- Sustainability at Greif

- Estratégias de Sustentabilidade

- Metas e Desempenho

- Índices de relatórios ESG

- Relatório de downloads

Destaques

- At Greif, we have been incorporating recycled materials into our products for decades. Our Build to Last strategy demonstrates our commitment to being industry leaders in circularity.

- Advancing our product sustainability initiatives was a leading focus in 2024, particularly by creating opportunities to use post-consumer resin (PCR) and improving the recyclability of our plastic containers. Our innovative barrier coating technologies for plastic containers prevent the loss of our customers’ products while protecting the container from contamination.

- We create value for our customers by offering a broad suite of solutions that help them meet their sustainability goals.

- We continue to monitor the evolving regulatory landscape and are preparing to align our sustainability targets with new regulations as they emerge, including the EU’s Packaging and Packaging Waste Regulation (PPWR and Waste Framework Directive).

- In 2025, we expect to refine our sustainability targets based on an updated baseline, where circular manufacturing will play a key role in achieving our goals.

Por que a fabricação circular é importante

Our Build to Last strategy and business model are rooted in circular economy principles. With our extensive expertise, legendary customer service, global reach, and diverse portfolio of solutions, we are uniquely positioned to deliver innovative, sustainable, and circular products and services. Circular manufacturing is central to our efforts to meet our customers’ needs today while preparing for the future as they navigate regulatory changes, shifting consumer trends, and ambitious sustainability goals. Advancing the circular economy is essential for our business growth, colleague engagement, talent attraction, and environmental impact.

Collaboration across value chains is critical to driving a circular economy. We strive to maximize waste diversion, material recovery, and value creation for our suppliers and customers. By promoting recycled content, collecting end-of-life containers, and forming strategic partnerships, we deliver sustainable solutions that drive mutual success. Reconditioning, recycling, and increasing recycled content throughout the product life cycle reduce resource consumption, minimize waste, and lower carbon emissions.

Our Approach

Our circular economy strategy emphasizes a cradle-to-cradle approach, advancing five key circular economy principles:

- Redução do uso de matéria-prima virgem.

- Redução de resíduos e minimização do uso de recursos naturais.

- Inovação e aumento da reciclabilidade e uso de materiais reciclados.

- Alternativas baseadas em fibras para plásticos de uso único.

- Life cycle services including the collection, reconditioning, and recycling of used products.

Advancing circularity is a shared responsibility across our business and enabling functions. For example, our supply chain team integrates circularity objectives into key procurement categories like resin and steel, while sourcing managers explore innovative projects and new supply sources. These efforts embed circular principles into daily operations and help us achieve our 2030 circularity goals.

Reducing reliance on virgin raw materials is a cornerstone of our strategy. Lightweighting, downgauging, and prioritizing recycled materials are integral to our product design process. For instance, our EcoBalance product line incorporates up to 100 percent recycled high-density polyethylene sourced from post-consumer containers. Collaboration with customers and suppliers promotes the adoption of recycled and recyclable products, thereby aligning sustainability and business success.

We detail our approach and progress towards becoming a zero waste-to-landfill organization in the Desperdício seção deste relatório.

Product Portfolio

We offer packaging solutions for essential industries, including agriculture, agrochemicals, specialty chemicals, food and beverage, pharmaceuticals, and more. Our solutions embrace circular economy principles:

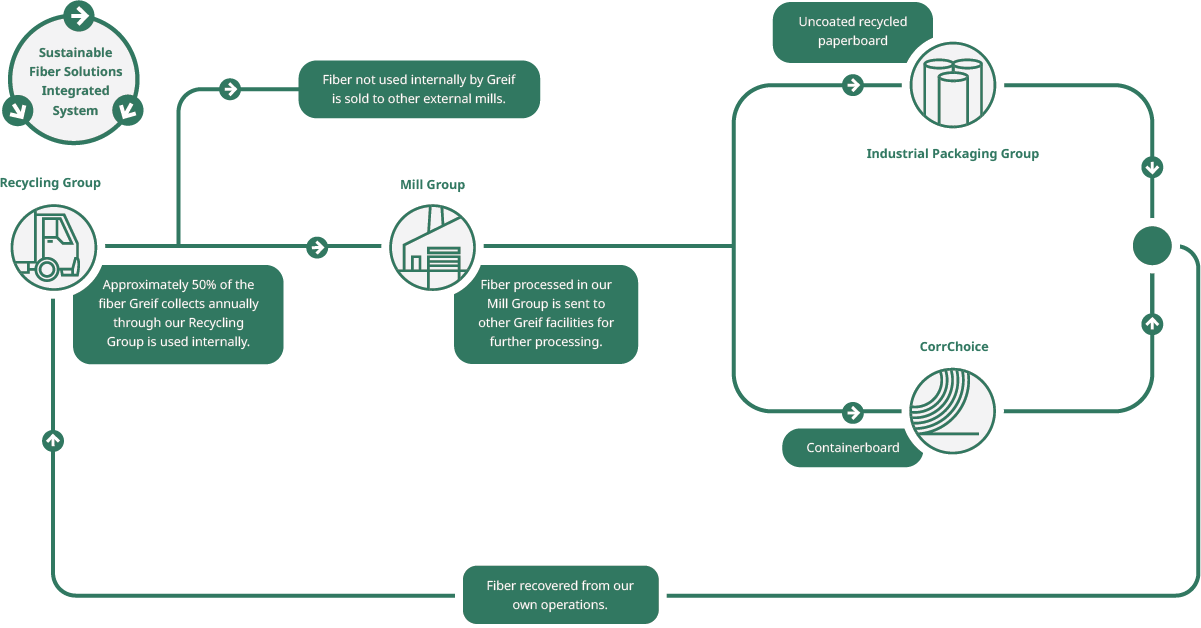

- Sustainable Fiber Solutions: Our vertically integrated solutions through the fiber packaging value chain demonstrate a circular economy. Our paper packaging solutions include fiber drums, tubes and cores, partitions, paperboard and containerboard, and corrugated products. We also develop products that replace single-use plastics with fiber-based alternatives. In 2024, 71 percent of all fiber products manufactured were sourced from recycled materials. Our Recycled Materials Group collected 3.4 million metric tons of fiber, of which 41 percent was then processed by Greif mills to produce paperboard for our paper packaging solutions.

Greif EnviroRAP

Greif EnviroRAP is 100 percent recycled paperboard with an innovative water-based, recyclable, and repulpable poly-alternative coating.

- Durable Metal Solutions: Steel drums are a sustainable packaging solution due to their infinite recyclability. They can even be reconditioned and reused multiple times before recycling. In 2024, our Life Cycle Services (LCS) network reconditioned and sold more than 1.2 million steel drums. We manufactured new steel products with approximately 5-30 percent recycled content, depending on the region.

- Customized Polymer Solutions: Our polymer solutions, including plastic drums, jerrycans, and intermediate bulk containers (IBCs) are lightweight, durable, and high performing. Our plastic packaging products are fully recyclable, supported by our comprehensive suite of barrier protection alternatives. Additionally, we reconditioned more than 1 million IBCs and 322,000 plastic drums.

Serviços de ciclo de vida

- Steel and Plastic: Our LCS network provides access to used steel, plastic, and paper products that reduce demand for virgin raw materials. In North America and Europe, we collect and recondition used steel, plastic, and IBC packaging products, making them suitable for reuse and resale. In 2024, our LCS network collected 3.6 million containers, reconditioned or remanufactured more than 2.6 million of these containers and recycled the remaining containers.

- Fiber: Greif’s Recycled Materials Group (RMG) serves as a commercial and industrial recycling partner, recycling all forms of paper and select plastics in the U.S. In 2024, RMG collected 3.4 million metric tons of material, with 41 percent used in our paper products and 59 percent sold to external mills. 86 percent of the fiber used in our paper manufacturing at our mills is sourced from recycled materials. We are a net positive recycler and a key player in the paper recycling industry.

Navigating Regulatory Landscapes

We proactively monitor evolving regulations related to circularity and waste. In 2024, we collaborated with trade associations and industry groups to stay informed, advocate for practical sustainability measures, and share insights. As new regulatory requirements emerge, we plan to refine our sustainability targets to ensure alignment. Circular manufacturing will remain central to achieving these targets.

Goals, Progress, & Performance

Metas para 2030:

- Tornar 100% dos produtos Greif recicláveis1.

- Alcançar uma média de 60 por cento de conteúdo de matéria-prima reciclada em todos os produtos2.

- Recuperar em média 80 por cento do material do mercado que enviamos para o mercado3.

We have made significant strides towards achieving our 2030 goals, particularly within our Sustainable Fiber Solutions segment. Approximately 99 percent of our fiber solution products are recyclable and, on average, are made from 71 percent recycled content. Additionally, our RMG group collects 246% of the volume of fiber products that we sell.

We are tagging products appropriately across various systems to monitor recycled content and material recovery accurately as we progress toward our goals. In 2025, this process includes automating data collection and management activities to drive operational efficiencies and real-time data availability.

Across our Customized Polymer Solutions segment we are focused on a thorough review of sourcing, equipment, and technical capabilities to evaluate our capacity to increase PCR usage within our products.

We are working towards building a global network of material recovery solutions to reach our 2030 goals while growing our global reconditioning network. In November 2024, we acquired a majority stake in Delta Containers Manchester in the United Kingdom to expand and enhance our Intermediate Bulk Container (IBC) reconditioning and recycling services across the UK and Ireland. In December 2024, through our subsidiary Centurion Container LLC, we acquired the operations of Enterprize Container Corporation (“Enterprize”). Enterprize is an industrial reconditioner in Tennessee, U.S. that provides reconditioned and rebottled IBCs as well as reconditioned plastic drums.

Trabalhando com um vasto portfólio de matérias-primas e produtos, as metas de reciclabilidade da Greif serão comparadas por peso e consolidadas em nível de empresa.

As metas de conteúdo reciclado para produtos Greif são médias mínimas comparadas em um portfólio de materiais e produtos por peso, consolidadas em nível de empresa.

[3] As metas de recuperação para os produtos Greif são médias mínimas comparadas em um portfólio de materiais e produtos por peso, consolidadas em nível de empresa.

Usando plástico reciclado na moldagem de IBC

A unidade Tri-Sure da Greif em Carol Stream colaborou com a compra da RIPS América do Norte, a RIPS Itália e quatro plantas da RIPS NA para obter 800.000 libras de resinas plásticas recicladas para uso na produção de pés traseiros/de canto e protetores de canto do IBC. Essa estratégia de fornecimento interno reduziu os custos em $100.000. A equipe também reutilizou caixas de papelão ondulado vazias para enviar os produtos reciclados que fabrica, reduzindo as compras de caixas de papelão ondulado em 84%. O projeto criou valor para a empresa e estabeleceu benefícios ambientais e financeiros, ao mesmo tempo em que fechou dois sistemas de loop interno e contribuiu para nossa economia circular desviando resíduos de aterros sanitários e encontrando um novo propósito para eles. Devido ao excelente impacto de sustentabilidade do projeto e sua capacidade de ser dimensionado para outras instalações de moldagem e moldagem por injeção, o projeto e a equipe Tri-Sure Carol Stream receberam o Prêmio de Sustentabilidade Michael J. Gasser de 2019.

Recondicionamento de Tambores Cónicos em Portugal

For the past 20 years Greif’s RIPS facility in Iberia, Portugal has been supplying customers with reconditioned conical drums, having reconditioned over 10 million drums and saving 50,000 tons of steel, 197,600 tonnes of CO2 emissions, 2,600,000 gigajoules of energy and 343,200 cubic meters of water in the process. The project was initially started as a way to help address our customers’ wish to reduce waste and lower their carbon footprint and overall improve customer satisfaction. The team collaborated with customers to understand their needs, including volume, specification requirements and safety, developed a reconditioning process and ultimately installed a reconditioning line to begin serving customers. Today, the facility serves a multitude of customers, reconditioning 500,000 conical drums and saving 5,200 tons of steel each year.

Expandindo os serviços Cradle to Cradle com investimentos e joint ventures

In recent years, Greif has made investments and established multiple joint ventures in order to expand the scale and capabilities of the reuse, recycling, and reconditioning services we provide. After acquiring a minority stake in 2020, Greif has continued its investment in Centurion Container LLC, owning 80% of the company as of April 2023, to expand our intermediate bulk container (IBC) reconditioning network in North America. After beginning a joint venture with Delta Plastics, the leading independent supplier of reconditioned IBCs in the United Kingdom, in 2020, Greif completed full-acquisition in November of 2024. Additionally, in December of 2020, Greif acquired a minority stake in LAF s.r.l., expanding IBC reconditioning services for our Italy-based customers. We look forward to working with our partners to continue to reduce our environmental impact through cradle-to-cradle solutions.

Serviços de recondicionamento de última geração em Lille

A unidade LCS da Greif em Lille, França, tomou medidas significativas para inovar a logística associada à oferta de serviços de recondicionamento para nossos clientes. Tradicionalmente, os IBCs vazios eram coletados e entregues em um único local para um único cliente. A LCS Lille começou a coletar em locais ao longo da cadeia de suprimentos de nossos clientes e, em seguida, entregar os IBCs recondicionados de volta aos nossos clientes, simplificando a logística para nossos clientes. Lille também implementou o Datamatrix, um sistema de rastreabilidade que nos permite registrar todas as etapas da produção, do recebimento à entrega, ter visibilidade das origens de um IBC e fornecer uma visão em tempo real do nosso inventário em suporte ao serviço geral aprimorado ao cliente. O Datamatrix também oferece suporte a um melhor gerenciamento de resíduos nos IBCs que eles coletam. Cada IBC que entra na unidade é pesado automaticamente para determinar quanto resíduo está no contêiner e informar como ele é tratado. Com o Datamatrix, essas informações podem ser enviadas diretamente de volta aos clientes para melhorar a forma como eles gerenciam os IBCs que estão prontos para coleta. Lille usa um sistema de circuito fechado para a água usada na limpeza de IBCs, reciclando 100% da água usada, e coleta, trata e tritura o plástico usado na fabricação de novos IBCs e tambores de plástico.

Fornecendo aos nossos clientes uma solução circular

The CorrChoice GreenGuard® A linha de produtos CorrChoice GreenGuard® fornece aos nossos clientes uma alternativa reciclável e repolpável segura para alimentos a materiais suplementares, como revestimentos plásticos. Nossa linha GreenGuard® de revestimentos de papel é segura para contato direto com a maioria dos tipos de alimentos e apresenta resistência a óleo, graxa, água, umidade e abrasão, bem como uma tecnologia inovadora de substituição de cera. Ao aplicar o revestimento em recipientes de papelão ondulado, eliminamos a necessidade de materiais suplementares usados em muitas aplicações alimentícias. Trabalhamos com nossos clientes para garantir que nossos produtos atendam às suas necessidades de manuseio seguro e protegido de alimentos, ao mesmo tempo em que fornecemos produtos de embalagem que são 100% recicláveis e repolpáveis, avançando nossa estratégia de economia circular e permitindo que nossos clientes atendam aos seus objetivos de sustentabilidade.

Siga-nos

Inscrever-se

© Copyright 2025 Greif. Todos os direitos reservados.

Visão geral da privacidade

| Biscoito | Duração | Descrição |

|---|---|---|

| análise de caixa de seleção de informações de cookielaw | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. O cookie é usado para armazenar o consentimento do usuário para os cookies na categoria "Analytics". |

| análise de caixa de seleção de informações de cookielaw | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. O cookie é usado para armazenar o consentimento do usuário para os cookies na categoria "Analytics". |

| cookielawinfo-caixa-de-verificação-funcional | 11 meses | O cookie é definido pelo consentimento do cookie GDPR para registrar o consentimento do usuário para os cookies na categoria "Funcional". |

| cookielawinfo-caixa-de-verificação-funcional | 11 meses | O cookie é definido pelo consentimento do cookie GDPR para registrar o consentimento do usuário para os cookies na categoria "Funcional". |

| cookielawinfo-caixa-de-verificação-necessária | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. Os cookies são usados para armazenar o consentimento do usuário para os cookies na categoria "Necessário". |

| cookielawinfo-caixa-de-verificação-necessária | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. Os cookies são usados para armazenar o consentimento do usuário para os cookies na categoria "Necessário". |

| cookielawinfo-caixa-de-verificação-outros | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. O cookie é usado para armazenar o consentimento do usuário para os cookies na categoria "Outros. |

| cookielawinfo-caixa-de-verificação-outros | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. O cookie é usado para armazenar o consentimento do usuário para os cookies na categoria "Outros. |

| cookielawinfo-caixa-de-verificação-desempenho | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. O cookie é usado para armazenar o consentimento do usuário para os cookies na categoria "Desempenho". |

| cookielawinfo-caixa-de-verificação-desempenho | 11 meses | Este cookie é definido pelo plug-in GDPR Cookie Consent. O cookie é usado para armazenar o consentimento do usuário para os cookies na categoria "Desempenho". |

| visualizado_cookie_policy | 11 meses | O cookie é definido pelo plug-in GDPR Cookie Consent e é usado para armazenar se o usuário consentiu ou não com o uso de cookies. Ele não armazena nenhum dado pessoal. |

| visualizado_cookie_policy | 11 meses | O cookie é definido pelo plug-in GDPR Cookie Consent e é usado para armazenar se o usuário consentiu ou não com o uso de cookies. Ele não armazena nenhum dado pessoal. |

Use o Google Tradutor para escolher seu idioma na lista usando a barra de ferramentas na parte superior da página.