new markets. Additionally, our new Environmentally Smart (ES) Natural product has replaced a virgin fiber-based product in the construction industry. In FY23, ES Natural replaced 2,965 U.S. tons of virgin raw materials.

Innovation is also an important part of how we protect the health and safety of our colleagues and the consumers who use our products. Our Innovation Team collaborates closely with colleagues at various plants to develop transformative solutions or implement technology to make processes safer. For example, we are testing a virtual reality safety training program for colleagues to practice safety actions without risking injury or harm.

Metas, Progresso e Desempenho

As innovation continues to drive our circularity efforts and product development, we are concentrating on post-consumer resin products and reconditioning to advance the circular economy. (For more information on our circularity initiatives, please see the Fabricação Circular section of this report.) Additionally, we have increased our attention on plastic treatment to find alternatives to potential PFAS-generating technologies currently in use and to improve product safety.

In addition, innovation also has a role to play in customer service. We are actively working to improve our products by collaborating with internal and external customers. To support future collaboration, the Global Innovation Team plans to enhance proactive customer engagement by working with Greif’s commercial teams and increasing customer site visits. We aim to gain firsthand insights into unmet customer needs to inform our innovation strategies.

In 2023, Greif had more than $822 million in revenue from sustainability-tagged products from GIP and life cycle services offered by our GIP and PPS businesses.

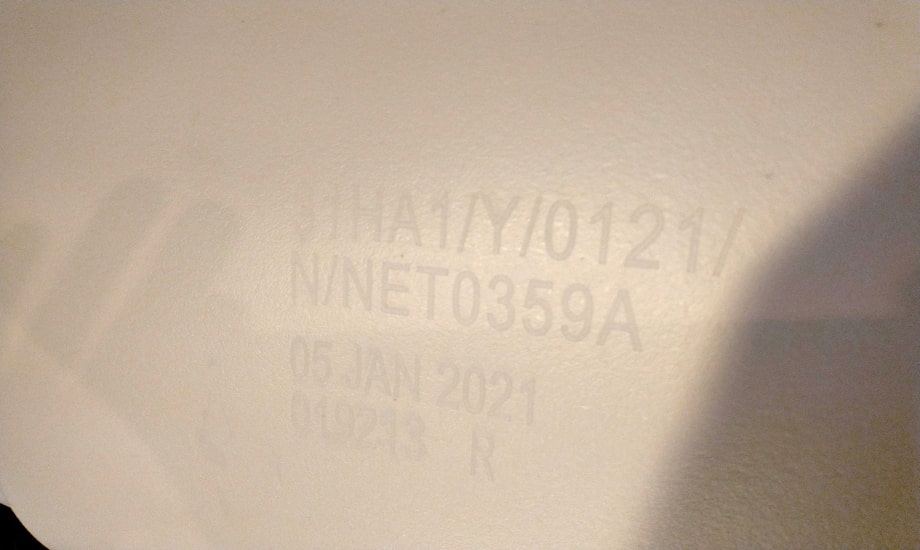

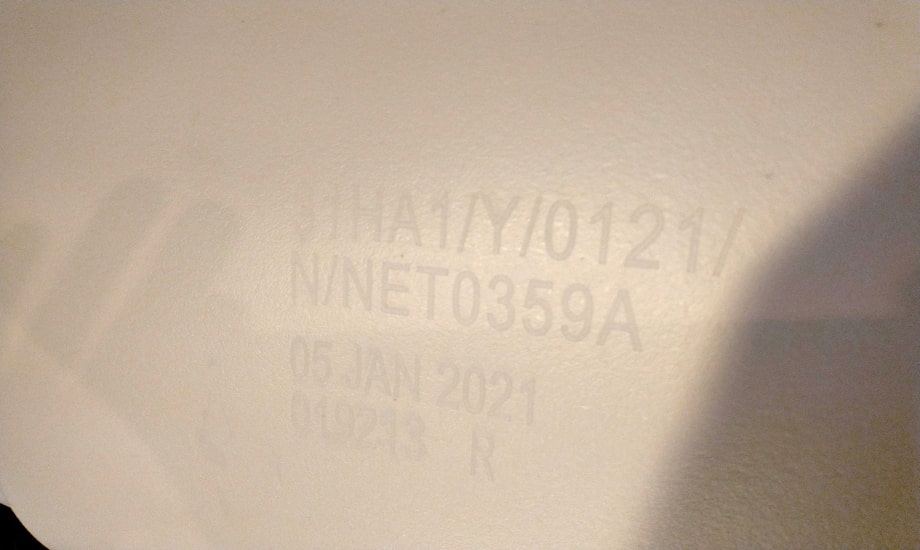

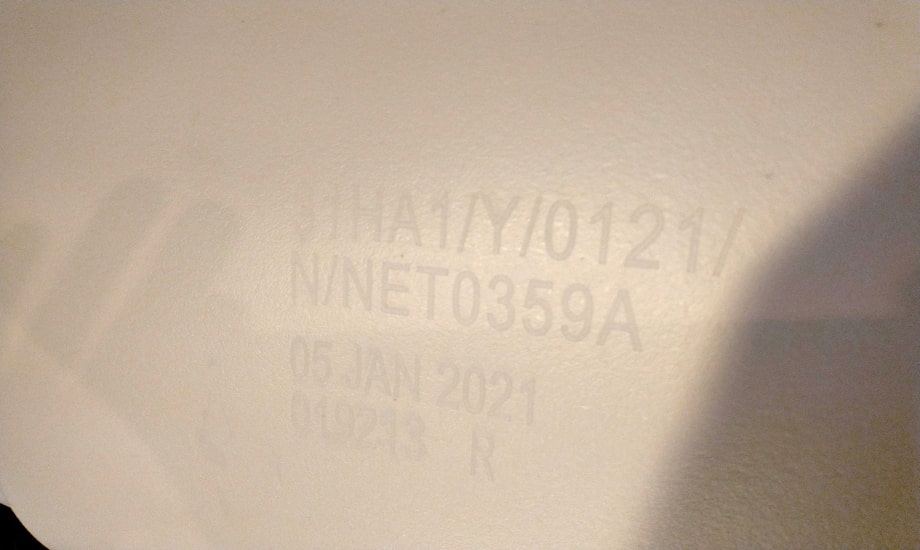

Laser Markings on IBCs

Greif Sweden/Nordic is the first in the market to replace ink jet markings with laser markings on Intermediate Bulk Containers (IBCs), reducing the use of solvent-based ink during production. By eliminating the use of solvents and ink, the production environment is cleaner. We also are able to reduce the weight of the IBC by one kilogram by removing the plate traditionally used for laser marking. We believe this innovation will set a new standard for markings on IBCs.

Knock Down Drums (KDD) for Remote Locations

Greif’s Knock Down Drums (KDD) offer the optimal sustainable solution for transporting steel drums to remote locations. Semi-finished drum parts are shipped and assembled locally on site with minimum people and equipment. The unique concept allows transportation of up to 1,176 KDDs in a 20’ sea container compared to 80 full finished drums, saving valuable space, optimizing transport costs and minimizing our customers' carbon footprint during longer transit times. Drums are delivered directly to our customers' filling station helping to improve efficiencies with minimum stock and less manual handling.

Lightweighting and Innovating the Shape of Jerrycans

Greif manufactured our first lighter weight 20 and 25-liter jerrycan models in 2015. This design is 15 percent lighter than the previous model while maintaining performance specifications of the previous design. Due to the reduced weight, the new jerrycans reduce materials and energy used in production by up to 15 percent and have a reduced emissions impact. In 2019, we expanded this product line to include sizes 16 and 18 liters. We now produce our lighter jerrycans in Italy, Israel, Sweden and Singapore.

ECOEX Jerrycans

COEX multilayer plastic packaging combines several layers of different plastics materials into a single structure and offers many barrier performance benefits, particularly for agrochemical and food packaging applications. However, when reground, COEX plastics can only be used in low performance applications. In response to our customers’ need for recyclable packaging with superior barrier performance, we created our ECOEX line of jerrycans. The ECOEX technology enables Greif to produce an innovative, multilayer jerrycan that can be recycled through regrinding processes to produce high performing, UN Certified jerrycans and bottles. ECOEX also reduces costs for our customers who typically pay an increased collection fee for COEX packaging collection after use. We continue to drive innovation that supports our circular economy strategy and meets our customers’ needs. The LATAM GIP team was awarded the 2021 Michael J. Gasser Sustainability Award for their contribution towards our circular economy strategy while meeting the needs of our customers.

A Lighter Approach

In order to respond to customer demands to remove weight and optimize transportation costs, our Greif Latin America colleagues designed a novel plastic drum innovation using a never seen before facetted side-wall approach for large plastic drums. This improvement removed up to 14 percent of the resin in the drum while maintaining performance. Not only does the design reduce raw material usage, it also optimized pallet utilization due to its unique configuration which allows more drums to be transported in the same space as the legacy design. The faceted drum is a more sustainable solution both in reducing natural resource consumption and lowering fossil fuel-based raw material usage and CO2 emissions during transportation.

Better Branding with Drum 360

At Greif, we now have the ability to print high-resolution images directly onto steel drums using the latest print technologies. This capability is the direct result of an investment designed to meet the needs of customers who are looking for ways to differentiate their products and generate impactful packaging design to support the price point of high value products. In addition to adding value for our customers, this process eliminated the need for a standard gas oven, using LED-based UV curing during the production process. This new process saves 0.5 kilograms CO2 per drum. Greif strategically placed the new Drum 360 technology in plants close to customers who use this new technology, in the Belgium, France, Netherlands, Italy, Germany and Poland.

GCUBE Connect: Real-time Tracking for your IBCs

Greif’s GCUBE Connect solution, launched at LogiChem virtual conference, gives real time tracking information about a customer’s IBC through the application of an Internet of Things-based device. A customer-based dashboard displays in real time where an IBC is sited, the level of the filled product and the environmental temperature. This dashboard allows customers to plan in advance for deliveries of filled product and the arrival of new IBCs, as well as schedule collections of empty IBCs. GCUBE Connect also supports better management of residue in the IBCs. Each IBC that enters the facility is automatically weighed to determine how much residue is in the container to determine how it will be treated. This innovation pairs well with Greif France’s ability to pick up and drop off reconditioned IBCs from any site along a customer’s supply chain, as opposed to one single location. Together, they simplify the logistics for the customer and increase transparency.

Inovação

- Sobre nossa empresa

- Sobre o nosso relatório

- Estratégias de Sustentabilidade

- Metas e Desempenho

- Índices de relatórios ESG

- Relatório de downloads

Destaques

- In 2022, we started a new function for sustainable innovation and dedicated appropriate and significant resources to ensure its initial success. We are committed to creating shared value for customers, shareholders and the environment through sustainable innovation.

- Our robust definition of innovation encourages all parts of the company to participate in transforming our product portfolio and organizational processes.

- Our innovation approach evaluates, prioritizes and elevates projects based on potential financial return, sustainability impact and overall value to Greif and our customers.

- Over $1 billion of our fiscal year 2022 revenue is attributed to sustainability-tagged products and services.

Why Innovation Matters

Prioritizing innovation allows Greif to grow and evolve alongside our customers toward a more sustainable future. We seek opportunities to improve our products and processes by conducting thorough analyses of our value chain, from raw material extraction to product end-of-life. The Protecting Our Future mission within our Build to Last strategy is focused on embracing a low-carbon and circular economy future by innovating new, more sustainable products that reduce our negative impacts on the environment and create a positive impact.

Governança

Our robust definition of innovation encourages all parts of the company to participate in transforming our product portfolio and organizational processes. In 2022, we stood up a new function for sustainable innovation and dedicated appropriate and significant resources to ensure its initial success. Innovation is managed by our Director of Sustainable Innovation and Global Innovation Team, comprising representatives from each of Greif’s business units. The team structure facilitates idea-sharing and collaboration across the enterprise. In 2022, we standardized procedures to create a unified process for colleagues at every level of the organization to share ideas and drive innovation through our Growth Board Process. The team regularly meets with Greif’s Executive Leadership Team (ELT) and the Greif Board of Directors, providing progress updates on innovation priorities and industry trends that may influence investment and overall company strategy in the future.

We use eight environmental, social and financial criteria to guide the development of our sustainable packaging solutions. Circularity and dematerialization principles are the central focus of these criteria and our innovation efforts. Alongside our internal innovation programs, we collaborate with our customers to deliver products that are lighter weight, utilize more recycled raw materials and are designed for recyclability and fewer emissions while continuing to meet performance and safety requirements. Our innovation approach evaluates, prioritizes and elevates projects based on potential financial return, sustainability impact and overall value to Greif and our customers.

The Greif Green Tool continues to be essential for us to communicate our innovations and sustainable products and solutions. We observed a significant increase in customer requests to use this tool in 2022. The Greif Green Tool enables us to give customers insights into how various packaging options, transportation options and product end scenarios impact GHG emissions. We plan to update the tool with our latest product information to ensure data and product classifications remain up to date.

The Greif Green Tool Lite, a simpler version of our Green Tool, provides carbon footprint and reduction metrics for our most-sold IBCs and fiber, plastic and steel drum products. Due to the number of customer requests for Greif Green Tool analyses, we developed the Lite version to provide detailed environmental impact data more efficiently for our most-sold products.

Greif Green Tool

The Greif Green Tool is a flexible calculator that uses independent lifecycle data of Greif industrial packaging products - designed to assist our customers in making informed decisions about which industrial packaging best suits their products and to achieve their sustainability goals. Developed by a third party to be based on ISO 14040/14044 standards, the Green Tool allows customers to review and compare the environmental impact of plastic drums, steel drums, IBCs, fiber drums and big bags specifically related to their business. Results can be used to create an environmental baseline and help customers make meaningful comparisons between different packaging types and track their progress over time. To supplement the Greif Green Tool, Greif Green Tool Lite allows us to quickly provide information to our customers. The Greif Green Tool Lite provides carbon footprint and reduction metrics that our customers can achieve by switching to a more sustainable product.

Our innovation priorities vary based on the specific needs of each of our business units and their customers. In 2022, our Global Industrial Packaging (GIP) business continued to institute multiple sustainable product projects to reduce material use. For example, some innovative ideas may include aspects that reduce carbon footprint, reduce the impact on other environmental factors and use less raw material.

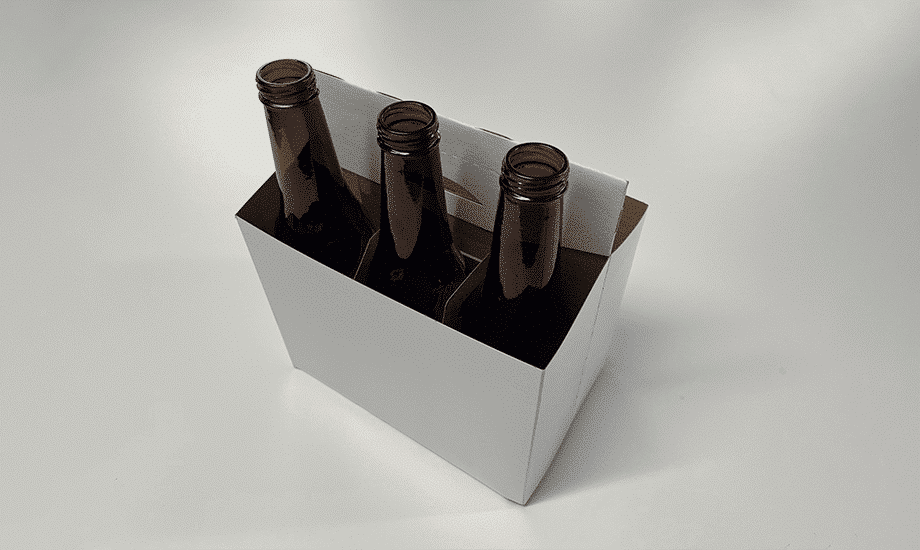

Across our Paper Packaging & Services (PPS) business, we collaborate closely with our customers to develop innovative solutions to meet their performance and sustainability needs. Each month, our core development and strategy teams meet to discuss the progress of innovation projects within PPS and act on any challenges. The Innovation Team meets quarterly to ensure sustained progress against our innovation objectives. We continue to develop innovative, recycled material-based products that replace virgin-based products and remove plastic by incorporating our barrier coatings. We improve our circular economy strategy and meet customers’ demands for enhanced end-of-life solutions by developing recycled and compostable paperboard products. These products include paperboard for food-grade packaging, food service items, beverage carriers and EasyPour® construction cores. Through these innovative products and collaboration with customers, we reduced our and our customers’ carbon footprints, enhanced brand value by entering new markets and realized cost savings. PPS commercialized many sustainable products in 2022 that have replaced significant quantities of single-use plastic packaging and other non-recyclable products.

Meeting Consumer Demand for More Sustainable Packaging

Consumer demand for sustainable food and beverage packaging is increasing demand for more sustainable products. Our PPS business works with customers and partners to develop innovative products that replace virgin-based products with recycled material products or products that replace plastic from packaging with our barrier coatings. We developed the EnviroBevTM beverage carrier to replace a virgin-based product with a 100% recycled, wet-strength material for craft brewery beverage carriers. In 2021, PPS also commercialized food-grade packaging—cupstock, platestock and bowls—made from recycled fiber with an aqueous-based coating. This coating replaces the polyethylene extrusion typically used in food-grade packing, enabling the packaging to be more readily composted or recycled. Combined, these innovations will replace 14,000 tons of virgin-based material with recycled material. The PPS Innovation Team was awarded the 2021 Michael J. Gasser Sustainability Award for their contribution toward our circular economy strategy while meeting the needs of our customers.

Metas, Progresso e Desempenho

In 2022, we introduced a Growth Board Process that allows Greif colleagues to become in-house entrepreneurs. The Growth Board process empowers Greif colleagues to generate, develop, evaluate and implement innovations that meet customer demand for sustainable products and services, provide process efficiencies and improvements or open our products portfolio to new markets. In its first year, we have seen significant interest and progress across our innovation priorities through the Growth Board Process. Additionally, as part of our strategy to advance the circular economy, Greif has increased its focus on post-consumer resin (PCR) products and reconditioning.

In 2022, Greif had over $1 billion in revenue from sustainability-tagged products and services, including life cycle services, for Greif’s Global Industrial Packaging (GIP) business unit.

Laser Markings on IBCs

Greif Sweden/Nordic is the first in the market to replace ink jet markings with laser markings on Intermediate Bulk Containers (IBCs), reducing the use of solvent-based ink during production. By eliminating the use of solvents and ink, the production environment is cleaner. We also are able to reduce the weight of the IBC by one kilogram by removing the plate traditionally used for laser marking. We believe this innovation will set a new standard for markings on IBCs.

Knock Down Drums (KDD) for Remote Locations

Greif’s Knock Down Drums (KDD) offer the optimal sustainable solution for transporting steel drums to remote locations. Semi-finished drum parts are shipped and assembled locally on site with minimum people and equipment. The unique concept allows transportation of up to 1,176 KDDs in a 20’ sea container compared to 80 full finished drums, saving valuable space, optimizing transport costs and minimizing our customers' carbon footprint during longer transit times. Drums are delivered directly to our customers' filling station helping to improve efficiencies with minimum stock and less manual handling.

Lightweighting and Innovating the Shape of Jerrycans

Greif manufactured our first lighter weight 20 and 25-liter jerrycan models in 2015. This design is 15 percent lighter than the previous model while maintaining performance specifications of the previous design. Due to the reduced weight, the new jerrycans reduce materials and energy used in production by up to 15 percent and have a reduced emissions impact. In 2019, we expanded this product line to include sizes 16 and 18 liters. We now produce our lighter jerrycans in Italy, Israel, Sweden and Singapore.

ECOEX Jerrycans

COEX multilayer plastic packaging combines several layers of different plastics materials into a single structure and offers many barrier performance benefits, particularly for agrochemical and food packaging applications. However, when reground, COEX plastics can only be used in low performance applications. In response to our customers’ need for recyclable packaging with superior barrier performance, we created our ECOEX line of jerrycans. The ECOEX technology enables Greif to produce an innovative, multilayer jerrycan that can be recycled through regrinding processes to produce high performing, UN Certified jerrycans and bottles. ECOEX also reduces costs for our customers who typically pay an increased collection fee for COEX packaging collection after use. We continue to drive innovation that supports our circular economy strategy and meets our customers’ needs. The LATAM GIP team was awarded the 2021 Michael J. Gasser Sustainability Award for their contribution towards our circular economy strategy while meeting the needs of our customers.

A Lighter Approach

In order to respond to customer demands to remove weight and optimize transportation costs, our Greif Latin America colleagues designed a novel plastic drum innovation using a never seen before facetted side-wall approach for large plastic drums. This improvement removed up to 14 percent of the resin in the drum while maintaining performance. Not only does the design reduce raw material usage, it also optimized pallet utilization due to its unique configuration which allows more drums to be transported in the same space as the legacy design. The faceted drum is a more sustainable solution both in reducing natural resource consumption and lowering fossil fuel-based raw material usage and CO2 emissions during transportation.

Better Branding with Drum 360

At Greif, we now have the ability to print high-resolution images directly onto steel drums using the latest print technologies. This capability is the direct result of an investment designed to meet the needs of customers who are looking for ways to differentiate their products and generate impactful packaging design to support the price point of high value products. In addition to adding value for our customers, this process eliminated the need for a standard gas oven, using LED-based UV curing during the production process. This new process saves 0.5 kilograms CO2 per drum. Greif strategically placed the new Drum 360 technology in plants close to customers who use this new technology, in the Belgium, France, Netherlands, Italy, Germany and Poland.

GCUBE Connect: Real-time Tracking for your IBCs

Greif’s GCUBE Connect solution, launched at LogiChem virtual conference, gives real time tracking information about a customer’s IBC through the application of an Internet of Things-based device. A customer-based dashboard displays in real time where an IBC is sited, the level of the filled product and the environmental temperature. This dashboard allows customers to plan in advance for deliveries of filled product and the arrival of new IBCs, as well as schedule collections of empty IBCs. GCUBE Connect also supports better management of residue in the IBCs. Each IBC that enters the facility is automatically weighed to determine how much residue is in the container to determine how it will be treated. This innovation pairs well with Greif France’s ability to pick up and drop off reconditioned IBCs from any site along a customer’s supply chain, as opposed to one single location. Together, they simplify the logistics for the customer and increase transparency.

Inovação

- Sobre nossa empresa

- Sobre o nosso relatório

- Estratégias de Sustentabilidade

- Metas e Desempenho

- Índices de relatórios ESG

- Relatório de downloads

Why Innovation Matters

Prioritizing innovation enables Greif to reduce our footprint and support our customers’ desire for safer, more sustainable products and reduced transportation costs. As we continue to innovate, we advance sustainable packaging and circular economy principles. We analyze our entire value chain—from the extraction of raw materials to our products’ end-of-life—to find opportunities to improve our products and processes. This strategy is not only the right thing to do but provides us a competitive advantage.

Governança

$872 M

Revenue from Sustainability-tagged Products

In 2021, Greif had $872,376,716 in revenue from sustainability-tagged products for Greif’s GIP business unit.

Our innovation efforts focus on transforming our product portfolio by developing sustainable packaging solutions based on a set of eight environmental, social and financial sustainability criteria. Through internally-initiated solutions and collaboration with customers, our innovation efforts focus on dematerialization and circularity principles—producing products that are lighter weight, utilize more recycled raw materials and designing for recyclability and circularity—and green material substitution—identifying safer materials to produce our products—while continuing to meet performance requirements. Innovation is managed by our Global Innovation Committee, comprised of representatives from each of Greif’s business units. The committee structure facilitates idea sharing and collaboration across the enterprise. In 2021, the committee standardized procedures so colleagues at every level of the organization have a unified process to share ideas and drive innovation. The committee meets with Greif’s Executive Leadership Team (ELT) quarterly providing progress updates on innovation priorities and industry megatrends that may influence investment and overall company strategy in the future. Our innovation approach evaluates and prioritizes projects based on potential financial return, sustainability impacts and overall value to Greif and our customers. In 2021, Greif had $872,376,716 million in revenue from sustainability-tagged products for Greif’s Global Industrial Packaging (GIP) business unit, including life cycle services.

In 2019, we developed our inaugural “Greif Global Innovation Trends Report” that identified six trends that are strategically relevant to Greif:

- Companies are Becoming More Environmentally Friendly

- Digitization & Automation of Manufacturing

- Digitization of Supply Chain & Logistics

- Digitization of Enterprise Purchasing & Business-to-Business Selling

- Workforce Shortages, Surpluses & Skill Gaps

- Growth Opportunities Increasing in Emerging Markets

The Greif Green Tool continues to be an important tool for us to communicate our innovations and sustainable products to our customers. Since its inception, we have partnered with many of our key global accounts to evaluate the GHG emissions associated with different packaging options, product end-of-life scenarios and transportation options. In 2021 we continued to engage with our customers using the Greif Green Tool providing more complex analyses in support of lowering their carbon footprint through packaging and logistic optimization solutions. In 2022, we will update the tool with our latest product information, ensuring data and product classifications are up to date. As a result of the update, the tool will include more life cycle services, reconditioning and recycling data.

In 2021, we also developed the Greif Green Tool Lite. As our customers continue to set scope 3 targets, the demand for product emissions data has only increased. We designed the Green Tool Lite to provide answers to our customers more quickly. The Greif Green Tool Lite provides carbon footprint and reduction metrics that our customers can achieve by switching to a more sustainable product. Customers can use the tool for our most-sold IBCs and fibre, plastic and steel drum products. We will continue to advance our digital services to provide our customers innovative solutions and the best customer service experience in industrial packaging.

Our innovation priorities vary based on the specific needs of each of our business units and their customers. In 2021, our Global Industrial Packaging (GIP) business continued to institute multiple sustainable product projects to reduce material use, and we will begin to look into zero carbon packaging options. Similarly, our Flexible Products & Services (FPS) business also advanced multiple sustainable product projects to reduce material use that, collectively, are estimated to generate 380 tons of material savings annually. The business unit also worked with our stakeholders to maintain our position as a market leader in food safety and meet emerging compliance requirements as part of our Food Safety Initiative. In 2019, we formalized our integrated ISO-certified food manufacturing practice program, which involves integrating basic food safety procedures into our quality management system. At the end of 2021, 100 percent of our GIP North America facilities were compliant with the new standards.

Our innovation efforts also address regionally specific needs and can go beyond our products. Greif’s Latin American (LATAM) offices are encouraging innovation in their working environment. In 2019, the team began hosting interactive and in-person innovation workshops to teach our colleagues about innovation and brainstorm not just product and process ideas, but innovations we can bring to our working environment to be a better and more attractive employer for current and future colleagues. In 2020, our LATAM team began conducting bi-weekly reviews with members of the innovation team to spread innovative practices that are already in place, identify new innovation opportunities and discuss non-product innovation opportunities to better serve our customers. Through these continued efforts, Greif LATAM developed a facetted side-wall design for lightweight drums and ECOEX jerrycans.

Across our Paper Packaging & Services (PPS) business we work in close collaboration with our customers to develop innovative solutions to meet their performance and sustainability needs. Each month, our core development and strategy team meets to discuss the progress of innovation projects within PPS and take action on any challenges. Quarterly, an innovation team meets to ensure continued progress against our innovation objectives. We continue to develop innovative, recycled material products that replace virgin-based products and remove plastic by incorporating our barrier coatings. Made of recyclable and/or compostable paperboard, our products provide customers with improved end-of-life solutions and advance our circular economy strategy. These products include paperboard for food grade packaging, food service items, beverage carriers and EasyPour® construction cores. By working with our customers to provide sustainable products, we reduced our and our customers’ carbon footprints, enhanced brand value by entering new markets and realized cost savings. PPS commercialized many such sustainable products in 2021 that have replaced over 50,000 tons of single-use plastic packaging and other non-recyclable products.

The COVID-19 pandemic has created challenges globally, but we have adopted new processes and procedures to conduct business efficiently and effectively while protecting the health and safety of our colleagues and partners. We have utilized online platforms to host conferences, virtual tours and forums. We have also held customer webinars to demonstrate changes to our products and processes, our life cycle services, sustainability, our product portfolio and other key topics.

In 2022, we will continue to have innovation at the core of our business practices. We plan to focus on new barrier technologies for plastics, jerrycan designs, PCR products, knock down drum offerings across specific markets in LATAM, anti-counterfeiting measures and Internet of Things technologies. We will also prioritize acquiring additional UN ratings for our products.

Goals & Progress

*Global revenue from sustainability-tagged products for Greif’s Global Industrial Packaging (GIP) business unit, including life cycle services.

Laser Markings on IBCs

Greif Sweden/Nordic is the first in the market to replace ink jet markings with laser markings on Intermediate Bulk Containers (IBCs), reducing the use of solvent-based ink during production. By eliminating the use of solvents and ink, the production environment is cleaner. We also are able to reduce the weight of the IBC by one kilogram by removing the plate traditionally used for laser marking. We believe this innovation will set a new standard for markings on IBCs.

Knock Down Drums (KDD) for Remote Locations

Greif’s Knock Down Drums (KDD) offer the optimal sustainable solution for transporting steel drums to remote locations. Semi-finished drum parts are shipped and assembled locally on site with minimum people and equipment. The unique concept allows transportation of up to 1,176 KDDs in a 20’ sea container compared to 80 full finished drums, saving valuable space, optimizing transport costs and minimizing our customers' carbon footprint during longer transit times. Drums are delivered directly to our customers' filling station helping to improve efficiencies with minimum stock and less manual handling..

Lightweighting and Innovating the Shape of Jerrycans

Greif manufactured our first lighter weight 20 and 25-liter jerrycan models in 2015. This design is 15 percent lighter than the previous model while maintaining performance specifications of the previous design. Due to the reduced weight, the new jerrycans reduce materials and energy used in production by up to 15 percent and have a reduced emissions impact. In 2019, we expanded this product line to include sizes 16 and 18 liters. We now produce our lighter jerrycans in Italy, Israel, Sweden and Singapore.

ECOEX Jerrycans

COEX multilayer plastic packaging combines several layers of different plastics materials into a single structure and offers many barrier performance benefits, particularly for agrochemical and food packaging applications. However, when reground, COEX plastics can only be used in low performance applications. In response to our customers’ need for recyclable packaging with superior barrier performance, we created our ECOEX line of jerrycans. The ECOEX technology enables Greif to produce an innovative, multilayer jerrycan that can be recycled through regrinding processes to produce high performing, UN Certified jerrycans and bottles. ECOEX also reduces costs for our customers who typically pay an increased collection fee for COEX packaging collection after use. We continue to drive innovation that supports our circular economy strategy and meets our customers’ needs. The LATAM GIP team was awarded the 2021 Michael J. Gasser Sustainability Award for their contribution towards our circular economy strategy while meeting the needs of our customers.

EasyPour Concrete Forming Tubes

Greif’s high-quality 100% recycled paperboard concrete forming tubes offer superior performance for demanding concrete projects including columns, footings, piers and other structures. EasyPour tubes are one example of our efforts throughout 2021 to commercialize new product lines that replace virgin-based products with recycled material products and remove plastic by incorporating our aqueous-based barrier coatings. EasyPour tubes also provide our customers with products that have improved end-of-life solutions, thereby advancing our circular economy strategy. EasyPour’s built-in weather shield technology provides moisture resistance and increased strength and durability. EasyPour tubes are LEED® qualified, made of 100% recycled paperboard produced by Greif mills and are fully recyclable and repulpable.

A Lighter Approach

In order to respond to customer demands to remove weight and optimize transportation costs, our Greif Latin America colleagues designed a novel plastic drum innovation using a never seen before facetted side-wall approach for large plastic drums. This improvement removed up to 14 percent of the resin in the drum while maintaining performance. Not only does the design reduce raw material usage, it also optimized pallet utilization due to its unique configuration which allows more drums to be transported in the same space as the legacy design. The faceted drum is a more sustainable solution both in reducing natural resource consumption and lowering fossil fuel-based raw material usage and CO2 emissions during transportation.

Better Branding with Drum 360

At Greif, we now have the ability to print high-resolution images directly onto steel drums using the latest print technologies. This capability is the direct result of an investment designed to meet the needs of customers who are looking for ways to differentiate their products and generate impactful packaging design to support the price point of high value products. In addition to adding value for our customers, this process eliminated the need for a standard gas oven, using LED-based UV curing during the production process. This new process saves 0.5 kilograms CO2 per drum. Greif strategically placed the new Drum 360 technology in plants close to customers who use this new technology, in the Belgium, France, Netherlands, Italy, Germany and Poland.

GCUBE Connect: Real-time Tracking for your IBCs

Greif’s GCUBE Connect solution, launched at LogiChem virtual conference, gives real time tracking information about a customer’s IBC through the application of an Internet of Things-based device. A customer-based dashboard displays in real time where an IBC is sited, the level of the filled product and the environmental temperature. This dashboard allows customers to plan in advance for deliveries of filled product and the arrival of new IBCS, as well as schedule collections of empty IBCs. GCUBE Connect also supports better management of residue in the IBCs. Each IBC that enters the facility is automatically weighed to determine how much residue is in the container to determine how it will be treated. This innovation pairs well with Greif France’s ability to pick up and drop off reconditioned IBCs from any site along a customer’s supply chain, as opposed to one single location. Together, they simplify the logistics for the customer and increase transparency.

Meeting Consumer Demand for More Sustainable Packaging

Consumer demand for sustainable food and beverage packaging is increasing demand for more sustainable products. Our PPS business works with customers and partners to develop innovative products that replace virgin-based products with recycled material products or products that replace plastic from packaging with our barrier coatings. We developed the EnviroBevTM beverage carrier to replace a virgin-based product with a 100% recycled, wet-strength material for craft brewery beverage carriers. In 2021, PPS also commercialized food grade packaging—cupstock, platestock and bowls—made from recycled fiber with an aqueous-based coating. This coating replaces the polyethylene extrusion typically used in food grade packing and enables the packaging to be more readily composted or recycled. Combined, these innovations will replace 14,000 tons of virgin-based material with recycled material. The PPS innovation team was awarded the 2021 Michael J. Gasser Sustainability Award for their contribution towards our circular economy strategy while meeting the needs of our customers.

SUSTAINABILITY HIGHLIGHTS

$872 M

Revenue From Sustainability-Tagged Products

In 2021, Greif had $872,376,716 in revenue from sustainability-tagged products for Greif’s GIP business unit.

100%

Facilities Compliant With ISO Food Manufacturing Standards in NA

Through our Food Safety Initiative we are working to maintain our position as a market leader in food safety and meet emerging compliance requirements.

Inovação

- Sobre nossa empresa

- Sobre o nosso relatório

- Estratégias de Sustentabilidade

- Metas e Desempenho

- Índices de relatórios ESG

- Relatório de downloads

Why Innovation Matters

Our approach to innovation enables Greif to advance sustainable packaging and circular economy principles. As we continue to innovate, we reduce our footprint and support our customers’ desire for safer, lighter weight products and reduced transportation costs. We analyze our entire value chain—from the extraction of raw materials to our products’ end-of-life—to find opportunities to improve our products and processes. This strategy is not only the right thing to do, but provides us a competitive advantage.

Governança

Our innovation efforts focus on transforming our product portfolio by developing sustainable packaging solutions based on a set of eight environmental, social and financial sustainability criteria. Through internally-initiated solutions and collaboration with customers, our innovation efforts focus on dematerialization—producing products that are lighter weight, utilize less virgin raw materials and more recycled content—and green material substitution—identifying safer materials to produce our products, including bio-based materials—while continuing to meet performance requirements. Innovation is managed by our Global Innovation Committee, comprised of representatives from each of Greif’s business units and is responsible for driving collaboration and idea sharing across and within business units. The new committee structure facilitates idea sharing and collaboration across the enterprise, which allows ideas to serve and influence multiple business units. The committee updates Greif’s Executive Leadership Team (ELT) quarterly providing progress on innovation priorities and industry megatrends that may influence investment and overall company strategy in the future. Innovation is managed by a process that evaluates and prioritizes projects based on potential financial return, sustainability impacts and overall value to Greif and our customers.

In 2019, the Innovation Committee published the inaugural “Greif Global Innovation Trends Report” that identified six trends that are strategically relevant to Greif:

- Companies are Becoming More Environmentally Friendly

- Digitization & Automation of Manufacturing

- Digitization of Supply Chain & Logistics

- Digitization of Enterprise Purchasing & B2B Selling

- Workforce Shortages, Surpluses & Skill Gaps

- Growth Opportunities Increasing in Emerging Markets

In 2020, we began using these insights to make strategic decisions in the organization, including opportunities to develop 100 percent recycled drums and optimizing material use in intermediate bulk containers (IBC). Due to the increased pressure on companies to become more environmentally friendly, Greif has increased focus on post-consumer resin (PCR) products and reconditioning, more specifically, growth of its IBC reconditioning network. In reference to the third trend, digitization of supply chain and logistics, Greif credits digitization as a key enabler of sustainability improvements like industrial Internet of Things (IIoT), supply chain optimization, and marketing-related emissions reductions.

$362 M

Revenue from Sustainability-tagged products

In 2020, Greif had $361,984,251 in revenue from sustainability-tagged products.

The Greif Green Tool continues to be an important tool for us to communicate our innovations and sustainable products to our customers. In 2020, we continued to update the tool with our latest product information, ensuring data and product classifications are as up to date as possible. Going forward, we will continue to keep data in the tool as up to date as possible and all new product launches will be analyzed and added to our sustainable product portfolio if they meet the criteria. In 2019, Greif used the Green Tool to collaborate with a customer in Italy to identify more sustainable products for them. The analysis helped identify four projects to present to the customer – transitioning to lighter-weight jerrycans, increasing use of products with high percentages of PCR, create and coordinate closed loop packaging in Europe and test Greif’s GCUBE Track technology to optimize logistics and supply chain. The customer implemented two of these projects and will continue to evaluate the remaining for implementation in 2021.

Since its inception, the Green Tool has been used by 65 customers to evaluate the GHG emissions associated with different shipping scenarios. In 2020 we continued to engage with our customers using the Greif Green Tool providing more complex analyses in support of lowering their carbon footprint through packaging solutions. In 2020, Greif had $361,984,251 in revenue from sustainability-tagged products.

Our innovation priorities vary based on the specific needs of each of our business units and needs of the customers they serve. In 2020, our Flexible Products & Services (FPS) business continued advancing multiple sustainable product projects to reduce material use that, collectively, are estimated to generate 380 tons of material savings annually. The business unit also worked with our stakeholders to maintain our position as a market leader in food safety and meet emerging compliance requirements as part of our Food Safety Initiative.

Our Food Safety Initiative has also progressed in our Global Industrial Packaging (GIP) business. In 2019, we formalized our integrated ISO-certified food manufacturing practice program, which involves integrating basic food safety procedures into our quality management system. At the end of 2020, 90 percent of our facilities were compliant with the new standards. All facilities are planned to be compliant by the end of 2021 ultimately becoming the standard quality system used across GIP North America.

The acquisition and integration of Caraustar into our Paper Packaging & Services (PPS) operations has advanced innovation within the business unit even further. With their collaboration and capabilities, we have increased our ability to offer products made from 100 percent recycled fiber and products that are recyclable or compostable, including other Greif products such as fibre drums, environmentally smart (ES) natural paperboard and flame retardant floor board. These innovations replace over 20,000 tons of single-use plastic packaging annually. We are also proud of our automation and digital printing abilities both of which make our manufacturing operations more efficient and significantly reduce waste.

Our innovation efforts also address regionally specific needs and can go beyond our products. Greif’s Latin American (LATAM) offices are encouraging innovation in their working environment. In 2019, the team began hosting interactive and in-person innovation workshops to teach our colleagues about innovation and brainstorm not just product and process ideas, but innovations we can bring to our working environment to be a better and more attractive employer for current and future colleagues. In 2020, our LATAM team began conducting bi-weekly reviews with members of the innovation team to spread innovative practices that are already in place, identify new innovation opportunities and discuss non-product innovation opportunities to better serve our customers.

In 2021 we will continue to focus on developing our highest priority innovation initiatives, including new barrier technologies for plastics, jerrycan designs, knock down drum offerings across specific markets in LATAM, anti-counterfeiting measures and Internet of Things technologies.

Goals & Progress

Our innovation priorities continue to support our 2025 supply chain goals to reduce raw materials/logistics costs used to produce current product offerings by one percent and move from non-green to green material sourcing if it is economically feasible and doing so provides high quality products to our customers. In 2021, we will continue to analyze new and innovative products through research and development and engage our customers to inform our innovation priorities.

*Global revenue from sustainability-tagged products for Greif’s Global Industrial Packaging (GIP) business unit, including life cycle services

Laser Markings on IBCs

Greif Sweden/Nordic is the first in the market to replace ink jet markings with laser markings on Intermediate Bulk Containers (IBCs), reducing the use of solvent-based ink during production. By eliminating the use of solvents and ink, the production environment is cleaner and the weight of the IBC is reduced by one kilogram, a 6.7 percent reduction of resin. We believe this innovation will set a new standard for markings on IBCs.

Knock Down Drums (KDD) for Remote Locations

Greif’s Knock Down Drums (KDD) offer the optimal sustainable solution for transporting steel drums to remote locations. Semi-finished drum parts are shipped and assembled locally on site with minimum people and equipment. The unique concept allows transportation of up to 1,176 KDDs in a 20’ sea container compared to 80 full finished drums, saving valuable space, optimizing transport costs and minimizing our customers' carbon footprint during longer transit times. Drums are delivered directly to our customers' filling station helping to improve efficiencies with minimum stock and less manual handling.

Lightweighting and Innovating the Shape of Jerrycans

Greif manufactured our first lighter weight 20 and 25 liter jerrycan models in 2015. This design is 15 percent lighter than the previous model while maintaining performance specifications of the previous design. Due to the reduced weight, the new jerrycans reduce materials and energy used in production by up to 15 percent and have a reduced emissions impact. In 2019, we expanded this product line to include sizes 16 and 18 liters. We produce now our lighter jerrycans in Italy, Israel, Sweden, and Singapore. In Latin America, Greif designed a novel plastic drum innovation using a facetted side-wall approach. This improvement removed up to 14 percent of the resin while maintaining current performance. Due to the change in shape, this new side-wall approach optimized pallet utilization, allowing more drums to be transported in the same space. This facetted drum is more sustainable in both reducing natural resource consumption during manufacture and transportation.

Environmentally Smart (ES) Natural Paperboard

Greif released ES Natural to fulfill a customer need for more sustainable paperboard products. An advanced cleaning technology is used to produce a low density, 100 percent recycled fiber paperboard. It is FSC®, SFI®, PEFC™ Certified, FDA® compliant for dry food contact, and suitable for freezer applications. The smooth brown print surface maintains integrity during the freeze/thaw cycle and is ideal for folding cartons or other packaging options where a natural, brown color is desired.

100 Percent Recycled Paper for Fibre Drums

Traditionally, Greif uses virgin or a virgin/recycled mix of paper for its fibre drum products. Historically this was because fully recycled paper was not strong enough to meet the stringent regulatory performance demands of our customers. Recently, Greif paper scientists developed a specialized formulation for drum paper from 100 percent recycled paper. Using recycled fiber in our drums saves natural resources and eliminates waste to landfill by supplanting virgin raw materials with recycled products. Greif is in the process of certifying this new paper and plans to fully convert a portion of its fibre drum volume in 2021.

A Lighter Approach

n order to respond to customer demands to remove weight and optimize transportation costs, our Greif Latin America colleagues designed a novel plastic drum innovation using a never seen before facetted side-wall approach. This improvement removed up to 14 percent of the resin in the drum while maintaining performance. Not only does the design reduce raw material usage, it also optimized pallet utilization due to its unique configuration which allows more drums to be transported in the same space as the legacy design. The faceted drum is a more sustainable solution both in reducing natural resource consumption and lowering fossil fuel usage and CO2 emissions during transportation.

Better Branding with Drum 360

At Greif, we now have the ability to print high-resolution images directly onto steel drums using the latest print technologies. This capability is the direct result of an investment designed to meet the needs of customers who are looking for ways to differentiate their products and generate impactful packaging design to support the price point of high value products. In addition to adding value for our customers, this process eliminated the need for a standard gas oven, using LED-based UV curing during the production process. This new process saves 0.5 kilograms CO2 per drum. Greif strategically placed the new Drum 360 technology in plants close to customers who use this new technology, in the United Kingdom, Poland, Czech Republic, and France.

GCUBE Connect: Real-time Tracking for your IBCs

Greif’s GCUBE Connect solution, launched at LogiChem virtual conference, gives real time tracking information about a customer’s IBC through the application of an Internet of Things-based device. A customer-based dashboard displays in real time where an IBC is sited, the level of the filled product and the environmental temperature. This dashboard allows customers to plan in advance for deliveries of filled product and the arrival of new IBCS, as well as schedule collections of empty IBCs. GCUBE Connect also supports better management of residue in the IBCs. Each IBC that enters the facility is automatically weighed to determine how much residue is in the container to determine how it will be treated. This innovation pairs well with Greif France’s ability to pick up and drop off reconditioned IBCs from any site along a customer’s supply chain, as opposed to one single location. Together, they simplify the logistics for the customer and increase transparency.

SUSTAINABILITY HIGHLIGHTS

$362 M

Revenue from Sustainability-tagged products

90%

facilities compliant with ISO food manufacturing standards in NA

Siga-nos

Inscrever-se

© Copyright 2025 Greif. Todos os direitos reservados.

Visão geral da privacidade

| Biscoito | Duração | Descrição |

|---|---|---|

| análise de caixa de seleção de informações de cookielaw | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. O cookie é usado para armazenar o consentimento do usuário para os cookies na categoria "Analytics". |

| análise de caixa de seleção de informações de cookielaw | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. O cookie é usado para armazenar o consentimento do usuário para os cookies na categoria "Analytics". |

| cookielawinfo-caixa-de-verificação-funcional | 11 meses | O cookie é definido pelo consentimento do cookie GDPR para registrar o consentimento do usuário para os cookies na categoria "Funcional". |

| cookielawinfo-caixa-de-verificação-funcional | 11 meses | O cookie é definido pelo consentimento do cookie GDPR para registrar o consentimento do usuário para os cookies na categoria "Funcional". |

| cookielawinfo-caixa-de-verificação-necessária | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. Os cookies são usados para armazenar o consentimento do usuário para os cookies na categoria "Necessário". |

| cookielawinfo-caixa-de-verificação-necessária | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. Os cookies são usados para armazenar o consentimento do usuário para os cookies na categoria "Necessário". |

| cookielawinfo-caixa-de-verificação-outros | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. O cookie é usado para armazenar o consentimento do usuário para os cookies na categoria "Outros. |

| cookielawinfo-caixa-de-verificação-outros | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. O cookie é usado para armazenar o consentimento do usuário para os cookies na categoria "Outros. |

| cookielawinfo-caixa-de-verificação-desempenho | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. O cookie é usado para armazenar o consentimento do usuário para os cookies na categoria "Desempenho". |

| cookielawinfo-caixa-de-verificação-desempenho | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. O cookie é usado para armazenar o consentimento do usuário para os cookies na categoria "Desempenho". |

| visualizado_cookie_policy | 11 meses | O cookie é definido pelo plug-in GDPR Cookie Consent e é usado para armazenar se o usuário consentiu ou não com o uso de cookies. Ele não armazena nenhum dado pessoal. |

| visualizado_cookie_policy | 11 meses | O cookie é definido pelo plug-in GDPR Cookie Consent e é usado para armazenar se o usuário consentiu ou não com o uso de cookies. Ele não armazena nenhum dado pessoal. |

Use o Google Tradutor para escolher seu idioma na lista usando a barra de ferramentas na parte superior da página.