Highlights

- Our business continuity, automation and digitization efforts ensure we deliver on our vision of legendary customer service by consistently providing the highest-quality products and services at every Greif location, even under shifting business conditions and supply chain challenges or following a natural disaster.

- Our Enterprise Automation Strategy plays a significant role in our business continuity efforts and delivers on our Build to Last Strategy, enabling Greif to reduce harm to our colleagues, deploy standardized solutions, enhance cost-competitiveness and be better positioned to serve our customers.

- In April 2023, we initiated a pilot project for our Customer Digital Platform at a North American facility. Following the successful pilot launch, we have been diligently working on scaling the platform and expanding its accessibility to a broader customer audience.

Why Business Continuity, Automation & Digitization Matters

Ensuring business continuity is pivotal for Greif’s overarching resilience and success and is part of every aspect of our corporate strategy. It guarantees the seamless provision of products and services, upholding customer trust and satisfaction. Comprehensive continuity plans enable Greif to minimize downtime, mitigate financial losses and swiftly recover from disruptions, reinforcing our long-term stability.

Automation and digitization play pivotal roles in achieving our goals of high-quality products and excellent customer service. Digitization enables seamless information-sharing while advancing automation allows us to swiftly adjust manufacturing processes to meet customer demands amid shifting business conditions and supply chain challenges or following a natural disaster.

Governance

The Global Operations Group (GOG) is responsible for our Enterprise Automation Strategy, continuous improvement, engineering and capital deployment, operational execution and business continuity processes. Led by our Senior Vice President, Global Operations Group, the GOG is instrumental in developing business continuity plans for each facility. Additionally, it assesses the effectiveness of implemented plans and integrates insights gained from incidents that may impact business continuity. With GOG at the lead, we will continue enhancing the Greif Business System 2.0 in FY25 to include global automation, capital execution excellence and business continuity planning.

With an expansive global network of 199 production facilities, Greif manufactures products to meet customer specifications at multiple sites, offering flexibility in production changes based on inventory, customer needs or unforeseen shutdowns. We track raw materials and finished goods across our facilities using our centralized inventory management and sales and operations planning processes. Each facility sources raw materials from diverse suppliers to prevent production stoppages from supplier delays or shortages. We also leverage our existing Natural Disaster Recovery Protocol to continue delivering on our commitments to our customers. This protocol requires all products to be co-produced at multiple facilities and that each facility maintain an alternate supplier list for the facility’s top 35 materials to support continuity of supply.

Our Global Industrial Packaging (GIP) business’s Disaster Recovery/Business Continuity Program strategically mitigates risk and supports business continuity by incorporating inventory and production redundancy capabilities, facility risk assessments and proactive labor relations. The program details our process to identify customer orders susceptible to disruption in case of a facility disaster, identifying alternative products meeting customer specifications and facilities capable of producing them. In 2023, we conducted 17 random mock disasters to assess customer impact and ensure program comprehension and ease of implementation. This program and our Disaster Recovery Business Continuity Policy are reviewed annually and administered by sales, customer service, operations, marketing and logistics colleagues, with support from business unit leadership.

Strengthening Our Business Through Business Impact Analyses

In 2022, Greif performed Business Impact Analyses (BIAs) across nine business functions to identify critical business processes, impact levels, recovery priorities and required resources. As part of the BIAs, we conducted interviews with key business function owners and IT, held knowledge sharing sessions with the Greif Business Continuity team and developed summary reports with actionable recommendations and next steps planned for 2024. Results of the BIAs were shared with Greif management where necessary. By understanding our business requirements and needs for recovery through the BIAs, we are better able to support ongoing business continuity.

To complement our Disaster Recovery/Business Continuity Program, which focuses on operational risks, in 2023, we developed a Global Business Continuity Playbook to address business continuity risks such as cyberattacks, natural disasters, fires and pandemics. As part of developing the playbook, we implemented comprehensive testing, including simulations of mock disasters, to ensure the integrity of our systems in real-world scenarios.

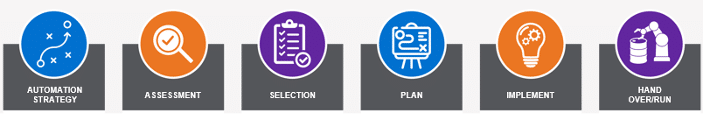

Greif’s Enterprise Automation Strategy plays a significant role in our business continuity efforts and delivers on our Build to Last Strategy. By leveraging automation, we can effectively reduce harm to our colleagues, deploy standardized solutions, enhance cost-competitiveness and better serve our customers. Automation across our operations promotes process standardization in alignment with our One Greif approach. Standardized automation-enabled manufacturing processes in place at various locations facilitate quicker recovery from disasters. This standardization is crucial as we navigate growth and acquisitions, ensuring seamless integration of diverse business operations.

We identified 75 automation projects in 2022 that are regularly reviewed alongside our strategy to ensure adaptability as our business needs change. Additionally, we implemented 83 projects from our Lean Six Sigma program that reduced waste, costs and risks and promoted continuous improvement across operations in 2023. Our ongoing commitment involves reviewing and implementing these projects and exploring additional opportunities across our business.

Launching a Customer Digital Platform

Digitization is essential for realizing our global customer service vision, meeting heightened expectations for product and service quality and ensuring operational resilience. With the development of our Customer Digital Platform (CDP), we began identifying elements of the Greif-customer relationship that could be digitized, streamlining processes, saving time and ultimately improving customer satisfaction. The CDP provides our customers an online platform to place, track and manage orders.

In April 2023, we launched the pilot for our CDP at a North American facility. The CDP enhances customer processes by streamlining operations, simplifying online ordering, enabling order tracking and providing product data. Following the successful pilot launch, we have been diligently working on scaling the platform and expanding its accessibility to a broader customer base. We aim to make the platform available for all customers served by our North American Global Industrial Packaging plants by the end of 2024 and scale the platform to other business units and regions.

As we continue to expand the platform and add additional features, we will also continue looking for opportunities across our business to digitize processes, foster innovation and optimize efficiency.

Our workforce is critical to ensuring business success, and we recognize the risks associated with labor disputes to business continuity. Proactively managing collective bargaining agreements on a two-to-three-year timeline, we address negotiations consistently, not just when mandated. Our agreements outline a one-month notice period for significant operational changes, with specified provisions for consultation and negotiation. Our senior leadership plays an active role in developing positive labor relations with union leaders and members in each plant.

Goals, Progress & Performance

In 2023, we began incorporating an artificial intelligence visual inspection function for products, replacing manual visual inspections in our current processes. This technology addresses the challenge of maintaining production rates and reduces human error and waste, streamlining processes and increasing our processed product.

Led by the Chief Information and Digital Officer, Greif has identified a set of flagship automation and digitization initiatives to incorporate into our multiyear IT strategy, including delivery model enhancement, intelligent and automated supply chain and innovation of smart factory components. We are also exploring an initiative to implement geo-tracking for all logistics operations in the U.S., covering both inbound and outbound activities. In 2023, we also implemented End of Line Automation for manufacturing equipment, incorporating Internet of Things linkage to provide real-time production data. This system offers insights into manufacturing throughput, quality control metrics, defect rate reporting and distribution analysis. By forecasting maintenance needs, we can effectively reduce downtime and enhance production planning, ensuring timely delivery to meet our customers’ needs.