- Sustainability at Greif

- Nachhaltigkeitsstrategien

- Ziele und Leistung

- ESG-Reporting-Indizes

- Bericht-Downloads

Highlights

- Greif’s Build to Last Strategy and Protecting Our Future mission embed climate considerations into our day-to-day decision-making and long-term strategic planning.

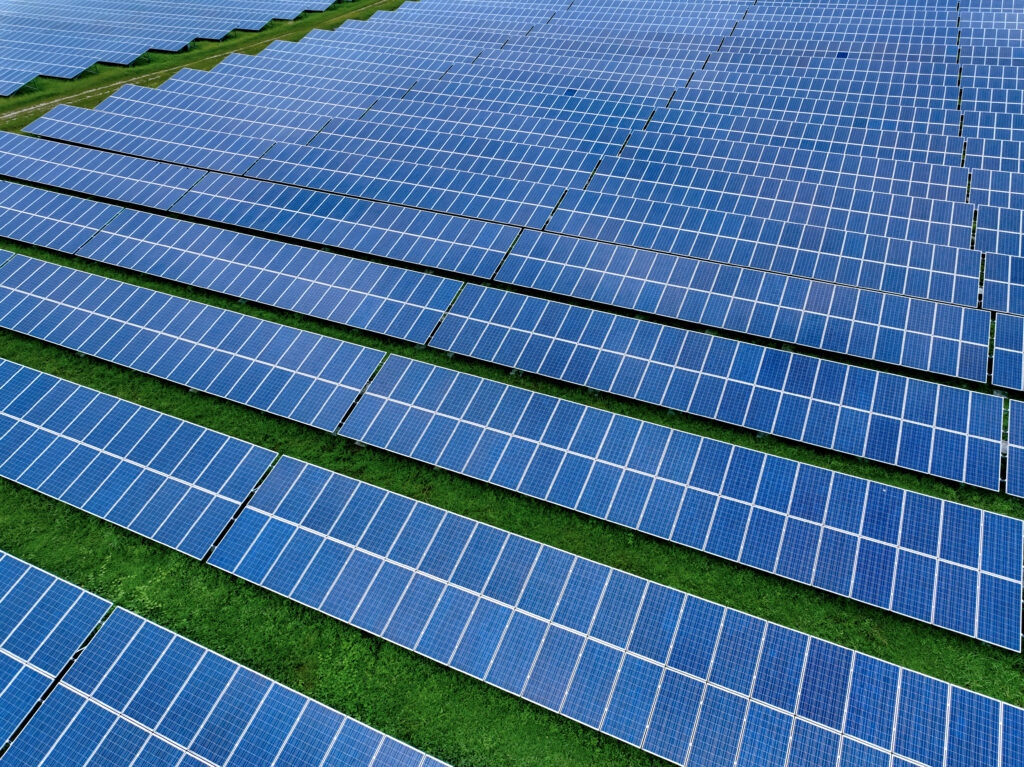

- We executed a virtual power purchase agreement (VPPA) with Enel Green Power España for 100 GWh of renewable energy annually, enough to offset approximately 65 percent of our electricity consumption in Europe.

- Greif’s land management subsidiary, Soterra, generated 59 percent of its revenue from nature-based solutions and renewable energy initiatives in 2024. We added geological sequestration, utility-scale solar installations, and development of Improved Forest Management carbon offsets to our sustainable forest management practices.

- Greif refined our Scope 3 emissions reduction methodology by conducting a thorough gap analysis to improve the quality of the data and identify new opportunities to engage with our value chain partners to reduce emissions.

- In 2024, our combined Scope 1 and Scope 2 (market-based) greenhouse gas (GHG) emissions were 1,120 thousand metric tons CO2e, compared to 1,108 thousand metric tons in 2023.

Warum eine Klimastrategie wichtig ist

Our robust climate strategy is driven by our belief that it is our responsibility to reduce our impact as a manufacturing company. This is also crucial to building and maintaining relationships with our colleagues, customers, partners, and shareholders. Climate change is a top priority for our customers, many of whom have set ambitious climate goals and are working to foster transparency across their operations and value chains. We aim to be the trusted partner that supports our customers in achieving these goals by using data-driven decision-making to provide guidance and recommendations around sustainable solutions. Our climate strategy is integrated into every facet of our business, with an emphasis on driving projects that reduce our emissions. Our product portfolio, which emphasizes manufacturing innovation and performance efficiency, reflects how we are working with customers to provide innovative, low-carbon, and circular products to help them meet their goals.

Our climate strategy is also a vital part of attracting and retaining top talent, which is needed to protect our competitive advantage in the market. We recognize the value of hiring passionate colleagues early in their career and providing a culture where they can innovate and grow. At Greif, we find a strong correlation between business success and employee engagement at all levels of our organization, and our climate strategy is an important component of that process.

Our Approach

We are working to consider and reduce the carbon footprint at each stage of the life cycle of our products, from raw material extraction to end-of-life disposal. Since 2007, we have set ambitious goals to reduce our GHG emissions and energy use, most recently setting a 2030 science-aligned target to reduce our absolute Scope 1 and Scope 2 GHG emissions by 28 percent from a 2019 baseline.

Engaging Greif colleagues is an important part of our climate strategy. To empower action and transparency, every colleague has access to energy dashboards that detail usage performance and help colleagues make more informed decisions that move us closer to our goals. Via Greif University, our internal training and education platform, colleagues also have access to thousands of courses to support them on their sustainability journey. We are working to embed our climate strategy at every level of the organization and value chain because we know success will only be achieved if there is commitment from everyone.

Risikomanagement im Zusammenhang mit dem Klimawandel

Over the past three years, we have conducted several internal climate risk workshops in which colleagues from varying departments, locations, and backgrounds collaborate to identify, rank, and evaluate regulatory, market, and physical climate-related risks and opportunities. In 2023, we successfully completed a third-party physical risk assessment to deepen our understanding of the climate risks and financial impacts associated with our operations. In 2024, our efforts focused on addressing the data points from this analysis.

Our scenario analysis included three future scenarios, including global temperature increases of below 2°C (Representative Concentration Pathway (RCP) 2.6), 2 to 3°C (RCP 4.5) and over 4°C (RCP 8.5), to identify risk likelihoods and impacts to our operations. The assessment identified precipitation, flooding, and heat stress as key physical risks across our global operations. Please refer to our CDP-Bericht für weitere Informationen zu dieser Klimaszenarioanalyse.

|

Risiko / Chance |

Thema |

Beschreibung

|

|---|---|---|

|

Physisches Risiko |

Naturkatastrophe |

Große Überschwemmungen/Hurrikane/Erdbeben/Stürme usw. führen zum Verlust wichtiger oder wertvoller Produktionsanlagen (einer oder mehrerer).

|

|

Physisches Risiko |

Direkte Umweltkatastrophe |

Große klima-/wetterbedingte Ereignisse in wichtigen Anlagen wie Delta, Vreeland und Paper Mill können zu großen Umwelt- und Finanzereignissen führen und möglicherweise zu PR-/Imageproblemen führen.

|

|

Übergangsrisiko |

Mechanismen zur CO2-Bepreisung |

Vorschriften zur CO2-Bepreisung, wie Emissionshandelssysteme und CO2-Steuern, wirken sich auf Greif in einigen Märkten (Europa und Nordamerika) aus und könnten auch in anderen Regionen eingeführt werden. Dies schlägt sich in erheblichen und wachsenden Kosten nieder.

|

|

Übergangsrisiko |

Ineffiziente Investitionen / Kapitalplanung |

Fehlen die Ressourcen, um die Auswirkungen regulatorischer Änderungen auf strategische Entscheidungen und Investitionen vollständig zu verstehen, kann dies zu einer suboptimalen Kapitalallokation führen. Dies kann dazu führen, dass Anlagen schneller veralten als erwartet und der ROI niedriger ausfällt als erwartet.

|

|

Übergangsrisiko |

Belastbarkeit / Produktionskontinuität |

Außergewöhnliche organisatorische Fähigkeiten und die damit verbundene Belastbarkeit, Vorbereitung und Agilität des Unternehmens werden es Greif ermöglichen, die Produktion schneller wieder aufzunehmen und Kollegen, Kunden und Gemeinden im Laufe der Zeit besser zu unterstützen, falls Störungen und Katastrophen häufiger auftreten sollten.

|

|

Risiken und Chancen des Übergangs |

Veränderte Kundenpräferenzen

|

Die Nachfrage nach nachhaltigen Produkten steigt. Das Risiko, dass Greif nicht schnell genug auf die zunehmende Verwendung von Recyclingmaterialien in Produktionsprozessen reagiert, könnte die Nachfrage nach Greifs Produkten und Dienstleistungen verringern. Darüber hinaus können klimabezogene Vorschriften, die die Endmärkte für Greif-Produkte einschränken, wie etwa die Öl- und Gasindustrie, das Geschäft von Greif einschränken, indem sie die Nachfrage nach seinen Produkten und Dienstleistungen in Schlüsselmärkten verringern. Greif kann diese Gelegenheit nutzen, indem wir unser nachhaltiges Produktportfolio schnell erweitern.

|

| Übergangsmöglichkeit | Auswirkungen auf das Recyclinggeschäft von Greif | Klimaszenarien mit höheren Ambitionen basieren auf der Erhöhung der Recyclingquoten für Stahl und Kunststoff. Bei entsprechender Positionierung könnte Greif den Umfang seiner derzeitigen Aufbereitungspraxis erhöhen. |

|

Übergangsmöglichkeit |

Widerstandsfähigkeit

|

Außergewöhnliche organisatorische Fähigkeiten in Verbindung mit Geschäftsstabilität, Vorbereitung und Agilität werden es Greif ermöglichen, die Produktion schneller wieder aufzunehmen und Kollegen, Kunden und Gemeinden im Laufe der Zeit besser zu unterstützen, falls Störungen und Katastrophen häufiger auftreten sollten. |

Bitte besuchen Sie die Risikomanagement Abschnitt, um mehr über unseren Unternehmensrisikomanagementprozess zu erfahren.

Klimastrategie und Dekarbonisierungs-Roadmap

Renewable energy and energy efficiency are key pillars of our climate strategy. In 2024, we increased our focus on procuring renewable energy via VPPAs and on-site solar development. To reduce carbon impacts beyond our value chain, we also leveraged nature-based solutions like geologic carbon sequestration and improved forest management offsets. Please visit the Der Natur den Vorrang geben section of the report to learn more about our nature-based solution efforts.

Erneuerbare Energien

Renewable energy procurement is core to our decarbonization strategy. Meeting the long-term energy-related challenges associated with climate change requires a meaningful shift towards renewables, such as solar, biomass, and wind energy. We strive to identify high-impact opportunities to catalyze our clean energy transition. Since 2016, we have increased our sourcing of renewable energy from both on-site and off-site locations. Greif facilities in North America, Brazil, Chile, China, the Czech Republic, Israel, and the Netherlands are powered by renewable energy, and we recently added rooftop solar to our Singapore facility. Of Greif’s total energy consumption in 2024, 16 percent (892 MWh) came from renewable energy sources such as biomass and solar energy. We will continue to identify and capitalize on additional opportunities to procure renewable energy.

Over the past three years, we conducted an extensive exploration of renewable alternatives to overhaul our electricity and natural gas consumption. As Greif’s Scope 2 emissions make up about half of our total Scope 1 and 2 emissions, switching to renewable energy would eliminate a significant portion of our overall emissions. In 2024, we signed a pivotal contract with a developer for a large VPPA project in Spain, to supply renewable energy for our European operations.

Virtual Power Purchase Agreement with Enel Green Power España

In 2024, Greif announced the signing of a virtual power purchase agreement (VPPA) with Endesa’s renewable subsidiary, Enel Green Power España (EGPE). Through the VPPA, Greif will purchase approximately 70 percent of the projects’ output, which will lead to approximately 100 GWh annually and measurable progress towards our long-term sustainability and climate goals. The solar VPPA is a significant step toward achieving a reduction of our Scope 1 and 2 greenhouse gas emissions by 28 percent by 2030, compared to a 2019 baseline. The renewable electricity generated by the project represents approximately 65 percent of Greif’s Scope 2 emissions in Europe and approximately 3 percent of our global Scope 1 and 2 emissions. By adding renewable energy to the Spanish grid, this initiative drives meaningful emissions reductions and supports a cleaner energy future. To read more about this project, please see the press release.

We are also working to increase renewable energy adoption via solar lease development. Greif is rapidly scaling our solar programs, with 50,000 acres of Soterra-managed land included in lease options with 13 different solar energy developers working on 22 projects. One project, a 100 MW solar farm in Louisiana, started construction in 2024. Please visit the Der Natur den Vorrang geben section of the report to learn more about our renewable energy procurement efforts.

Energieeffizienz

The role of energy efficiency in capital deployment is key to achieving our energy usage goals. We incorporate ESG criteria into our capital allocation system, placing priority on cost savings, reduced energy consumption, minimized raw materials usage, and improved health and safety for both people and products.

Greif colleagues regularly look for new opportunities to advance technology and conserve energy as part of our culture of continuous improvement. Our energy efficiency projects include equipment upgrades and process optimizations designed to strategically curb energy demand. In 2024, we implemented 58 energy efficiency projects, saving an estimated 35,000 MWh. Additional energy efficiency projects are routinely initiated by Greif’s Lean Six Sigma program.

Another success for the company has been our focus on LED lighting retrofits. We are actively working to retrofit our facilities to at least 80 percent LED lighting to conserve energy, reduce emissions, and create a safer and more pleasant work environment for Greif colleagues.

Energy Efficiency Across Our Operations

Throughout 2024, teams at our facilities drove innovative projects that demonstrate excellence in energy efficiency, cutting energy costs, improving efficiency, and support our sustainability goals. Greif Singapore converted a lithographic coating oven into an internal-lined ends line with an automated spraying system. The project is estimated to save more than 550 MWh per year while improving operational efficiency and capacity. Greif Saudia Arabia installed a logic timer system to manage two motors, controlling an automatic shut off during changeovers, breaks, and other periods of inactivity. These are just two examples of our colleagues’ efforts to integrate sustainability and business objectives into our operations.

For more information about our energy efficiency projects, please see sections 7.55 of our 2024 CDP Climate Response.

Kreislaufwirtschaft

At the heart of our climate strategy is an emphasis on circularity, specifically increasing the recyclability of our products, expanding our reconditioning network, implementing downgauging techniques, increasing the use of recycled raw material content in our products, and effectively managing waste.

In addition to reducing Scope 1 and 2 emissions, circularity initiatives also reduce our Scope 3 emissions linked to raw material extraction and converting, transportation, and waste sorting and processing and end of life management of our used products. Additionally, these initiatives minimize the amount of material we send to a landfill, thereby decreasing our production of landfill gas, an especially potent mix of greenhouse gases released during decomposition. We currently divert 87 percent of our waste away from landfills and aim to increase that percentage where possible.

Bitte besuchen Sie die Abfall section to learn more about our waste management efforts. Please visit this report’s Zirkuläre Fertigung Und Innovation Abschnitte, um mehr über unsere Bemühungen zur Förderung der Kreislaufwirtschaft zu erfahren.

Supply Chain Emissions

Through our Global Supply Chain (GSC) Sustainability Program, we operationalize our commitment to reduce carbon emissions throughout our supply chain. Reduction projects are prioritized and embedded into three key areas of influence: energy procurement, logistics networks, and raw material sourcing.

Our energy procurement managers lead or collaborate in our renewable energy sourcing projects. Sourcing managers identify opportunities for emissions reduction through supplier collaboration, product ideation and trials, and purchasing decisions. Our logistics managers manage projects to increase efficiency in our global transportation and logistics networks.

In 2024, we conducted a thorough analysis of our Scope 3 emissions to develop a pipeline of strategic reduction activities and projects for the medium- to long-term. We evaluate projects based on our level of influence and impact, prioritizing projects we can directly execute within our organization. We are incorporating indirect projects into engagement plans we are building to inform our work with carriers, suppliers, and third-party partners.

Bitte besuchen Sie die Globales Supply Chain Management Abschnitt, um mehr über unsere Arbeit entlang unserer Lieferkette zu erfahren.

Goals, Progress, & Performance

Ziele für 2030:

- Reduzieren Sie die absoluten Treibhausgasemissionen (Scope 1 und Scope 2) um 28 Prozent gegenüber dem Basiswert von 2019.

- Reduzieren Sie unseren Energieverbrauch für jede Produktionseinheit um 10 Prozent gegenüber dem Basiswert von 2019.

We partnered with a third party in 2020 to conduct an evaluation of our ability to achieve a Science Based Target Initiative (SBTi) aligned goal. The analysis led to Greif’s public commitment to a 28 percent reduction in absolute Scope 1 and Scope 2 emissions by 2030, based on a 2019 baseline. Aligned with prevailing climate science, this target aims to limit global warming below 2°C. While we are not yet able to provide a detailed analysis of our absolute progress against this goal due to acquisitions and ongoing data improvements, our 2024 Scope 1 and Scope 2 (market-based) absolute emissions increased by about 1 percent compared to 2023.

In 2024, we made progress through renewable energy procurement, nature-based solutions, and energy efficiency efforts. We also analyzed our Scope 3 emissions and, though we cannot set a Scope 3 target at this point in our sustainability journey, we are working to tackle these emissions while building resiliency in our supply chain. Further, Greif took our first steps in expanding ISO 14001 certifications to additional sites. ISO 14001 provides a management system framework for Greif to integrate climate change efforts into the day-to-day operations at each site on a granular level.

An amendment to ISO 9001 certifications was introduced in 2024 which integrates climate change considerations into organizational management systems. Greif’s operations team has been working to incorporate this into our ISO 9001 certification process. We actively seek opportunities to collaborate with our suppliers, customers, and other stakeholders to reduce our emissions and advance our climate strategy.

Energie- und Treibhausgasemissionsdaten

| Geschäftsjahr 2020 | Geschäftsjahr 2021 | Geschäftsjahr 2022 | Geschäftsjahr 2023 | FY 2024 | |

|---|---|---|---|---|---|

| Total Energy Consumption (MWh) | 5,423,000 | 5,832,000 | 6,145,000 | 5,594,000 | 5,450,600 |

| Energy Reduction per Unit of Production, compared to Baseline1,2 | - | -0.30% | -2.30% | -5.50% | 3.70% |

| Geschäftsjahr 2020 | Geschäftsjahr 2021 | Geschäftsjahr 2022 | Geschäftsjahr 2023 | FY 2024 | |

|---|---|---|---|---|---|

| GHG Scope 13 | 693 | 697 | 756 | 605 | 625 |

| GHG Scope 23 (Location-based) | 590 | 557 | 565 | 494 | 476 |

| GHG Scope 23 (Market-based) | 597 | 569 | 578 | 503 | 495 |

| Treibhausgase Scope 3 | 4,148 | 4,357 | 5,019 | 5,062 | 5,144 |

| GHG Total Scope 1, 2, & 3 (Location-based) | 5,431 | 5,611 | 6,340 | 6,161 | 6,245 |

| GHG Total Scope 1, 2, & 3 (Market-based) | 5,438 | 5,623 | 6,353 | 6,170 | 6,264 |

Greif Pudahuel in Chile erreicht 100% erneuerbare Energie

Greifs Stahlwerk Pudahuel in Chile war unsere erste Anlage in Lateinamerika, die zu 100 Prozent mit erneuerbarer Energie betrieben wurde. Im Rahmen eines zweijährigen Projekts in Zusammenarbeit mit dem Energieversorger IMELSA ENERGIA konnte die Anlage ihre gesamte Stromversorgung zu 100 Prozent auf erneuerbare Quellen umstellen. Die Anlage produziert große Stahlfässer, konische Fässer und Wasserflaschen für die Märkte Chemikalien, Schmieröl sowie Lebensmittel und Getränke. Diese Umstellung fördert unsere Nachhaltigkeitsstrategie, unterstützt unser Ziel der Reduzierung der Treibhausgasemissionen bis 2030 und trägt dazu bei, die Ziele unserer Kunden zur Reduzierung der Scope-3-Emissionen zu unterstützen.

Enel X Demand Response

Seit 2011 nimmt Greif an Demand Response (DR) mit Enel X teil, einer Abteilung der Enel Group Worldwide, einem multinationalen Energieunternehmen und führenden integrierten Akteur auf den weltweiten Strom- und Gasmärkten. Enel Xs DR und die Echtzeit-Energieüberwachung ermöglichen Unternehmen den Zugang zu Marktchancen, um Flexibilität zu monetarisieren, die Betriebszuverlässigkeit zu erhöhen und Fortschritte in Sachen Nachhaltigkeit hervorzuheben. Greif hat über $4,4 Millionen an DR-Einnahmen angesammelt, darunter $1,3 Millionen in den letzten drei Jahren. Etwa 17 Greif-Anlagen sind bei DR mit Enel X angemeldet. Wir prüfen, ob Standorte für die Teilnahme an DR infrage kommen und geeignete Kandidaten sind, um unsere Teilnahme am Programm auszuweiten.

LATAM Tigre Energiestudie

Greifs LATAM-Standort Tigre führte eine multidisziplinäre Bewertung aller lateinamerikanischen Werke durch, um den Energieverbrauch pro produzierter Einheit bis 2025 um 6% gegenüber dem Basiswert von 2019 zu senken. Alle Maschinen, Peripherieteile, allgemeine Geräte und Elemente, die Strom verbrauchen, wurden identifiziert und bewertet. Dabei wurden in ganz LATAM 447 Energieschwerpunkte ermittelt. Aus diesen Schwerpunkten wurden 70 strategische Energieprojekte ermittelt. Bis November 2023 wurden in LATAM 6 Energieeffizienzprojekte abgeschlossen, die zu einer Energiekosteneinsparung von $29.300 pro Jahr und einer Reduzierung des Energieverbrauchs um 63.000 Kilowattstunden pro Jahr führten.