Warum eine Klimastrategie wichtig ist

Greif integriert seine Klimastrategie in alle Aspekte seiner Betriebsabläufe, um sicherzustellen, dass wir Emissionen reduzieren und den Klimawandel in vollem Umfang bekämpfen. Wir stellen unsere Produkte so effizient wie möglich her, führen in unserem gesamten Betrieb Projekte zur Energie- und Emissionsreduzierung durch und arbeiten mit Partnern entlang unserer Wertschöpfungskette zusammen, um unsere Wirkung über unsere Unternehmensgrenzen hinaus auszuweiten. Unsere Klimabemühungen sind nicht nur Teil unserer Verantwortung als globaler Hersteller, sondern verschaffen uns auch einen Wettbewerbsvorteil.

Führung

12%

energy sourced from renewables

Das Unternehmen beweist herausragende Leistungen im Bereich Kohlenstoffmanagement, Governance, Strategie und Best Practices und übertrifft den CDP-Score von D insgesamt und im nordamerikanischen Durchschnitt.

In 2020 we implemented 73 energy efficiency projects, resulting in $724,419 of savings across our organization. These projects include replacing equipment and updating processes that reduce energy demand, such as replacing ovens, boilers and adjusting water temperatures and implementing energy efficiency practices, such as lighting and HVAC replacements. For more information about our energy efficiency projects, please see section C4.2 and C4.3b of our 2020 CDP Climate Response.

A focus in 2020 was fully integrating legacy Caraustar facilities into our energy and emissions reporting. Our legacy Caraustar facilities now account for approximately 45 percent of our energy consumption and emissions impact globally, which has changed the scale of our impact and led us to adopt new mitigation activities appropriate for our business.

In 2020, we began taking steps to better understand our broader climate impact and align to the Task Force on Climate-related Financial Disclosure (TCFD) recommendations. To begin this process, we conducted a gap analysis of our current climate management practices against TCFD recommendations to identify priority areas of focus to advance our climate strategy and modeled potential climate targets under multiple temperature scenarios. This work led to the identification and approval of our new 2030 emissions target and revealed a need to conduct a more detailed scenario analysis to better understand both our transitional and physical climate-related risks and opportunities. Our currently identified climate-related risks and opportunities are summarized below and discussed in further detail in our CDP-Antwort. In 2021 we will conduct a scenario analysis intended to deepen our understanding of these risks and opportunities, validate if they are the most material climate-related risks and opportunities and uncover additional potentially material climate-related risks and opportunities that should inform our overall climate strategy. As we conduct this work, we are pleased to include our first TCFD index in this year’s report, demonstrating our current areas of alignment with TCFD recommendations. We are looking forward to building on this progress in 2021.

|

Risiko / Chance |

Thema |

Beschreibung*

|

|---|---|---|

|

Risiko |

Impacts to production capacity |

Climate change, to the extent it produces rising temperatures inducing sea level rise, may adversely impact our ability to manufacture and transport our products. Our operations include facilities in low-lying coastal areas such as Europoort, Vreeland, and Asterweg, in the Netherlands; Malaysia; and Singapore, all which may be significantly impacted by sea level rise. |

|

Risiko |

Impacts to indirect (operating) costs |

Climate change, to the extent it impacts the price of our raw materials, fuel, transportation, and natural gas costs impacts our production and raw material supply costs. Impacts may be caused by increased regulation, changing market conditions, and impacts on our supply chain. |

|

Risiko |

Impacts to revenues due to reduced production capacity |

Climate change, to the extent it impacts the frequency and severity of precipitation extremes and related natural disasters— including wildfires and flooding—may impact our ability to manufacture and transport our products. Such climate-related extremes may impact our footprint in any geography at any time.

|

|

Gelegenheit |

Development and/or expansion of low emission goods and services |

Greif works with our raw material suppliers, transportation partners, and internal teams to develop lighter weight and more energy efficient products and provide transportation and ancillary services to help our customers reduce emissions associated with our packaging (e.g. EcoBalance, NexDRUM®). Our engagement with customers through “Voice of the Customer” interviews and surveys, materiality assessment interviews, and other avenues, confirms that our customers have a desire for low emission products.

|

|

Gelegenheit |

Shift in consumer preferences

|

As corporations, investors, and the general public become increasingly attuned to climate change issues, industrial manufacturing clients are at risk of changing public perceptions around a company’s operations and product lines. By developing products and services that decrease customers' GHG emissions and waste in their value chain Greif can set itself apart from competitors, garner market share and reinforce its positive reputation.

|

|

Gelegenheit |

Use of more efficient production and distribution processes

|

Due to potential changes in legislation/regulation, we could incur increased energy, environmental and other costs and capital expenditures to comply. However, this also affords us the opportunity to further improve our energy efficiency, thereby reducing our costs and exposure to these risks. |

Ziele und Fortschritt

2020 marked the end of our current energy and greenhouse gas goal, but not the end of our commitment to reduce our environmental impact. In 2020, we conducted a detailed analysis and evaluation with a third party of our ability to commit to a goal that would be approved by the Initiative für wissenschaftsbasierte Ziele (SBTi). We are excited to announce our commitment to reduce our Scope 1 and Scope 2 emissions by 28 percent by 2030, from a 2019 baseline. This new target is aligned with prevailing climate science to limit overall global warming to well below 2 degrees Celsius and builds upon the company’s 11 percent emissions reduction per unit of production accomplishment achieved in 2020. By the end of 2023, Greif will also complete an assessment of its Scope 3 emissions and determine the feasibility of a long-term net zero emissions aspiration in alignment with the Science-based Targets Initiative.

To achieve our new target, we will build upon our existing investments in energy efficient equipment, onsite solar power, and grid-sourced green electricity with a strategic approach that will include additional energy efficiency initiatives and sourcing of offsite, large-scale renewable energy.

Ziel 2020: 10 Prozent Reduzierung des Energieverbrauchs und der Treibhausgasemissionen pro Produktionseinheit im Vergleich zum Basisjahr 2014.

Fortschritt: As of the end of fiscal 2020, we achieved an 11 percent emissions reduction per unit of production decrease from a fiscal 2014 baseline and 1.1 percent reduction in energy consumption per unit of production from the 2014 baseline.

Ziel 2030: Reduzieren Sie die absoluten Treibhausgasemissionen der Bereiche 1 und 2 um 28 Prozent gegenüber dem Basiswert von 2019. Greif wird außerdem eine Bewertung der Emissionen des Bereichs 3 durchführen und die Machbarkeit eines langfristigen Netto-Null-Emissionsziels bis Ende 2023 prüfen.

Leistung

|

|

GJ |

GJ |

GJ |

Geschäftsjahr 2017 |

GJ |

GJ |

GJ |

|---|---|---|---|---|---|---|---|

|

Energie |

|||||||

|

Gesamtenergieverbrauch (MWh) |

3,228,000 |

3,057,000 |

3,009,000 |

3,058,000 |

3,103,200 |

5,398,000

|

5,423,000

|

|

% Energieeinsparung pro Produktionseinheit |

(Baseline year) |

N / A |

1.8% |

3.1% |

4.2% |

0.0%

|

1.1%

|

|

% Reduction in Emissions per Unit of Production** |

(Baseline year) |

6.0%

|

2.0% |

8.4% |

10.3% |

11.0%

|

11.0%

|

|

Treibhausgasemissionen (Tonnen) |

|||||||

|

Geltungsbereich 1 |

362,300 |

322,500

|

345,700 |

367,700

|

376,700

|

675,900

|

692,900

|

|

Umfang 2 (standortbezogen) |

496,000

|

438,600

|

446,700

|

416,000

|

415,900

|

637,300^

|

589,500

|

|

Geltungsbereich 3 |

251,500

|

221,900

|

2,927,000

|

3,089,000

|

2,867,090

|

4,403,000

|

4,148,000

|

|

Gesamt |

1,109,800 |

983,000

|

3,719,400

|

3,872,700

|

3,659,600

|

5,716,200^

|

5,430,400

|

Hinweise:

- Quelle: Greif 2020 CDP Climate Response

- Energy and emissions data accounts for all legacy Greif and Caraustar facilities from 2019 forward.

- Emissions data accounts for CO2, CH4 and N2O.

- Scope 3 emissions takes into account upstream transportation and distribution. In 2017, scope 3 was expanded to include purchased goods and services, capital goods, fuel and energy related activities not included in Scope 1 and 2, including waste generated in operations, business travel, employee commuting and end of life treatment of sold products. Data based on legacy Greif Facilities only.

- Treibhausgas-Verifizierungserklärung 2020

**Unsere prozentuale Emissionsreduzierung pro Produktionseinheit sank zwischen dem Geschäftsjahr 2015 und dem Geschäftsjahr 2016 aufgrund erhöhter flüchtiger Emissionen aus unserer Papierfabrik in Riverville, Virginia, und der Gesamtemissionen aus unserer Papierfabrik in Massillon, Ohio. Aktualisierte Emissions- und Treibhausgaspotenzialfaktoren trugen ebenfalls zu dieser Änderung bei. Die Daten basieren nur auf älteren Greif-Anlagen, um die Vergleichbarkeit mit dem Basiswert von 2014 zu gewährleisten.

^ Diese Zahlen wurden angepasst, um den Dampfverbrauch in einem unserer Werke besser zu berücksichtigen.

Emissionsreduktionsgutschriften (ERCs)

Um Greifs Emissionen von Luftschadstoffen wie Stickoxiden (NOx) und flüchtigen organischen Verbindungen (VOCs) zu senken, ersetzten Greifs Kartonfabriken in Los Angeles, Kalifornien und Fitchburg, Massachusetts ihre Ausrüstung durch energieeffizientere Technologie, die Luftschadstoffe reduziert. Allein die Betriebe in Massachusetts sparten in einem einzigen Jahr 96 Tonnen NOx und 27 Tonnen VOCs ein. Die Modernisierungen ermöglichten es Greif auch, von den Cap-and-Trade-Programmen in Kalifornien und Massachusetts zu profitieren, die ERCs für ähnliche Aktivitäten bereitstellen. Im Jahr 2019 erhielt Greif im Rahmen dieser Programme $1.037.100 ERCs.

Umstellung auf Elektrostapler

As part of our overarching goal of having more efficient and sustainable equipment, in 2018 we began transitioning our fleet of forklifts from being powered by combustion gasoline to electricity, which reduces our forklift emissions approximately 50 percent. Through 2020, we have converted 99 percent of our forklifts in EMEA to electricity power while we reduced fleet size by 17 percent and realized a cost savings of $352,000 in 2020. In North America, we have replaced 2 percent of our fleet and saved $250,000 in 2020. Due to the success of the program, and in support of our overall Renewable Forklift Policy, the program will continue to be rolled out globally. In addition to the environmental benefits, the transition provides a safer working environment for our colleagues by reducing the need to keep containers of gasoline in our facilities.

Energieeffizienz in der Produktion

Greif hat kürzlich eine Großinvestition in eine neue Blasformmaschine getätigt, mit der Greifs Kunststoffkanister in unserem Werk in Casablanca, Marokko, hergestellt werden. Die neue Maschine verbraucht bis zu 30 Prozent weniger Energie als Maschinen der älteren Generation und bietet gleichzeitig eine deutlich höhere Produktivität. Die neue Anlage steigert die Produktionskapazität unserer Ein- bis Fünf-Liter-Flaschen um bis zu 25 Prozent und ist darauf ausgelegt, den Rohstoffverbrauch zu optimieren und zu reduzieren, wodurch der Umweltnutzen der Maschine über den Energieverbrauch hinausgeht.

Das Team in Marokko hat auch andere Projekte zur Energieeffizienz umgesetzt. Dazu gehören die Beseitigung von Luftlecks in unseren Kunststoff- und Stahlwerken, der Austausch hydraulischer Extruder durch elektrische an vier Maschinen, die Modernisierung alter Anlagen und der Austausch von Gleichstrommotoren durch Wechselstrommotoren an mehreren Blasformmaschinen, die dazu beitragen, unseren Energieverbrauch deutlich zu senken.

Förderung erneuerbarer Energien

Renewables, such as biomass, solar and wind energy, will play a major role in addressing the challenges of climate change over the long term. We are committed to testing and expanding the use of renewable energy technologies across our global operations when doing so is economically viable and in the best interest of our stakeholders. Across our global operations, we have installed over 6,800 solar panels capable of 1.84 million kilowatt hours of solar production and annual savings of $120,000. Due to our continued investment, renewables now account for 12 percent of Greif’s energy use.

In North America, we have installed more than 2,000 solar panels in seven facilities, delivering 640,000 kilowatt hours (kWh) of energy and saving more than $100,000 annually.

Im Jahr 2016 begannen drei unserer größten brasilianischen Werke damit, ihren Strom teilweise aus erneuerbaren Ressourcen zu beziehen. 2017 weiteten wir das Programm auf drei weitere Werke in Brasilien aus, wodurch wir die Emissionen um 70 Prozent reduzierten und jährlich $1,4 Millionen USD einsparen konnten.

Im April 2017 wurde die Installation von Solarmodulen in Greifs Shanghaier RIPS-Anlage abgeschlossen. Dadurch wurden 15,4 Prozent des Stroms der Anlage in erneuerbare Energie umgewandelt und jährlich über $16.000 USD eingespart. In unseren Betrieben in China beziehen wir über Energieabnahmeverträge erneuerbare Energie aus 4.800 Solarmodulen.

Unser FPS-Betrieb in der Türkei produziert mithilfe von Windturbinen und Windmühlen über zwei Millionen Kilowattstunden Energie.

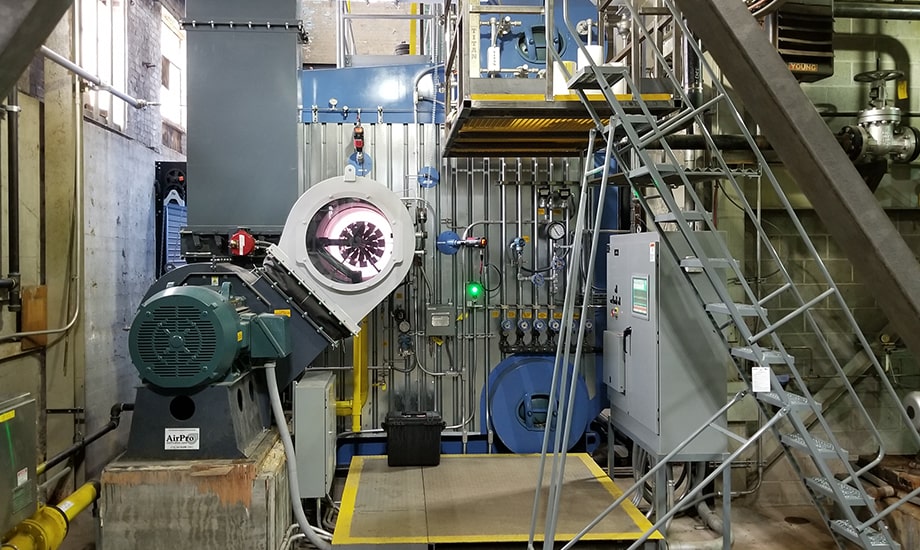

Replacement of Boiler with 10% Energy Efficiency Improvement

Greif’s paperboard mill in Fitchburg, Massachusetts was operating a boiler that was initially installed to support two paper machines. The boiler was oversized for the mills operating needs and as a result was not operating as efficiently as possible and causing reliability problems. In 2019, a new boiler was purchased to allow for improved steam efficiency and reliability. Due to these improvements, the new boiler is expected to generate 15,811,200 kWh and $324,000 savings annually.

EPAs SmartWay-Transportpartnerschaft

Um die Logistik umweltbewusst zu gestalten, verwendet Greif, wenn möglich, Spediteure, die durch die SmartWay-Initiative der EPA zugelassen sind. Wir schließen die SmartWay-Zertifizierung in unseren Zertifizierungsprozess für neue Spediteure ein. Greifs SmartWay-zertifizierte Spediteure decken 77 Prozent der gesamten zurückgelegten Meilen ab.